No infeed above CCT

Specifies the combustion chamber temperature, from

which fuel feed is stopped, to bring the combustion

chamber temperature back down below this value. The

parameter functions as a direct switch threshold for

stopping infeed and is a safety function to prevent the

combustion chamber from overheating.

Start power reduction from CCT signal

Specifies the start point for infeed reduction as a

percentage of the combustion chamber temperature

control band. The control band is defined by the

parameters "0% CCT signal at CCT" and "100% CCT

signal at CCT". If the combustion chamber temperature is

too high, infeed and primary air are reduced to the

minimum infeed from this value. The parameter is only

effective, if there is no FGR or it is inactive. In FGR mode

the FGR system reduces the infeed when the combustion

chamber temperatures are too high.

Start secondary air cooling at CCT signal

Specifies the start point for secondary air cooling as a

percentage of the combustion chamber temperature

control band. The control band is defined by the

parameters "0% CCT signal at CCT" and "100% CCT

signal at CCT". If the combustion chamber temperature is

too high, the secondary air is opened from this value. For

the start of cooling you should ensure that the secondary

air does not begin at 0, but at the current (oxygen

managed) secondary air setting.

End secondary air cooling at CCT signal

Specifies the end point for secondary air cooling as a

percentage of the combustion chamber temperature

control band. The control band is defined by the

parameters "0% CCT signal at CCT" and "100% CCT

signal at CCT". At this percentage the secondary air flap

has reached the maximum permitted opening (100%). 100

percent stop point corresponds to the maximum

combustion chamber temperature.

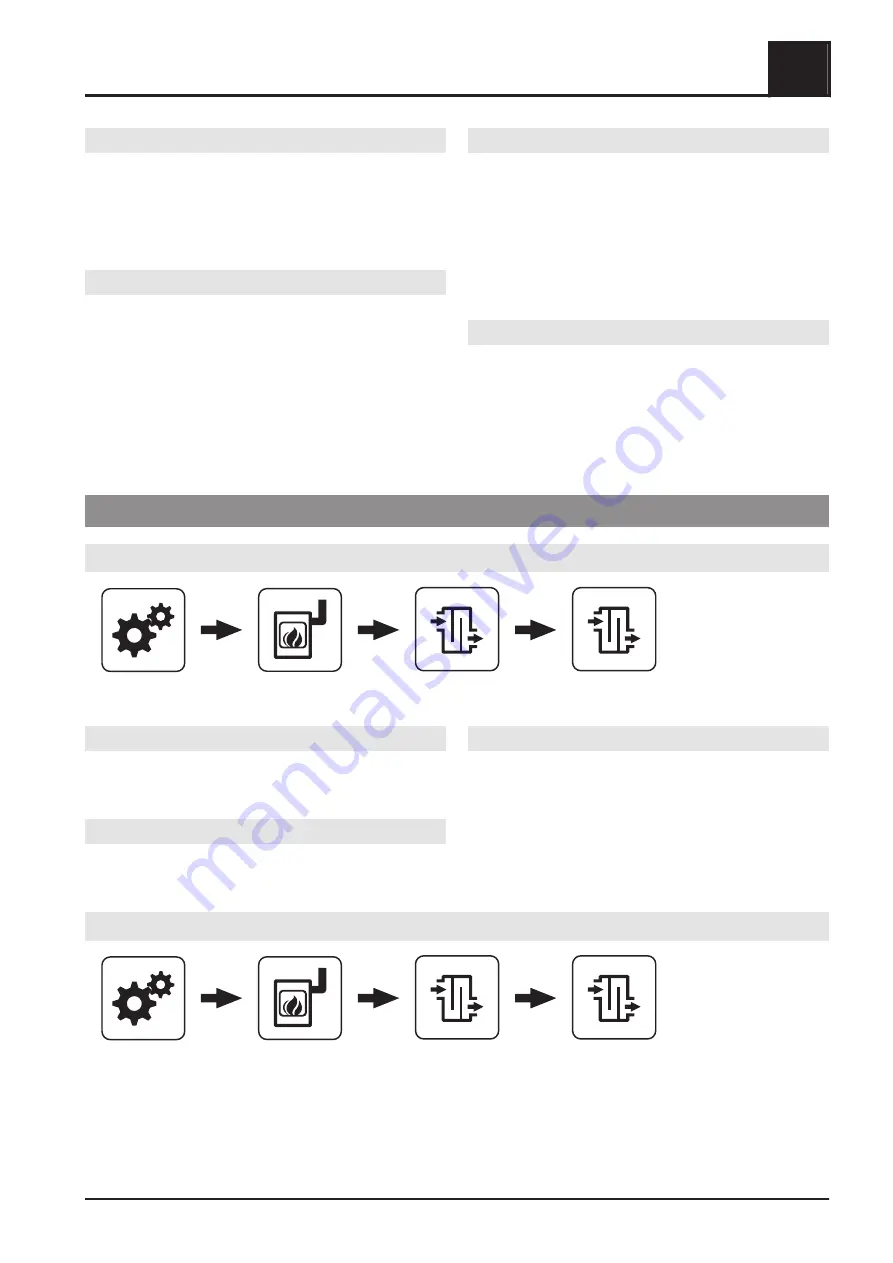

5.3.10 Heat exchanger

Heat exchanger configuration

System menu

Boiler

Heat exchanger

Heat exchanger configuration

Heat exchanger cleaning interval

Specifies how long the feed screw must feed until the

WOS drive is activated (“heat exchanger cleaning runtime"

parameter).

Heat exchanger cleaning runtime

Specifies the runtime of the WOS drive within the set time

window (“heat exchanger cleaning activated from" and

“heat exchanger cleaning activated until” parameter).

WOS speed, manual

WOS drive speed for use with the speed monitor

Manual heat exchanger

System menu

Boiler

Heat exchanger

Manual heat exchanger

The menu is used to test and calibrate the WOS. The calibration is only possible if the corresponding inputs and

outputs are configured.

⇨ See "Perform hardware detection manually" [page 24]

Menus and parameters

5

Boiler

Service manual SPS 4000 | B0960622_en

51

Содержание SPS 4000

Страница 114: ...7 Electric components and wiring PLC 114 Fröling GesmbH A 4710 Grieskirchen Industriestraße 12 www froeling com ...

Страница 142: ...8 Notes 8 Notes 142 Fröling GesmbH A 4710 Grieskirchen Industriestraße 12 www froeling com ...

Страница 143: ...Notes 8 Service manual SPS 4000 B0960622_en 143 ...