Maintenance of Major Components

- 168 -

4) Measuring tension

(1) Lower indicator arm (1) into the scale.

Apply tester to belt at a point

midway between two pulleys so

that edge of contact surface (2) is

flush with the V- belt.

Slowly depress pad (3) until the

spring can be heard to disengage.

This will cause the indicator to

move upwards.

If pressure is maintained after the

spring has disengaged a false

reading will be obtained!

(2) Reading of tension

Read of the tensioning force of the

belt at the point where the top

surface of the indicator arm (1)

intersects with the scale.

Before taking readings make ensure

that the indicator arm remains in its

position.

V-belt tension

Poly belt tension

(1)

EA6O6011

(3)

(2)

EA6O6012

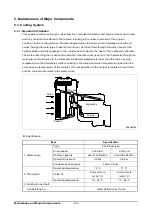

Type

Drive belt width

Tensioning forces on the tester

new installation

When servicing after

long runing time

Installation

After 10 min.

running time

M

9.5 mm

50 kg

45 kg

40 kg

A

11.8 mm

55 kg

50 kg

45 kg

B

15.5 mm

75 kg

70 kg

60 kg

C

20.2 mm

75 kg

70 kg

60 kg

ED4OM044

No of rib(Rubber)

Oil and heat resistant insulation

Stretch resistant tension member

Oil and abrasion resistant backing

No of rib (PK type) Force(kgf)

3

20 - 27

4

27 - 36

5

34 - 45

6

41 - 57

7

48 - 66

8

59 - 73

Содержание GL08K

Страница 1: ...950106 050004EN GL08K GAS VEHICLE ENGINE Operation Maintenance Manual ...

Страница 2: ......

Страница 4: ......

Страница 6: ......

Страница 151: ...Maintenance 145 7 Vehicle wiring harness EH3M5012 Truck engine Bus engine ...

Страница 193: ...Appendix 187 Engine Assembly Bus EJ3OM012 ...

Страница 194: ...Appendix 188 Engine Assembly Truck EJ3OM013 ...

Страница 195: ...Special Tool List 950106 080002 ...

Страница 196: ......