MACHINE TRANSPORT AND STORAGE

SECTION 3

Page 9

DRESSTA

OM515C520C99/1E

MACHINE STORAGE

20. It is recommended to pour 50 [ml] VCI type 1 oil per HMS B00-0006 Standard to the hydraulic

reservoir.

21. Remove the batteries and place them on wooden skids. Then store them in a cool, clean,

dry, well-ventilated place away from areas provided for storing or dispensing fuel and oil, not

near any heat source and preferably where the temperature range is between 0 [

°

C] to +21

[

°

C] . Be sure the batteries are fully charged.

IMPORTANT:

Do not place battery on a concrete floor or in temperature below 0 [

°°

C].

IMPORTANT:

If the machine is stored with dry charged batteries or no batteries, the alternator

output lead (+) must be disconnected and insulated. Failure to do so may result in permanent

damage to the alternator.

22. If the bucket is detached for storage, secure the cylinder piston rod to the machine to avoid

damage.

23. Coat all machined and unpainted surfaces with chassis grease to prevent rust. It is

recommended to use AKORIN N-2 grease.

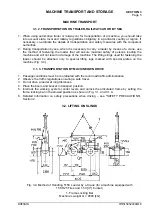

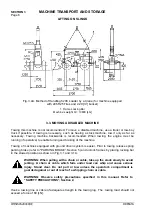

24. If it is desirable to leave the tires on the machine, jack the machine up and place it on blocks

leaving the tires in suspension. Deflate and cover the tires. Tires should not be exposed to

direct sunlight or any fuel or solvent vapors.

WARNING: Use extra caution when jacking up the machine. Jacking up the

machine can be hazardous if performed improperly. Use jacking equipment of

sufficient capacity. Be sure the jacking points are strong enough to support the

machine. Be sure the jack is stable and well supported. Before jacking up the

machine, block the tires which will not be lifted. Lock the frame halves together

with the locking bar and pins. If the rear tires are being lifted, block the rear axle

to prevent it from pivoting unexpectedly. DO NOT run the engine with the

machine on jacks.

3.4.2. SERVICING DURING STORAGE

ONE-MONTH REPETITIVE SERVICE PERIOD

Be sure the batteries are fully charged. Never allow batteries to run down below 3/4 full charge.

WARNING: DO NOT charge batteries in a closed area. Provide proper ventilation

to guard against explosion of an accumulation of the gas given off in the

charging process.

SIX-MONTH REPETITIVE SERVICE PERIOD

1. Visually inspect the engine and radiator for leakage and other defects. Correct all defects,

consult Authorized Construction Equipment Distributor if necessary.

2. Remove all seals from the machine ports: crank-case and hydraulic breather plugs, engine air

intake, fuel tank vent lines, etc.

3. Install fully charged batteries. Refer to "BATTERIES", Section 5.

WARNING: Be sure the electrical system master switch is off when connecting or

disconnecting batteries to minimize the chance of sparks and explosion.

Содержание 515C

Страница 3: ...OM515C520C99 1E DRESSTA ...

Страница 5: ......

Страница 7: ......

Страница 10: ...SECTION 1 INTRODUCTION ...

Страница 11: ...INTRODUCTION SECTION 1 DRESSTA OM515C520C99 1E SECTION CONTENTS 1 1 Introduction 3 1 2 Serial Numbers 5 ...

Страница 12: ......

Страница 17: ...SECTION 2 SAFETY PRECAUTIONS ...

Страница 19: ......

Страница 37: ...SECTION 3 MACHINE TRANSPORT AND STORAGE ...

Страница 39: ......

Страница 49: ...SECTION 4 OPERATING ...

Страница 51: ......

Страница 55: ...SECTION 4 OPERATING Page 6 OM515C520C99 1E DRESSTA UNIVERSAL SYMBOLS FOR INSTRUMENTS AND CONTROLS ...

Страница 107: ...SECTION 5 MAINTENANCE ...

Страница 165: ...SECTION 6 SPECIFICATIONS ...

Страница 167: ......

Страница 181: ...SECTION 6 SPECIFICATIONS Page 16 OM515C520C99 1E DRESSTA WIRING DIAGRAMS ...

Страница 182: ...SPECIFICATIONS SECTION 6 Page 17 DRESSTA OM515C520C99 1E WIRING DIAGRAMS ...

Страница 187: ...SECTION 6 SPECIFICATIONS Page 22 OM515C520C99 1E DRESSTA WIRING DIAGRAMS ...

Страница 192: ...SPECIFICATIONS SECTION 6 Page 27 DRESSTA OM515C520C99 1E SPECIFICATIONS Fig 6 10A Overall Dimensions Wheel Loader 520C ...