40

Precautions for Handling Units for Use with R32

CAUTION

Do not use the existing refrigerant piping

•

The old refrigerant and refrigerator oil in the existing

piping contain a large amount of chlorine, which will

cause the refrigerator oil in the new unit to deteriorate.

• R32 is a high-pressure refrigerant, and the use of the

existing piping may result in bursting.

Use a vacuum pump with a reverse-flow check valve.

• If other types of valves are used, the vacuum pump

oil will flow back into the refrigerant cycle and

cause the refrigerator oil to deteriorate.

Keep the inner and outer surfaces of the pipes clean

and free of contaminants such as sulfur, oxides, dust/dirt

shaving particles,oils,and moisture.

•

Contaminants inside the refrigerant piping will cause the

refrigerant oil to deteriorate.

Do not use the following tools that have been used

with the conventional refrigerants. Prepare tools that

are for exclusive use with R32.

(Gauge manifold, charging hose, gas leak detector,

reverse-flow check valve, refrigerant charge

base,vacuum gauge, and refrigerant recovery

equipment.)

•

If refrigerant and/or refrigerant oil left on these tools

are mixed in with R32, or if water is mixed with

R32, it will cause the refrigerant to deteriorate.

• Since R32 does not contain chlorine, gas-leak

detectors for conventional refrigerators will not

work.

Store the piping to be used during installation indoors,

and keep both ends of the piping sealed until immediately

before brazing.(keep elbows and other joints wrapped in

plastic.)

• If dust, dirt, or water enters the refrigerant cycle, it may

cause the oil in the unit to deteriorate or may cause the

compressor to malfunction.

Do not use a charging cylinder.

•

The use of charging cylinder will change the

composition of the refrigerant and lead to power

loss.

Use a small amount of ester oil, ether oil, or alkylbenzene

to coat flares and flange connections.

•

A large amount of mineral oil will cause the refrigerating

machine oil to deteriorate.

Exercise special care when handling the tools.

• An introduction of foreign objects such as dust, dirt

or water into the refrigerant cycle will cause the

refrigerating machine oil to deteriorate.

Use liquid refrigerant to charge the system.

•

Charge the unit with gas refrigerant will cause the

refrigerant in the cylinder to change its composition and

will lead to a drop in performance

Only use R32 refrigerant.

•

The use of refrigerants containing chlorine(i.e.

R22) will cause the refrigerant to deteriorate.

CAUTION

Do not install the unit in a place where there is a possibility

of flammable gas leak.

• Leaked gas accumulated around the unit may start a fire

or explosion.

When installing the unit in a hospital, take necessary

measures against noise.

• High-frequency medical equipment may interfere

with the normal operation of the air conditioning

unit or the air conditioning unit may interfere with

the normal operation of the medical equipment

Do not use the unit to preserve food, animals, plants,

artifacts, or for other special purposes.

•

The unit is not designed to provide adepuate conditions

to preserve the quality of these items.

Do not place the unit on or over things that may not

get wet.

•

When humidity level exceeds 80% or when the

drainage system is clogged, indoor units may drip

water.

•

Installation of a centralized drainage system for

the outdoor unit may also need to be considered to

prevent water drips from the outdoor units.

Do not use the unit in an unusual environment

•

The use of the unit in the presence of a large amount

of oil, steam, acid, alkaline solvents or special types of

sprays may lead to a remarkable drop in performance

and/or malfunction and presents a risk of electric shock,

smoke, fire, or explosion.

• The presence of organic solvents, corroded gas (such as

ammonia,sulfur compounds,and acid may cause gas or

water leak.)

Before Installing the Unit

Содержание AU082FYCRA(HW)

Страница 1: ...ATW Service Manual SYJS 03 2019REV A Edition 2019 03 ...

Страница 11: ...9 405 410 600 174 174 450 950 965 395 6 Dimensions AU082FYCRA HW Unit mm ...

Страница 12: ...10 AU112 162FYCRA HW Unit mm 1490 950 380 187 405 410 600 174 174 450 170 ...

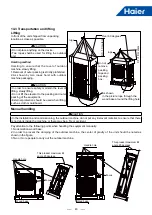

Страница 13: ...11 AU082FYCRA HW 7 Piping Diagram ...

Страница 14: ...12 AU112 162FYCRA HW ...

Страница 27: ...25 12 Water Pressure Drop ...

Страница 28: ...26 ...

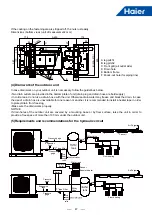

Страница 57: ...55 15 PCB Photo BM2 BM1 PCB code 0151800423 ...