7.16 Safe Brake Control (SBC)

The SBC function is defined according to EN 61800-5-2.

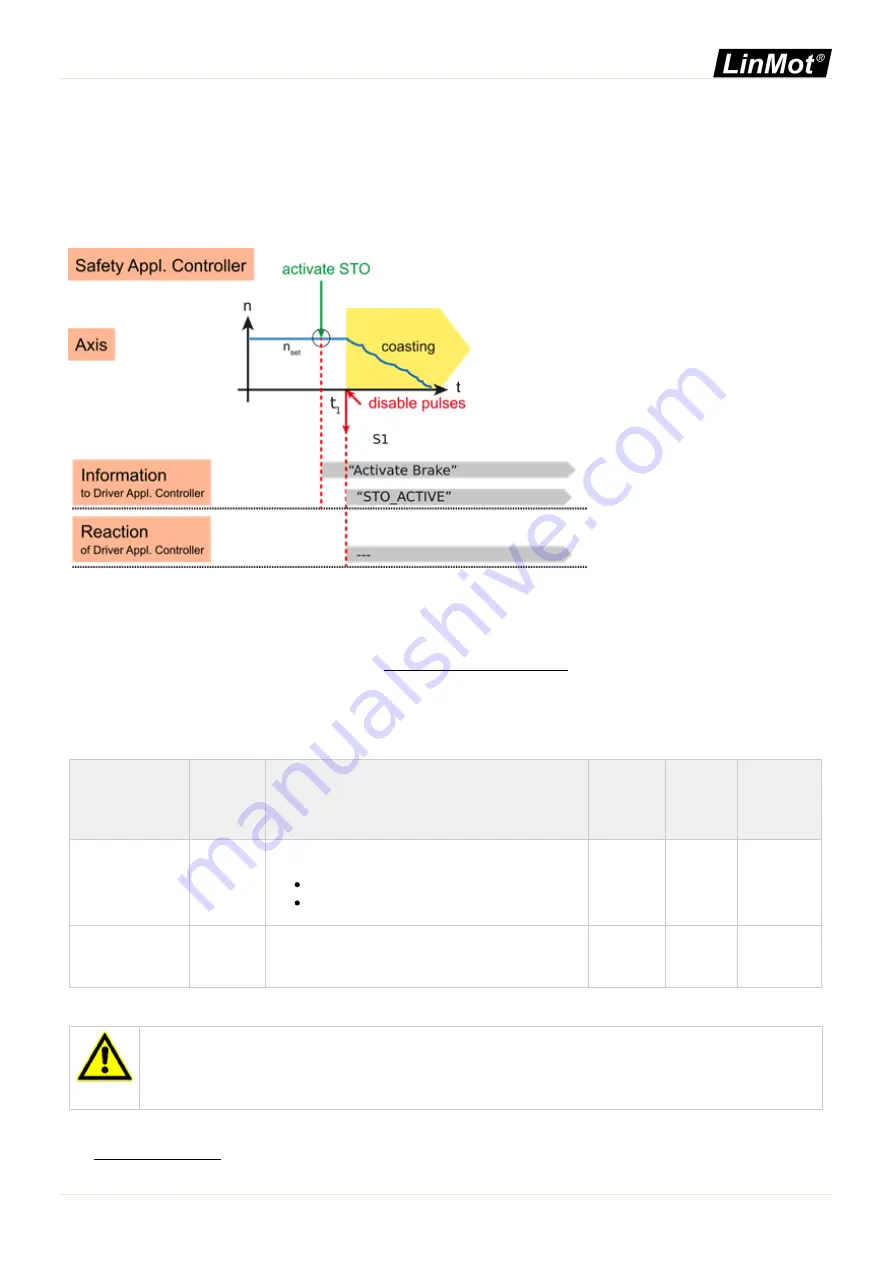

The SBC function supplies a safe output signal to control a holding brake.

On the drive, there is one output for the safe brake implemented, it is located on X50 Pin 1 (Brake+) and Pin 2 (Brake -).

The SBC can also be used with non-safe position encoders.

Figure 24: SBC

With the SBC function the monitoring of the brake controlling hardware and the presence of the brake is regularly tested.

The test checks, if the current to the brake can be turned off (the brake is in the safe state, when no current is driven).

The safe brake test (SBT) is described in chapter 7.17 - Safe Brake Test (SBT).

7.16.1 Parameters

The parameters are located under \Parameters\Safety\STO/SBC/SBT\.

Name

UPID

Type

Unit

Description

Min

Max

Typical

Brake attached

47D4h

UInt8

-

Defines if a brake is attached or not.

00h: Not Attached (Default)

01h: Attached

-

-

Not Attached

SBC STO_Delay

47D5h

UInt16

1ms

Defines the delay between brake and STO, this value is

only used if a brake is configured.

0 s

60 s

20 ms

Table 69: SBC/SBT Parameters

NOTICE

Brake Configuration

If the brake is attached on X50, also the non-safe configuration under "Brake Config", UPIDs 1716h to

1719h, 171Bh and 171Ch have to be set accordingly.

If the state of the brake output shall be displayed with the safe digital output, the configuration must be set accordingly,

see 7.13.2 - Parameters

2S Drive Systems / 0185-1174_E_1V1_SM_C1251-2S / NTI AG

0185-1174_E_1V1_SM_C1251-2S / 2021-11-26 16:43 (Rev. 12500)

Page 100 of 150