SECTION 4

OPERATING

Page 36

OM515C520C99/1E

DRESSTA

LOADER OPERATIONS

FLOAT (UPGRADED VERSION)

When the float switch is on (Fig. 4.8), the boom will gradually lower. This position is locked with

a spring. To shift back to "hold" the switch must be put off. Use the “float" position to follow the

contour of the ground when backdragging or leveling hard ground.

WARNING! It is forbidden to lower the boom from fully raised position by moving

the control lever to “float" position. Due to weight of loader linkage it may be

dangerous for nearby personnel and damaging to the machine.

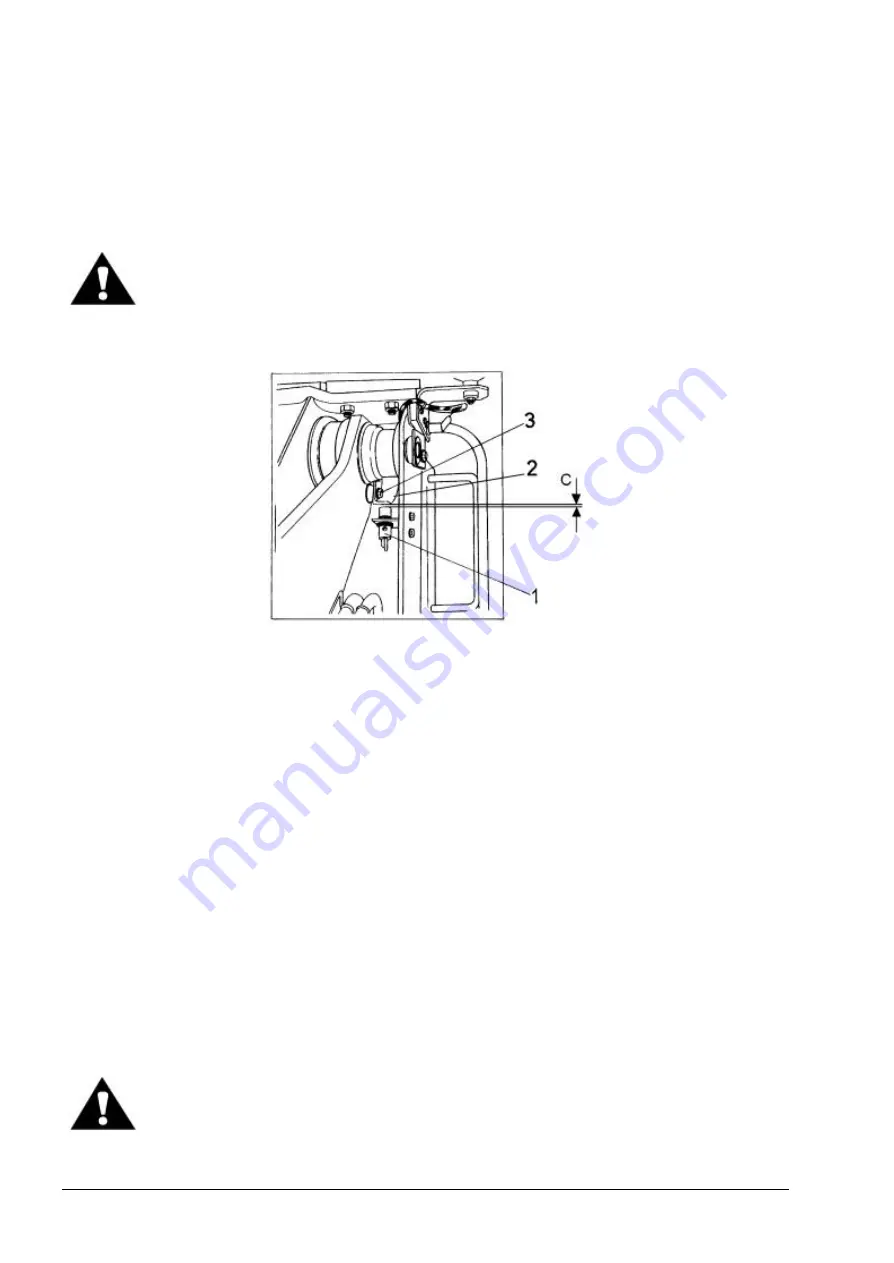

4.17.2. AUTOMATIC BOOM KICK-OUT (Fig. 4.30.)

Fig. 4.30. Automatic Boom Kick Out

1. Proximity Switch

2. Adjustment Plate

3. Locking Bolt

C. Plate-to-Switch Clearance

The electronically operated kick-out control system stops boom travel automatically at a

preselected height. This eliminates unnecessary boom travel during operation and provides for a

more efficient cycle.

Adjustment plate (2) is bolted to the left boom arm and is adjustable. Proximity switch (1) is

mounted to the front frame. Proximity switch (1) creates a magnetic field circuit which is completed

by the proximity of adjustment plate (2) within the magnetic field. Once the boom is raised to its

preselected height, adjustment plate (2) has moved out of the magnetic field, breaking the circuit.

Breaking the magnetic field circuit causes the boom control lever to move out of the detented

"RAISE" position and into the "HOLD" position, thereby stopping the travel of the boom arms. Plate-

to-switch clearance "C" necessary for the proper operation of the proximity switch is 7 to 8 [mm].

ADJUSTMENT OF AUTOMATIC BOOM KICK-OUT

To change the automatic boom kick-out position, raise the boom arms to the desired stopping

height. Place the boom control lever in the "HOLD" position. Loosen locking bolt (3) on sensor plate

(2). Move adjustment plate (2) until it is just out of the magnetic field of proximity switch (1). Tighten

locking bolt (3) on adjustment plate (2). Start the machine and test the adjustment. Repeat this

procedure until the automatic kick-out height is obtained.

WARNING! Use extra caution when adjusting loader’s bucket leveler or boom

kick-out. Use two trained people and guard against accidental movement of the

machine or loader linkage. No personnel is allowed within the reach of loader

linkage. Never work or walk under raised bucket without proper blocking.

Содержание 515C

Страница 3: ...OM515C520C99 1E DRESSTA ...

Страница 5: ......

Страница 7: ......

Страница 10: ...SECTION 1 INTRODUCTION ...

Страница 11: ...INTRODUCTION SECTION 1 DRESSTA OM515C520C99 1E SECTION CONTENTS 1 1 Introduction 3 1 2 Serial Numbers 5 ...

Страница 12: ......

Страница 17: ...SECTION 2 SAFETY PRECAUTIONS ...

Страница 19: ......

Страница 37: ...SECTION 3 MACHINE TRANSPORT AND STORAGE ...

Страница 39: ......

Страница 49: ...SECTION 4 OPERATING ...

Страница 51: ......

Страница 55: ...SECTION 4 OPERATING Page 6 OM515C520C99 1E DRESSTA UNIVERSAL SYMBOLS FOR INSTRUMENTS AND CONTROLS ...

Страница 107: ...SECTION 5 MAINTENANCE ...

Страница 165: ...SECTION 6 SPECIFICATIONS ...

Страница 167: ......

Страница 181: ...SECTION 6 SPECIFICATIONS Page 16 OM515C520C99 1E DRESSTA WIRING DIAGRAMS ...

Страница 182: ...SPECIFICATIONS SECTION 6 Page 17 DRESSTA OM515C520C99 1E WIRING DIAGRAMS ...

Страница 187: ...SECTION 6 SPECIFICATIONS Page 22 OM515C520C99 1E DRESSTA WIRING DIAGRAMS ...

Страница 192: ...SPECIFICATIONS SECTION 6 Page 27 DRESSTA OM515C520C99 1E SPECIFICATIONS Fig 6 10A Overall Dimensions Wheel Loader 520C ...