SECTION 5

MAINTENANCE

Page 4

OM515C520C99/1E

DRESSTA

5.2. SCHEDULED MAINTENANCE GUIDE

Every 10 Hours of Operation (daily maintenance)

1. Perform the ground level inspection. Refer to 5.2.1.

2. Check the hydraulic tank oil level and add oil if necessary. Refer to 5.14.1.

3. Check the transmission oil level and add oil if necessary. Refer to 5.18.1.

4. Check the coolant level in the radiator. Refer to 5.8.4.

5. Check the engine oil level. Refer to 5.11.1.

6. Check the brake fluid level in the master cylinder housing. Refer to 5.7.2.

7. Visually check the condition of the fan blades and fan drive belt. Refer to 5.11.3 and 5.11.4.

8. Check the tires for cracks, cuts delamination, check the air pressure (inflate if necessary).

Refer to 5.17.

9. Check and clean the precleaner screen, if necessary. Refer to 5.6.4.

10. Check the service indicator and perform service if the filter contamination is signaled by the

indicator. Refer to 5.6.2 and 5.6.3.

11. Drain water and sediment from the fuel tank. Refer to 5.13.1.

12. Drain water and sediment from the fuel filter water separator. Refer to 5.13.3.

13. Refill the fuel tank at the end of each day's operation. Refer to 5.13.1.

Every 50 Hours of Operation

1. Perform the service as specified in "Every 10 hours of operation"

2. Air clean the radiator core. Refer to 5.8.8.

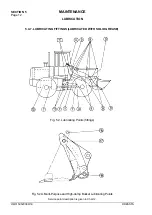

3. Lubricate:

−

the drive shafts splines and pivots,

−

rear axle bolster pivots,

−

cylinder pivots (steering, boom, bucket),

−

center articulation pivots,

−

transfer drive bearings,

−

the boom and bucket pivots,

Refer to 5.4.7.

4*

)

Clean transmission system suction strainer. Refer to 5.18.4.

5*

)

Replace transmission system pressure filter element. Refer to 5.18.3.

6*

)

Replace hydraulic system return filter element. Refer to 5.14.3.

.

*) after initial 50 hours of operation only

Every 250 Hours of Operation or 6 Months

1. Perform the service as specified in "Every 50 hours of operation".

2. Check the air intake system for loose clamps, the condition of hoses and tubes. Refer to 5.6.6.

3. Check the wheel mounting hardware for torque. Refer to 5.17.

4. Check the operation of the parking brake. Refer to 5.7.5.

5. Check the drive axles (differential and planetaries) oil level. Refer to 5.9.1.

6. Change the engine crankcase oil and engine oil filter. Refer to 5.11.2.

Содержание 515C

Страница 3: ...OM515C520C99 1E DRESSTA ...

Страница 5: ......

Страница 7: ......

Страница 10: ...SECTION 1 INTRODUCTION ...

Страница 11: ...INTRODUCTION SECTION 1 DRESSTA OM515C520C99 1E SECTION CONTENTS 1 1 Introduction 3 1 2 Serial Numbers 5 ...

Страница 12: ......

Страница 17: ...SECTION 2 SAFETY PRECAUTIONS ...

Страница 19: ......

Страница 37: ...SECTION 3 MACHINE TRANSPORT AND STORAGE ...

Страница 39: ......

Страница 49: ...SECTION 4 OPERATING ...

Страница 51: ......

Страница 55: ...SECTION 4 OPERATING Page 6 OM515C520C99 1E DRESSTA UNIVERSAL SYMBOLS FOR INSTRUMENTS AND CONTROLS ...

Страница 107: ...SECTION 5 MAINTENANCE ...

Страница 165: ...SECTION 6 SPECIFICATIONS ...

Страница 167: ......

Страница 181: ...SECTION 6 SPECIFICATIONS Page 16 OM515C520C99 1E DRESSTA WIRING DIAGRAMS ...

Страница 182: ...SPECIFICATIONS SECTION 6 Page 17 DRESSTA OM515C520C99 1E WIRING DIAGRAMS ...

Страница 187: ...SECTION 6 SPECIFICATIONS Page 22 OM515C520C99 1E DRESSTA WIRING DIAGRAMS ...

Страница 192: ...SPECIFICATIONS SECTION 6 Page 27 DRESSTA OM515C520C99 1E SPECIFICATIONS Fig 6 10A Overall Dimensions Wheel Loader 520C ...