16

– PREPARATIONS

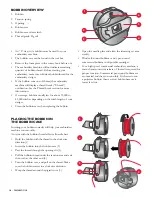

BOBBIN OVERVIEW

1. Bobbin

2. Tension spring

3. Opening

4. Bobbin case

5. Bobbin case release latch

6. Thread guide/Pig tail

• An “L” size/style bobbin must be used for your

embroidery machine.

• The bobbin case can be found in the tool box.

• Remove the foam piece in the rotary hook before use.

• The embroidery machine will not indicate remaining

quantity of bobbin thread. Before starting your

embroidery, make sure sufficient bobbin thread for the

embroidery design.

• If the bobbin runs out of thread, the embroidery

machine will display a thread break (“T-break”)

notification. See the Thread break section for more

information.

• On average, bobbins usually last for about 35,000 to

42,000 stitches depending on the stitch length of your

design.

• Clean the bobbin case when replacing the bobbin.

• Open the needle plate and clean the trimming set area

weekly.

• Wind self-wound bobbins or buy pre-wound

commercial bobbins in disposable cartridges.

• For a high speed, commercial embroidery machine, a

smooth and consistent release of thread is required for

proper function. Commercial pre-wound bobbins are

economical and they run smoothly. It is better to run

a polyester bobbin, than a cotton bobbin because it

leaves less lint.

PLACING THE BOBBIN IN

THE BOBBIN CASE

Inserting your bobbin correctly will help your embroidery

machine run smoothly.

An issue with the bobbin thread affects all needle bars.

• Hold the bobbin with the thread in the clockwise

direction (1).

• Insert the bobbin into the bobbin case (2).

• Pass the thread through the opening slit (3).

• Pull the bobbin thread under the tension arm and exit

the notch at the other end (4).

• Turn the bobbin over, and pull on the thread. Make

sure the bobbin rotates in a clockwise direction.

• Wrap the thread around the pigtail twice (5).

1

4

3

2

6

1

4

2

5

3

5