Hydraulic bunker cover

Specifies the number of hydraulic bunker covers.

External control

Specifies the number of externally controlled discharges.

Discharge / configurations

System menu

System

configuration

Fuel

feed

Discharge /

configuration

Menu for configuring the individual components of the discharge system and for setting the sequence. The

entries in this menu depend on the settings in the “Feeder unit” and “Chamber discharge system” menus.

... is loaded by

Specifies the feeder unit from which the selected

component is loaded.

Safety group...

Assigns the relevant component to a safety group. The

setting must be carried out according to the wiring or

electrical diagram.

... permanently active

If this parameter is activated, this conveyor always

conveys the material to the material transport, even if the

boiler does not request any material. The parameter is

then used when two material consumers (e.g. multi-boiler

systems) should be filled even when the system is

switched off.

It is recommended that the sequence always be carried out from the lock to the discharge system. This normally

corresponds to the wiring in the circuit diagram and the order of the menu entries from top to bottom. It should

be noted that a screw of the chamber discharge system must also be parameterised as a feed screw.

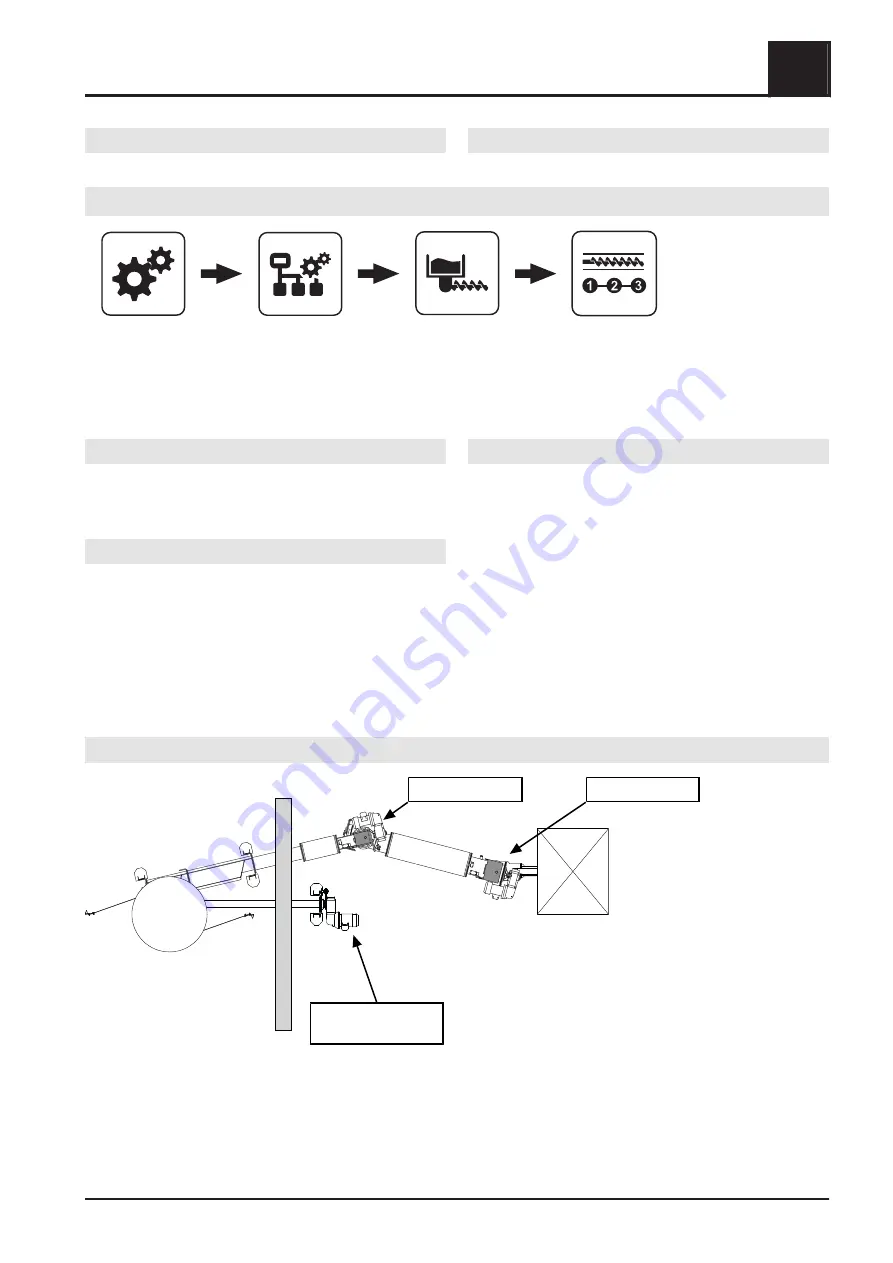

Example 1 - rotary agitator with separate drive and two feed screws

Rotary agitator

separately driven

Feed screw 1

Feed screw 2

Menus and parameters

5

System configuration

Service manual SPS 4000 | B0960622_en

81

Содержание SPS 4000

Страница 114: ...7 Electric components and wiring PLC 114 Fröling GesmbH A 4710 Grieskirchen Industriestraße 12 www froeling com ...

Страница 142: ...8 Notes 8 Notes 142 Fröling GesmbH A 4710 Grieskirchen Industriestraße 12 www froeling com ...

Страница 143: ...Notes 8 Service manual SPS 4000 B0960622_en 143 ...