Delay error overfilling rotary valve

The time by which an error message is delayed when the

overflow sensor of the rotary valve activates.

Maximum empty stoker time

If it is not clear during this time that the stoker is empty, an

error is issued.

5.4.4 Conveyor

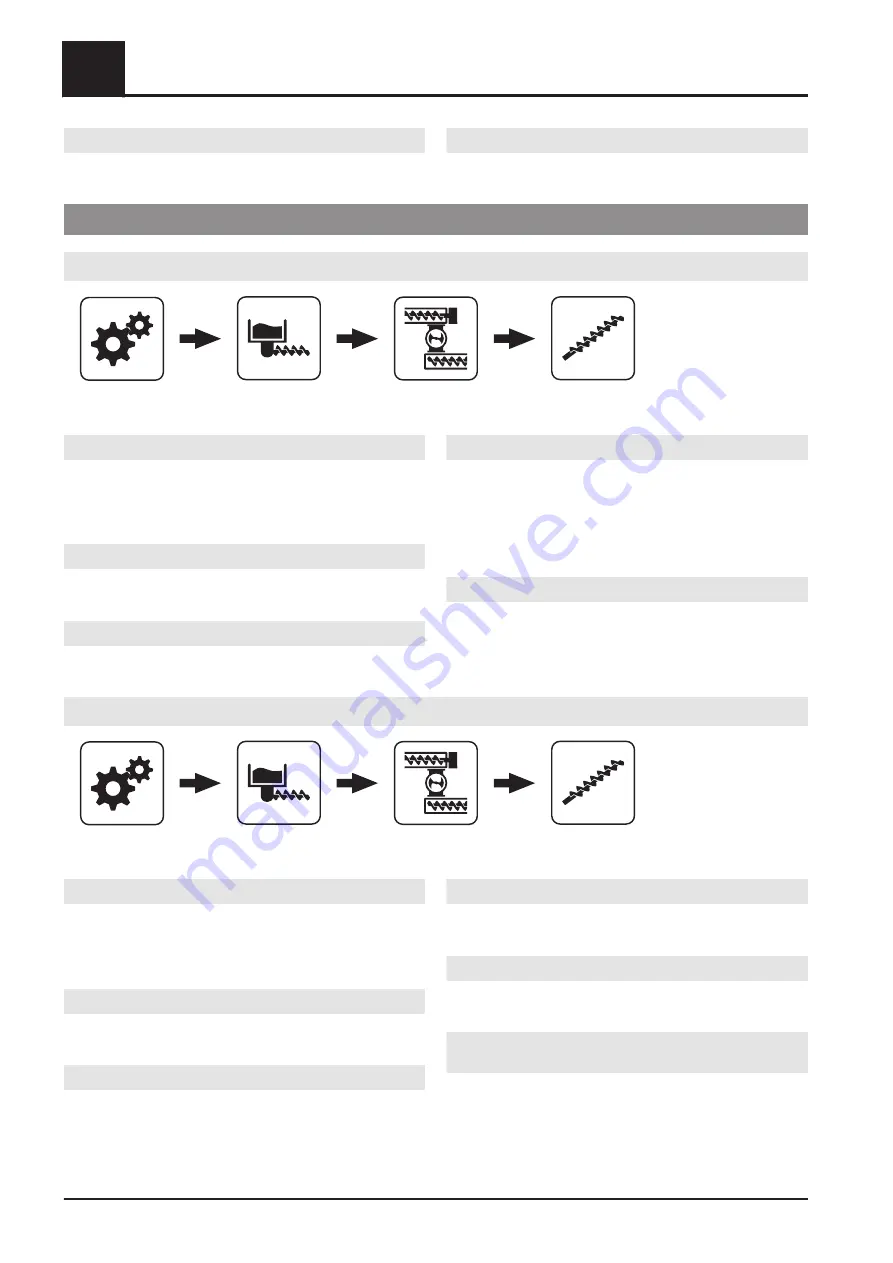

Feed screw 1... 6

System menu

Fuel

feed

Conveyor

Feed screw

Startup delay of feed screw

If the level sensor in the gravity shaft detects no material

during this time, the feed screw is started. This parameter

is used for controlling the material transport and does not

refer to the runtimes of other components.

Shutdown delay of feed screw

If the light barrier is occupied, the feed screw is switched

off with a delay of the set value.

Max. runtime feed screw

If the light barrier detects no material within the set time,

the system is switched off.

Runtime of next screw until automatic run of feed screw

If the screw following the feed screw (in the direction of the

material flow) runs for the set time without the light barrier

of the feed screw indicating empty, the automatic runtime

is activated on the feed screw. This causes any jammed

material in the area of the light barrier of the feed screw to

loosen again.

Automatic run of feed screw

Runtime of the feed screw in automatic runtime.

Cross conveyor screw 1...3

System menu

Fuel

feed

Conveyor

Cross conveyor screw

Cross conveyor screw startup delay

If the level sensor in the gravity shaft detects no material

during this time, the cross conveyor screw is started. This

parameter is used for controlling the material transport and

does not refer to the runtimes of other components.

Cross conveyor screw shutdown delay

If the light barrier is occupied, the cross conveyor screw is

switched off with a delay of the set value.

Cross conveyor screw startup delay demand

If the level sensor does not detect any material within this

time, the cross conveyor screw requests material.

Cross conveyor screw shutdown delay demand

If the light barrier is occupied, the cross conveyor screw

delays the request for material by the set value.

Max. runtime cross conveyor screw

If the light barrier detects no material within the set time,

the system is switched off.

Runtime of next screw until automatic run of cross

conveyor screw

If the screw following cross conveyor screw 1 (in the

direction of the material flow) runs for the set time without

the light barrier of cross conveyor screw 1 indicating

empty, the automatic runtime is activated on cross

conveyor screw 1. This causes any jammed material in the

area of the light barrier of cross conveyor screw 1 to

loosen again.

5

Menus and parameters

Fuel feed

58

Fröling GesmbH | A-4710 Grieskirchen, Industriestraße 12 | www.froeling.com

Содержание SPS 4000

Страница 114: ...7 Electric components and wiring PLC 114 Fröling GesmbH A 4710 Grieskirchen Industriestraße 12 www froeling com ...

Страница 142: ...8 Notes 8 Notes 142 Fröling GesmbH A 4710 Grieskirchen Industriestraße 12 www froeling com ...

Страница 143: ...Notes 8 Service manual SPS 4000 B0960622_en 143 ...