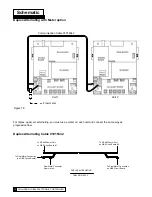

Communication Cable - Multiple Units

NOTE: Disregard this information and proceed to flow sensor schematic (optional) information when installing

single tank configurations.

Multiple units require a communication cable between each unit. Refer to the table below for the cable type, part

number and quantity required. Cables are attached to the RS485 terminal of the circuit board.

Table 2

System

Configuration

Cable Part Number Qty of Cables

required

“Kit” Part Number Qty of blocking

solenoids used.

Duplex Alternating

01016342

1

01016369

2

Duplex Parallel

01016327

1

N/A

0

Triplex Parallel

01016327

2

N/A

0

Duplex Progressive

01016327

1

01016333

2

Triplex Progressive

01016327

2

01016334

3

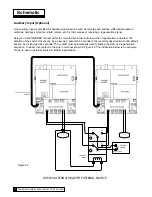

Multiple units can be set up as progressive flow, alternating or parallel operation. Refer to the instructions and

schematics below and on the following pages for connection to the circuit board.

Most multiple tank configurations will also require blocking valves (with the exception of the Hi-Flo 3e softener).

These are used to hold tanks offline until needed. Based on the chart above, you can determine how many

blocking solenoids are used. These solenoids are included in the alternating and progressive flow kits.

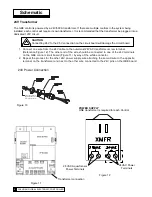

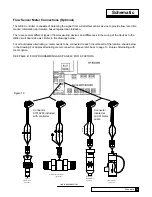

blocking Solenoid Connection (used on Alternating and Progressive flow systems)

The solenoid valve wiring attaches to the Aux Out 4 output connection on the auxiliary circuit board. See

Figure 16 .

Schematic

Schematic

12

11

CULLIGAN GLOBAL ELECTRONIC CONTROLLER

SOL

Figure 16

Содержание GBE

Страница 62: ...Menu Overview Continued on page 61 59 CULLIGAN GLOBAL ELECTRONIC CONTROLLER ...

Страница 63: ...Menu Overview Menu Overview 60 ...

Страница 64: ...Menu Overview Continued from page 59 61 CULLIGAN GLOBAL ELECTRONIC CONTROLLER ...

Страница 65: ...Menu Overview Menu Overview 62 ...

Страница 72: ...Appendix D 69 CULLIGAN GLOBAL ELECTRONIC CONTROLLER ...