Commissioning and Operation

- 151 -

4.5. Tuning the Engine

The purpose of an engine tune-up is to restore power and performance that's been lost through wear,

corrosion or deterioration of one or more parts or components. In the normal operation of an engine,

these changes can take place gradually at a number of points, so that it's seldom advisable to attempt an

improvement in performance by correction of one or two items only. Time will be saved and more lasting

results will be obtained by following a definite and thorough procedure of analysis and correction of all

items affecting power and performance.

Economical, trouble-free operation can better be ensured if a complete tune-up is performed once every

years, preferably in the spring. Components that affect power and performance to be checked are:

Components affecting fuel injection ;

Ignition coil, spark plug, metering valve etc.

Components affecting Intake & exhaust ;

Air cleaner, inter-cooler, turbo charger, silencer, etc.

Components affecting lubrication & cooling ;

Air & oil filter, anti- freeze, etc.

4.6. Maintenance and Care

4.6.1. Periodical inspection and maintenance

In order to insure maximum, trouble-free engine performance at all times, regular inspection, adjustment

and maintenance are vital.

Daily inspections in below figure should be checked every day.

The maintenance should be executed thoroughly at regular internals.

(refer to appendix "General Engine Inspection Cycle".)

4.6.2. Exchanging of lubrication oil

Engine oil and the oil filter are important factors affecting engine life. They affect ease of starting, fuel

economy, combustion chamber deposits and engine wear.

At the end of the break-in period 1,000km (50hours), change the oil sump oil and replace the oil filter

cartridge.

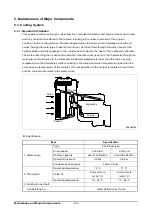

4.6.3. Oil level gauge

Check the oil level in the engine sump daily

with a oil level gauge.

The notches in oil level gauge must

indicate the oil level between the max.

and the min. permissible.

The oil level should be checked with the

engine horizontal and only after it has

been shut down for about 5 minutes.

Examining the viscosity and the

contamination of the oil smeared at the

oil level gauge replace the engine oil if

necessary.

EA4O4001

Содержание GL08K

Страница 1: ...950106 050004EN GL08K GAS VEHICLE ENGINE Operation Maintenance Manual ...

Страница 2: ......

Страница 4: ......

Страница 6: ......

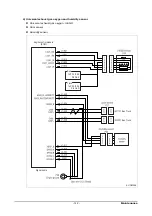

Страница 151: ...Maintenance 145 7 Vehicle wiring harness EH3M5012 Truck engine Bus engine ...

Страница 193: ...Appendix 187 Engine Assembly Bus EJ3OM012 ...

Страница 194: ...Appendix 188 Engine Assembly Truck EJ3OM013 ...

Страница 195: ...Special Tool List 950106 080002 ...

Страница 196: ......