G 7

0

708

.USA

3

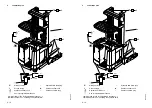

Maintenance and inspection

A thorough and professional maintenance service is one of the most important

requirements for the safe use of the industrial truck. Ignoring regular maintenance

intervals can cause the truck to break down and presents a potential danger to

personnel and equipment.

IMPORTANT

Operating conditions for the industrial truck can have a significant impact on

the life of service components.

We recommend that a customer consultant from Jungheinrich perform an on-

site operational analysis and define maintenance intervals to minimize

damage due to wear.

The indicated servicing intervals are based on single-shift operation under

normal operating conditions. For applications in dusty environments,

involving large temperature fluctuations or multiple-shift operation, the

servicing intervals must be shortened accordingly.

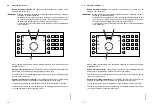

The maintenance checklist below sets out the jobs to be done and the intervals at

which they are required. The maintenance intervals are defined as follows:

W

= Every 50 operating

hours,

or at least once a week

A

= Every 500 operating

hours,

B

= Every 1000 operating

hours,

or at least once a year

C

= Every 2000 operating

hours,

or at least once a year

NOTICE

W maintenance must be performed by the owner.

When the industrial truck is being broken in - after approx. 100 operating

hours - the owner must check the wheel nuts and wheel bolts and tighten

them if necessary.

G 7

0

708

.USA

3

Maintenance and inspection

A thorough and professional maintenance service is one of the most important

requirements for the safe use of the industrial truck. Ignoring regular maintenance

intervals can cause the truck to break down and presents a potential danger to

personnel and equipment.

IMPORTANT

Operating conditions for the industrial truck can have a significant impact on

the life of service components.

We recommend that a customer consultant from Jungheinrich perform an on-

site operational analysis and define maintenance intervals to minimize

damage due to wear.

The indicated servicing intervals are based on single-shift operation under

normal operating conditions. For applications in dusty environments,

involving large temperature fluctuations or multiple-shift operation, the

servicing intervals must be shortened accordingly.

The maintenance checklist below sets out the jobs to be done and the intervals at

which they are required. The maintenance intervals are defined as follows:

W

= Every 50 operating

hours,

or at least once a week

A

= Every 500 operating

hours,

B

= Every 1000 operating

hours,

or at least once a year

C

= Every 2000 operating

hours,

or at least once a year

NOTICE

W maintenance must be performed by the owner.

When the industrial truck is being broken in - after approx. 100 operating

hours - the owner must check the wheel nuts and wheel bolts and tighten

them if necessary.

Содержание ETR 314

Страница 1: ...Operating instructions 50 452 907 ETR 314 320 u 06 06 11 09 07 08 E Manual de instrucciones...

Страница 7: ...0608 USA I 4 0608 USA I 4...

Страница 9: ...0606 USA A 2 0606 USA A 2...

Страница 24: ...D 9 0107 USA D 9 0107 USA...

Страница 26: ...D 11 0107 USA D 11 0107 USA...

Страница 103: ...0107 USA F 10 0107 USA F 10...

Страница 123: ...0708 USA G 20 0708 USA G 20...

Страница 135: ...0608 E I 4 0608 E I 4...

Страница 137: ...0606 E A 2 0606 E A 2...

Страница 152: ...D 9 0107 E D 9 0107 E...

Страница 154: ...D 11 0107 E D 11 0107 E...

Страница 162: ...E 3 0608 E 1 2 18 17 4 5 3 6 7 8 9 10 11 12 13 14 15 16 E 3 0608 E 1 2 18 17 4 5 3 6 7 8 9 10 11 12 13 14 15 16...

Страница 164: ...E 5 0608 E 1 2 18 17 4 5 3 6 7 8 9 10 11 12 13 14 15 16 E 5 0608 E 1 2 18 17 4 5 3 6 7 8 9 10 11 12 13 14 15 16...

Страница 225: ...0608 E E 66 0608 E E 66...

Страница 235: ...0107 E F 10 0107 E F 10...

Страница 255: ...0708 E G 20 0708 E G 20...