9

Product Data

Due to our policy of continuous product innovation, some specifications may change without notification.

©LG Electronics U.S.A., Inc., Englewood Cliffs, NJ. All rights reserved. “LG” is a registered trademark of LG Corp.

General Information

LG Electronic’s Inverter Scroll Chillers provide chilled water for

cooling-only, commercial air conditioning systems using air-handling

units, fan coil units, etc. The single frame 20-ton ACAH chiller uses

R410A refrigerant, applies air-cooled condenser technology; in-

cludes scroll compressors, electronic expansion valves, evaporator,

and LG Human Machine Interface (HMI); and is designed for outdoor

installation.

The ACAH chiller series includes two (2) scroll compressors to form

two (2) refrigerant cycles. Up to five (5) chillers can be interlocked

through LG’s CH3 A and B 2-wire control bus.

LG includes inverter technology in its scroll compressors and air-

cooled condenser fan motors to provide efficient operation at high

loads and in all operating areas. ACAH chillers also feature electron-

ic expansion valves, evaporators with shell-and-tube heat exchang-

ers (connected to the chilled water side), and condensers with air-

cooled fin-and-tube heat exchangers. Each refrigerant cycle includes

check valves, electronic expansion valves, refrigerant check valves,

and strainers. Human Machine Interface (HMI) controllers, built

within the ACAH chiller itself, applies LG’s unique control logic to monitor all parameters controlling the operation. These parameters can be

controlled to improve operational efficiency, and can continuously supply chilled water by adjusting to the environment.

Cooling Cycle

ACAH chillers feature high-pressure type scroll compressors. The suction vapor is separated from the high-pressure discharge area, and the

motor is installed on the low-pressure vapor area. The motor and refrigerant storage are located in the low-pressure vapor area to increase

liquid compression reliability.

Because the suction refrigerant vapor cools the motor and flows onward to the compressor, a separate device to cool the compressor is not

required. Inside the system, oil to lubricate the compressor is mixed with the refrigerant, and both the oil and refrigerant discharges during

operation. Discharged compressor oil can reduce the heat transfer efficiency if a thick layer builds up on interior walls of the condenser and

evaporator, so a device to prevent the refrigerant and oil to be discharged together is installed.

This lubrication system ensures longer life for the compressor, improves compression sealing, and provides lower sound operation. The

condenser is designed with a V-shaped heat exchanger, and an electronic expansion valve is used for efficient control in all load conditions.

The controller in the chiller is an LG exclusive, and monitors the different sensors installed to provide product protection.

For continuous supply of water, LG chillers are equipped with maximum continuous operation functions, and also provide precision control

to supply the targeted water volumes. Protection devices will immediately stop the chiller if the operation malfunctions, or a condition limit is

reached. In case of an operation malfunction, the chiller controller will display error codes to the authorized LG service provider.

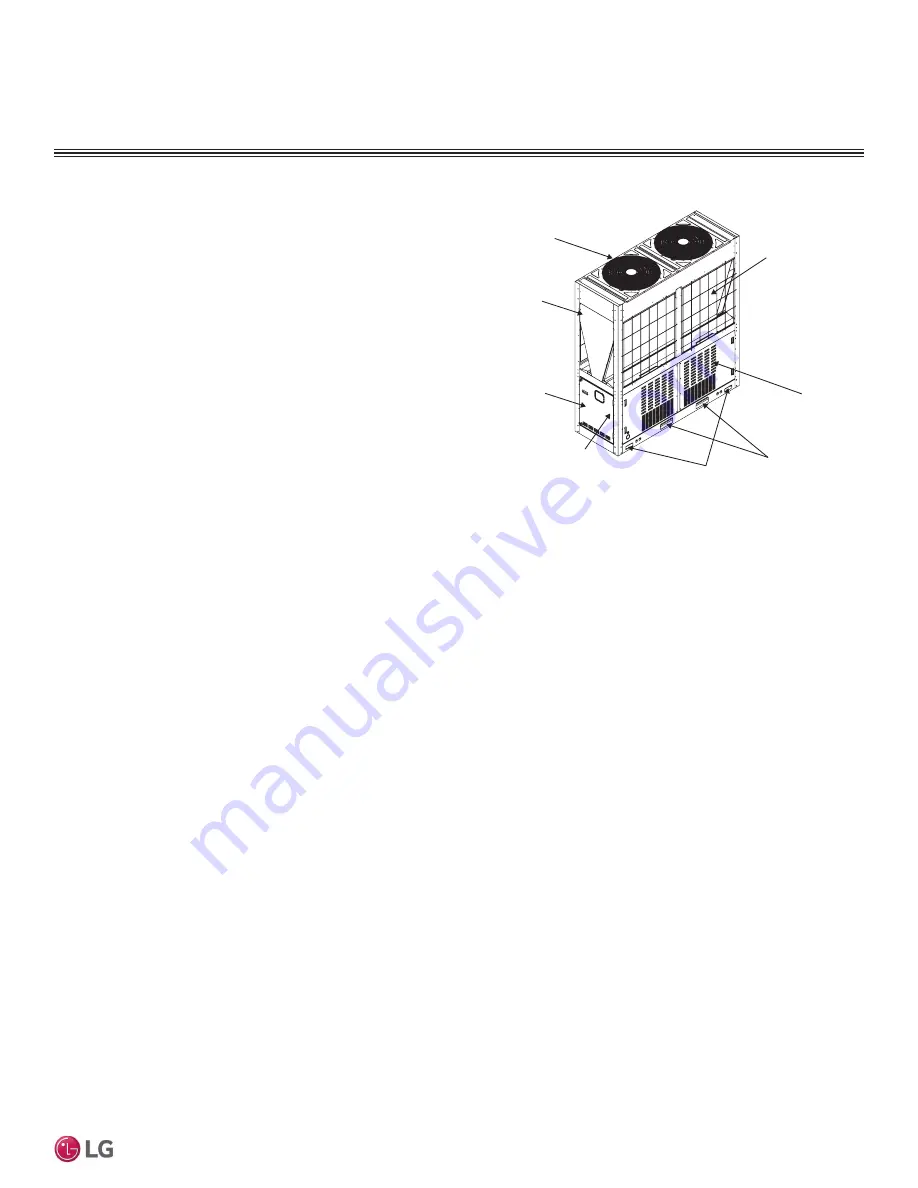

Figure 1: Example of an LG Chiller.

Fan Motor

Fin and Tube

Heat Exchanger

Main Controller Box

Sub-Controller

Box

Condenser

Cover

Side

Cover

Rope Support

Access

Forklift Access

INTRODUCTION