Maintenance of Major Components

- 167 -

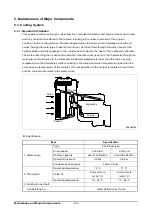

5.4. Belts

The tension of the belts should be checked after every 2,000 hours of operation.

1) Change the belts if necessary

If in the case of a multiple belt drive, wear or differing tensions are found, always replace the

complete set of belts.

2) Checking condition

Check belts for cracks, oil, overheating and wear.

3) Testing by hand

V-belt

By the finger-pressure the belt is

pressed by 10-15mm between the

pulleys in normal condition.(Pressed

midway between the belt pulleys) A

more precise check of the V-belt

tension is possible only by using a V-

belt tension tester.

Poly belt

Poly belt will be properly tensioned if

the deflection force "F" is applied

midway between the belt’s tangent

points with the pulley.

T = 0.015 x S(about 1.5mm per 100mm)

T = 0.015 x *S (mm)

(T : Deflection , S : Span)

(mm)

C : Distance of pulleys (mm),

D : Large pulley diameter (mm),

d : Small pulley diameter (mm)

Press hear

Alternator

pulley

V-belt

Crank pulley

Water pump

pulley

10 ~ 15 mm

EGL0818012

EB5O6001

*S= C

2

(D - d)

2

2

Содержание GL08K

Страница 1: ...950106 050004EN GL08K GAS VEHICLE ENGINE Operation Maintenance Manual ...

Страница 2: ......

Страница 4: ......

Страница 6: ......

Страница 151: ...Maintenance 145 7 Vehicle wiring harness EH3M5012 Truck engine Bus engine ...

Страница 193: ...Appendix 187 Engine Assembly Bus EJ3OM012 ...

Страница 194: ...Appendix 188 Engine Assembly Truck EJ3OM013 ...

Страница 195: ...Special Tool List 950106 080002 ...

Страница 196: ......