MAINTENANCE

SECTION 5

Page 23

DRESSTA

OM515C520C99/1E

COOLING SYSTEM

5.8.2. ANTIFREEZE

Low silicate ethylene glycol antifreeze is recommended. The antifreeze should contain no more that

0.1% anhydrous alkali metasilicate. Low silicate antifreeze is recommended to avoid the formation

of silica-gel (hydro-gel). This gel formation can occur when the cooling system contains an over

concentration of high silicate antifreeze and/or supplemental coolant additive. DO NOT use

methanol or alcohol as an antifreeze because of its low boiling point. Antifreeze may retain its

freeze protection for more than one season but coolant conditioners must be added to maintain

corrosion protection. Antifreeze formulated with metoxy propanol, or propylene glycol is not

recommended for this system.

IMPORTANT!

Do not mix types of antifreeze solutions. Mixed solutions make it impossible to

determine the protection against freezing. Antifreeze containing sealer or anti-leak additives

should not be used in this system. Sealer or anti- leak additives will plug the coolant filter and

cause plugging problems in the cooling system.

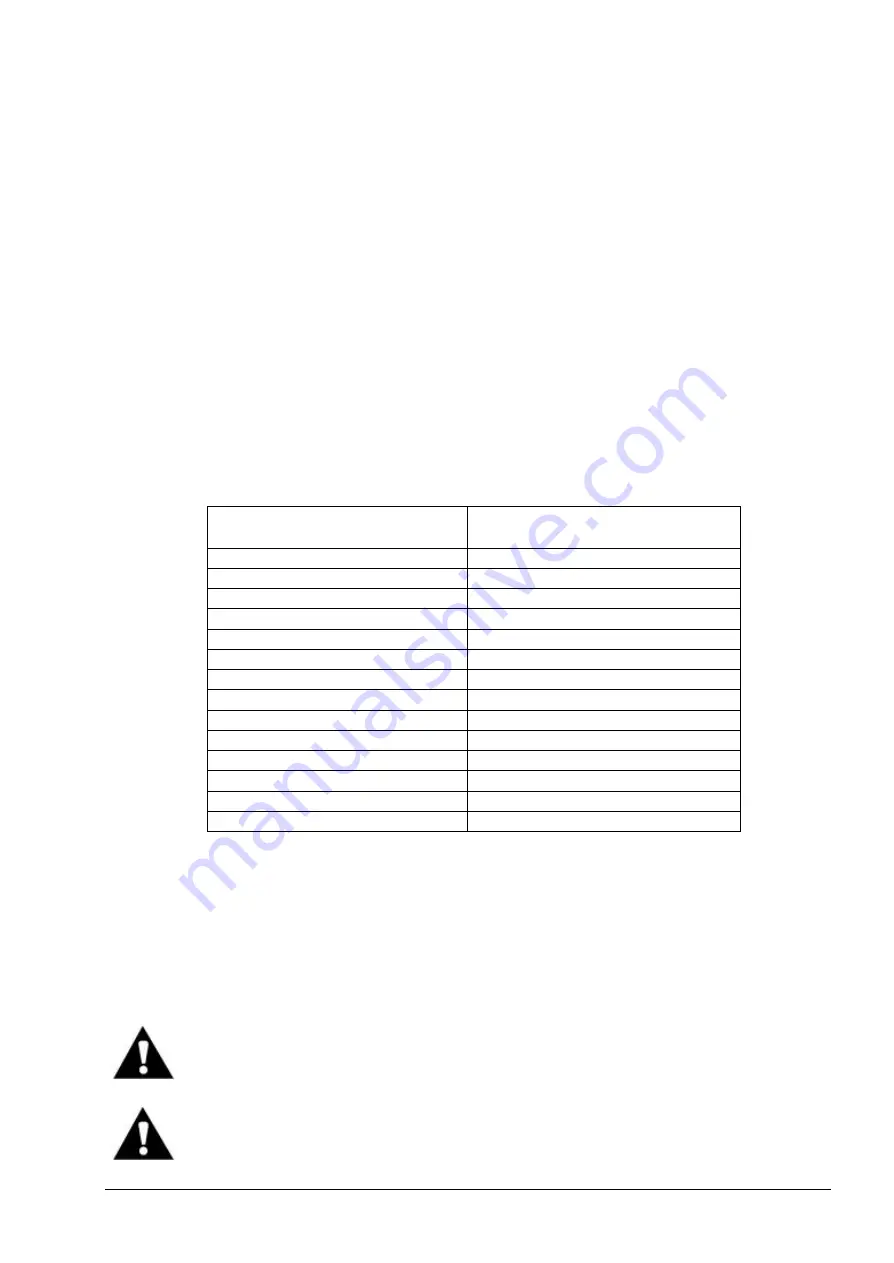

Chart 4 below shows percentage of antifreeze concentration required for various temperatures.

Approximate Freezing Point in

[ºC]

Percentage of Antifreeze

Concentration by Volume

0

0

- 7

15

-12

25

- 18

33

- 23

40

- 29

45

- 34

48

- 40

53

- 46

56

- 51

59

- 57

62

- 62

65

- 68

67

- 69

68

5.8.3. RADIATOR CAP (Fig. 5.9)

The radiator cap seals the coolant filler opening in the top tank of the radiator. Positive sealing

requires a cap gasket and contacting surfaces to be in good condition and a properly tightened cap.

The radiator cap incorporates a pressure relief valve. The pressure relief valve maintains the

pressure of the cooling system. When the preset pressure is exceeded the excess of the steam is

released to the atmosphere thru an overflow tube routed under the radiator.

WARNING! Never remove radiator cap if engine is hot. Wait until the

temperature drops below 50 [

°°

C]. Failure to meet this recommendation may

result in personal injury with hot coolant or steam.

WARNING! Hot, scalding coolant can spray out if the radiator cap is removed

suddenly. Relieve system pressure by slowly turning the cap to the first notch or

lifting the safety lever (if equipped). Remove the cap only after the pressure is

relieved.

Содержание 515C

Страница 3: ...OM515C520C99 1E DRESSTA ...

Страница 5: ......

Страница 7: ......

Страница 10: ...SECTION 1 INTRODUCTION ...

Страница 11: ...INTRODUCTION SECTION 1 DRESSTA OM515C520C99 1E SECTION CONTENTS 1 1 Introduction 3 1 2 Serial Numbers 5 ...

Страница 12: ......

Страница 17: ...SECTION 2 SAFETY PRECAUTIONS ...

Страница 19: ......

Страница 37: ...SECTION 3 MACHINE TRANSPORT AND STORAGE ...

Страница 39: ......

Страница 49: ...SECTION 4 OPERATING ...

Страница 51: ......

Страница 55: ...SECTION 4 OPERATING Page 6 OM515C520C99 1E DRESSTA UNIVERSAL SYMBOLS FOR INSTRUMENTS AND CONTROLS ...

Страница 107: ...SECTION 5 MAINTENANCE ...

Страница 165: ...SECTION 6 SPECIFICATIONS ...

Страница 167: ......

Страница 181: ...SECTION 6 SPECIFICATIONS Page 16 OM515C520C99 1E DRESSTA WIRING DIAGRAMS ...

Страница 182: ...SPECIFICATIONS SECTION 6 Page 17 DRESSTA OM515C520C99 1E WIRING DIAGRAMS ...

Страница 187: ...SECTION 6 SPECIFICATIONS Page 22 OM515C520C99 1E DRESSTA WIRING DIAGRAMS ...

Страница 192: ...SPECIFICATIONS SECTION 6 Page 27 DRESSTA OM515C520C99 1E SPECIFICATIONS Fig 6 10A Overall Dimensions Wheel Loader 520C ...