G 1

0

708

.USA

G Industrial truck maintenance

1

Operational safety and environmental protection

The checks and maintenance jobs set out in this chapter must be carried out at the

intervals specified in the maintenance checklists.

Q

wW

Operating an electric and manual industrial truck can be dangerous if

maintenance is neglected or if repairs, overhauls or settings are not carried

out in accordance with the manufacturer's instructions.

Q

wW

Any modification whatsoever to the industrial truck – and particularly to safety

devices – is prohibited. The operating speed of the industrial truck must not

be changed under any circumstances.

IMPORTANT

Only original spare parts are subject to our quality control. To ensure the safe

and reliable operation of the industrial truck, only spare parts from the

manufacturer must be used. Used operating resources must be disposed of

correctly in accordance with applicable environment protection regulations.

Oil changes can be carried out by the manufacturer's customer service / oil

service organization.

On completion of checks and maintenance jobs, the procedures listed in "Restarting

the vehicle" must be carried out.

In unusual circumstances not described in this Operating Manual, please contact the

industrial truck manufacturer.

2

Safety regulations for industrial truck maintenance

Servicing and maintenance personnel:

Maintenance and repairs on all industrial

trucks and industrial truck systems may only be performed by qualified employees

authorized by the manufacturer, and must be carried out in accordance with the

procedures described in this chapter. Furthermore, maintenance and inspection must

be carried out in accordance with the recommendations of the manufacturer and

owner. The manufacturer's customer service organization has field engineers who

have been specially trained for this work. We recommend, therefore, that you take out

a maintenance agreement with the appropriate Customer Service Center.

The owner is responsible for ensuring that all procedures for the safe maintenance of

the equipment are followed. Completed maintenance work should be recorded in an

appropriate manner.

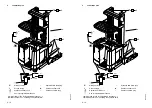

Lifting and jacking:

In order to lift the industrial truck, slinging equipment should only

be attached at the designated points. If the vehicle is jacked up, suitable means

(wedges, wooden blocks) must be used to prevent it from slipping or tipping. Work

under raised load-handling equipment is only permissible if the fork is immobilized

and secured by a chain of appropriate strength.

NOTICE

Jacking point see chapter D.

G 1

0

708

.USA

G Industrial truck maintenance

1

Operational safety and environmental protection

The checks and maintenance jobs set out in this chapter must be carried out at the

intervals specified in the maintenance checklists.

Q

wW

Operating an electric and manual industrial truck can be dangerous if

maintenance is neglected or if repairs, overhauls or settings are not carried

out in accordance with the manufacturer's instructions.

Q

wW

Any modification whatsoever to the industrial truck – and particularly to safety

devices – is prohibited. The operating speed of the industrial truck must not

be changed under any circumstances.

IMPORTANT

Only original spare parts are subject to our quality control. To ensure the safe

and reliable operation of the industrial truck, only spare parts from the

manufacturer must be used. Used operating resources must be disposed of

correctly in accordance with applicable environment protection regulations.

Oil changes can be carried out by the manufacturer's customer service / oil

service organization.

On completion of checks and maintenance jobs, the procedures listed in "Restarting

the vehicle" must be carried out.

In unusual circumstances not described in this Operating Manual, please contact the

industrial truck manufacturer.

2

Safety regulations for industrial truck maintenance

Servicing and maintenance personnel:

Maintenance and repairs on all industrial

trucks and industrial truck systems may only be performed by qualified employees

authorized by the manufacturer, and must be carried out in accordance with the

procedures described in this chapter. Furthermore, maintenance and inspection must

be carried out in accordance with the recommendations of the manufacturer and

owner. The manufacturer's customer service organization has field engineers who

have been specially trained for this work. We recommend, therefore, that you take out

a maintenance agreement with the appropriate Customer Service Center.

The owner is responsible for ensuring that all procedures for the safe maintenance of

the equipment are followed. Completed maintenance work should be recorded in an

appropriate manner.

Lifting and jacking:

In order to lift the industrial truck, slinging equipment should only

be attached at the designated points. If the vehicle is jacked up, suitable means

(wedges, wooden blocks) must be used to prevent it from slipping or tipping. Work

under raised load-handling equipment is only permissible if the fork is immobilized

and secured by a chain of appropriate strength.

NOTICE

Jacking point see chapter D.

Содержание ETR 314

Страница 1: ...Operating instructions 50 452 907 ETR 314 320 u 06 06 11 09 07 08 E Manual de instrucciones...

Страница 7: ...0608 USA I 4 0608 USA I 4...

Страница 9: ...0606 USA A 2 0606 USA A 2...

Страница 24: ...D 9 0107 USA D 9 0107 USA...

Страница 26: ...D 11 0107 USA D 11 0107 USA...

Страница 103: ...0107 USA F 10 0107 USA F 10...

Страница 123: ...0708 USA G 20 0708 USA G 20...

Страница 135: ...0608 E I 4 0608 E I 4...

Страница 137: ...0606 E A 2 0606 E A 2...

Страница 152: ...D 9 0107 E D 9 0107 E...

Страница 154: ...D 11 0107 E D 11 0107 E...

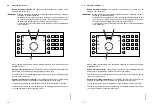

Страница 162: ...E 3 0608 E 1 2 18 17 4 5 3 6 7 8 9 10 11 12 13 14 15 16 E 3 0608 E 1 2 18 17 4 5 3 6 7 8 9 10 11 12 13 14 15 16...

Страница 164: ...E 5 0608 E 1 2 18 17 4 5 3 6 7 8 9 10 11 12 13 14 15 16 E 5 0608 E 1 2 18 17 4 5 3 6 7 8 9 10 11 12 13 14 15 16...

Страница 225: ...0608 E E 66 0608 E E 66...

Страница 235: ...0107 E F 10 0107 E F 10...

Страница 255: ...0708 E G 20 0708 E G 20...