Maintenance

- 82 -

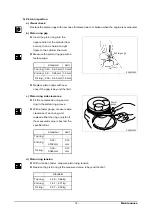

Install the bearing cap by matching the

cylinder block No. with the bearing cap No.

Apply oil to the entire part of the bearing

cap bolts, then tighten in tightening

sequence to specified torque.

After semi-tightening both bolts evenly,

tighten them diagonally to the specified

torque using a torque wrench as follows.

<Tightening order>

(1) First stage

: Coat the cap bolts with engine oil

(2) Second stage : Temporary bolt screwing about 1 ~ 2 threads

(3) Third stage

: With impact wrench, tighten up to about 15 kg.m

(4) Fourth stage : With torque wrench, tighten up to about 25 kg.m

(5) Fifth stage

: By means of torque wrench, tighten finally in the specified torque. (30 kg.m).

Tighten the bearing cap in the sequence of 4 - 3 - 5 - 2 - 6 - 1 - 7.

Check to see that the assembled crankshaft turns smoothly with hand

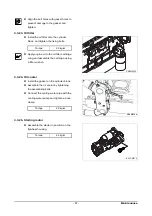

3.3.7. Flywheel housing

Temporarily install the guide bar on the

cylinder block.

Apply gasket to the cylinder block.

Using the dowel pin and guide bar, install

the flywheel housing and tighten the

fixing bolts in a diagonal sequence to

specified torque. (Zigzag method)

3

4

5

6

7

2

1

EAMD078I

EAMD079I

Torque

30 kg

•

m

Oil seal

ED4OM019

Torque

8 kg

•

m

Содержание GL08K

Страница 1: ...950106 050004EN GL08K GAS VEHICLE ENGINE Operation Maintenance Manual ...

Страница 2: ......

Страница 4: ......

Страница 6: ......

Страница 151: ...Maintenance 145 7 Vehicle wiring harness EH3M5012 Truck engine Bus engine ...

Страница 193: ...Appendix 187 Engine Assembly Bus EJ3OM012 ...

Страница 194: ...Appendix 188 Engine Assembly Truck EJ3OM013 ...

Страница 195: ...Special Tool List 950106 080002 ...

Страница 196: ......