59

18. Startup & Running & Maintenance

a)

Preparing for first start up

Restarting after shutting down for long periods

The Heat pump must be started up for the first time by the Technical Service. Before starting up the Heat pumps,

make sure that:

-All safety conditions have been respected.

-The Heat pump system is adequately fixed to the surface it rests on.

-Functional distances have been respected.

-Hydraulic connections have been carried out as indicated in the manual.

-The water circuit is filled and vented. When draining after heat pump operation, take care as the water may be hot.

-The water circuit valves are open.

-Electrical connections have been carried out correctly.

-Voltage is within a tolerance of 10% of the rated voltage for the unit.

-The unit is correctly earthed.

-All electrical and hydraulic connections are tight and have been completed correctly.

b)Operating characteristics

Set point in cooling mode

(factory set) = 12°C, Hysteresis = 5°C.

The compressor starts with water temperatures above 12°C.

The compressor shuts down with water temperatures of less than 7°C.

Set point in heating mode

(factory set) = 45°C, Hysteresis = 5°C.

The compressor starts with water temperatures below 45°C.

The compressor shuts down with water temperatures above 50°C.

In the event of a temporary power failure, when power returns, the mode set previously will be retained in the

memory.

Compressor start up delay

Two functions prevent the compressor from starting up too frequently

- Minimum time since last start-up 300 seconds.

Pump

The electronic board includes a pump control output. The pump starts when the assembly is powered up and at

least 60 seconds before the compressor starts up and stops 60 seconds after the assembly shuts down. After the

first 60 seconds of pump operation when the water flow is at full speed, the water flow alarm functions are activated

(differential pressure switch and pressure difference switch). With a pump connected to terminals Pump on the

installer terminal board.

Содержание AU082FYCRA(HW)

Страница 1: ...ATW Service Manual SYJS 03 2019REV A Edition 2019 03 ...

Страница 11: ...9 405 410 600 174 174 450 950 965 395 6 Dimensions AU082FYCRA HW Unit mm ...

Страница 12: ...10 AU112 162FYCRA HW Unit mm 1490 950 380 187 405 410 600 174 174 450 170 ...

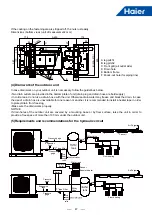

Страница 13: ...11 AU082FYCRA HW 7 Piping Diagram ...

Страница 14: ...12 AU112 162FYCRA HW ...

Страница 27: ...25 12 Water Pressure Drop ...

Страница 28: ...26 ...

Страница 57: ...55 15 PCB Photo BM2 BM1 PCB code 0151800423 ...