Chapter 17

17-40

2. CCD

T-17-42

3. CST

T-17-43

4. CLEANING

T-17-44

5. FIXING

T-17-45

6. PANEL

T-17-46

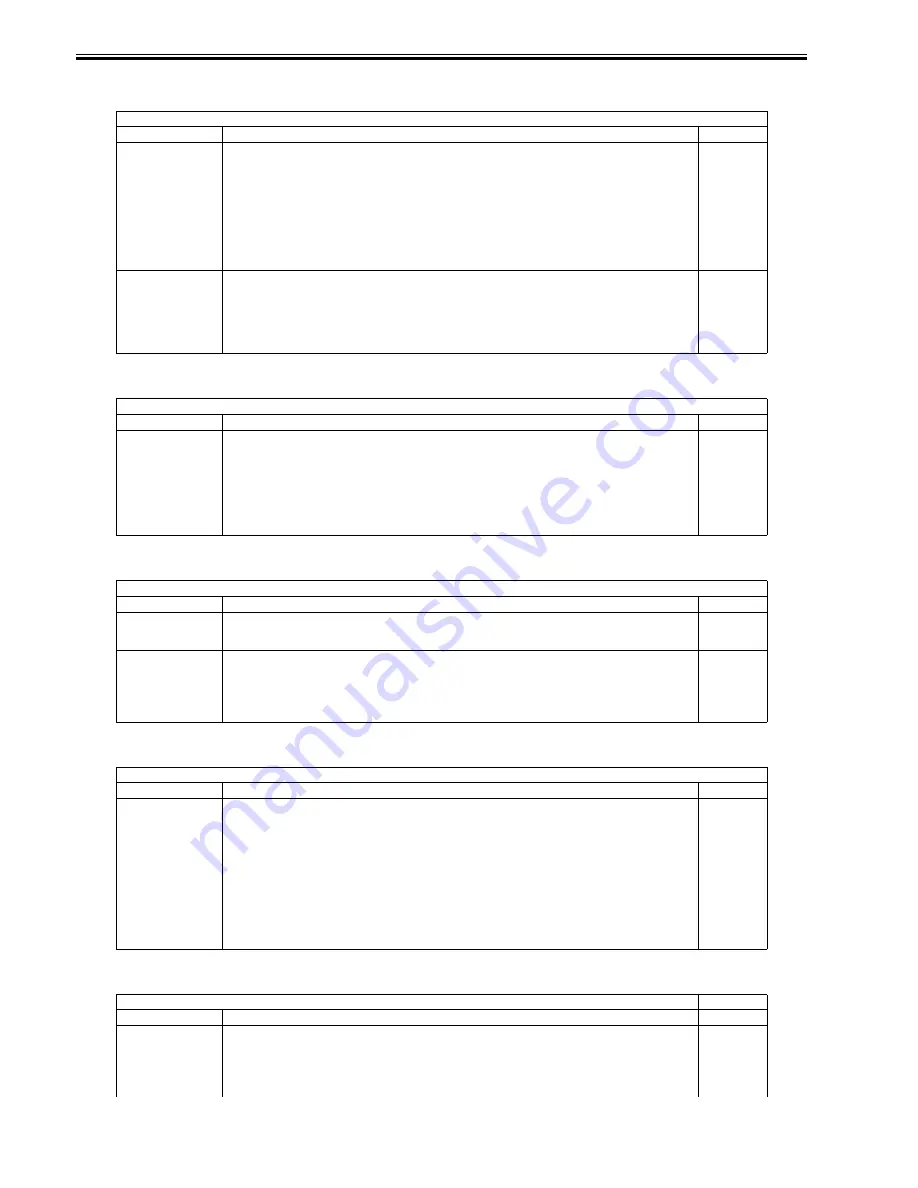

COPIER>FUNCTION>CCD

Sub item

Description

level.

DF-WLVL1/2

Use it to adjust the ADF white level.

Method of Operation

1) Place the type of original most often used by the user on the copyboard glass, and perform the following service mode

item: COPIER>FUNCTION>CCD>DF-WLVL1. (In response, the machine will read the white level for book mode,

checking the transmission quality of the glass for book mode).

2) Place the type of original most often used by the user in the DF, and perform the following service mode item:

COPIER>FUNCTION>CCD>DF-WLVL2. (In response, the machine will read the white level for DF mode (stream

reading mode), checking the transmission quality of the reading glass by reading both sides of the original.)

face reading: computes DFTAR-R/G/B

back reading: computes DFTAR2-R/G/B

Be sure to execute this item in combination with item 2.

1

LUT-ADJ2

CCD gain detailed compensation

Operation procedure

1) Place the 10-gradation chart (D-10 test sheet: FY9-9129) on the document glass surface, as shown in the figure below.

2) Select the item, and press the OK key. Automatic adjustment now commences.

3) Upon completion of the adjustments, operation automatically stops.

4) Set the COPIER>OPTION>BODY>CCD-LUT value to "1."

5) The service mode (COPIER>ADJUST>CCD) item is updated so print out the service sheet and keep it.

2

COPIER>FUNCTION>CST

Sub item

Description

level.

MF-A4R, MF-A6R, MF-

A4

Registers basic value of manual feeder's (DADF's) paper width.

A4R width: 210mm, A6R width: 105mm, A4 width: 297mm

- Once registered, the basic value can be fine-tuned by performing COPIER> ADJUST > CST-ADJ > MF-A4R, MF-

A6R or MF-A4.

Operation method

1) Place A4R size paper in the manual feeder, and set the size guide to the A4R width.

2) In this service mode, select 'MF-A4R' to display the item in reverse. Press the OK key to perform automatic adjustment

and register the value.

3) Repeat Steps 1) and 2) to register the basic values for the A6R and A4 sizes.

1

COPIER>FUNCTION>CLEANING

Sub item

Descripti

level.

2TR-CLN

Secondary transfer roller cleaning

This is for the bias cleaning of the secondary transfer roller.

It is used when the sheets are stained or smudged by dirt in the secondary transfer roller toner.

1

TNR-COAT

Secondary transfer outer roller toner application mode

When the right door is closed while the secondary transfer roller is not dirty (when a new roller is used), the substance

on the secondary transfer roller surfaces rubs against the ITB and becomes adhered to it, leaving areas of the images white

where the substance was rubbed onto the ITB. In order to remove this adhered substance, toner is transferred once to the

secondary transfer outer roller, and then the secondary transfer outer roller is cleaned.

This is used when the secondary transfer roller has been replaced with a new one.

1

COPIER>FUNCTION>FIXING

Sub item

Description

level.

NIP-CHK

Output for automatically measuring fixing nip width

The fixing nip width automatic measurement is started, and the measurement sheet is printed. The two-sided printing

operation is performed with solid magenta printed on the first side and nothing printed on the second side, and nipping

is performed when the second side is fixed.

This is used in order to check the nip width when the fixing unit, fixing film unit or pressure roller is replaced.

Operating procedure

1) Place A4 (LTR) size sheets in the stack bypass tray.

2) Press the OK key. (The paper in the stack bypass tray is fed.)

3) The sheets which have been fed stop temporarily at the fixing nip unit, and are delivered 15 seconds later.

4) Check that the nip width of the delivered sheets corresponds to the rating.

Nip width rating

Center area [b in figure below]: 8 mm or more

Left and right edges [a, c in figure below]: 1 mm or less

1

COPIER>FUNCTION>PANEL

Sub item

Description

level.

LCD-CHK

Used to check missing dots in LCD.

Operation method

1) Select this item, then press the OK key to start the operation.

The touch panel's front surface should light repeatedly in the sequence: white, black, red, green and blue. (Check that it

does.)

2) Press the stop key (the clear key on printer models) to end the operation.

1

Содержание iR C3380 series

Страница 1: ...Aug 29 2006 Service Manual iR C3380 2880 Series...

Страница 2: ......

Страница 6: ......

Страница 23: ...Chapter 1 Introduction...

Страница 24: ......

Страница 26: ......

Страница 52: ......

Страница 53: ...Chapter 2 Installation...

Страница 54: ......

Страница 127: ...Chapter 3 Basic Operation...

Страница 128: ......

Страница 130: ......

Страница 136: ......

Страница 137: ...Chapter 4 Main Controller...

Страница 138: ......

Страница 160: ......

Страница 161: ...Chapter 5 Original Exposure System...

Страница 162: ......

Страница 188: ...Chapter 5 5 24 F 5 68 4 Remove the original sensor 2 hook 1 F 5 69...

Страница 189: ...Chapter 6 Laser Exposure...

Страница 190: ......

Страница 192: ......

Страница 206: ......

Страница 207: ...Chapter 7 Image Formation...

Страница 208: ......

Страница 256: ......

Страница 257: ...Chapter 8 Pickup Feeding System...

Страница 258: ......

Страница 262: ......

Страница 303: ...Chapter 9 Fixing System...

Страница 304: ......

Страница 306: ......

Страница 321: ...Chapter 10 Externals and Controls...

Страница 322: ......

Страница 326: ......

Страница 336: ...Chapter 10 10 10 F 10 10 2 Remove the check mark from SNMP Status Enabled...

Страница 337: ...Chapter 10 10 11 F 10 11...

Страница 359: ...Chapter 11 MEAP...

Страница 360: ......

Страница 362: ......

Страница 401: ...Chapter 12 RDS...

Страница 402: ......

Страница 404: ......

Страница 411: ...Chapter 13 Maintenance and Inspection...

Страница 412: ......

Страница 414: ......

Страница 416: ...Chapter 13 13 2 F 13 1 8 9 1 2 3 3 5 6 7 10 11 12 13 14 4...

Страница 421: ...Chapter 14 Standards and Adjustments...

Страница 422: ......

Страница 424: ......

Страница 431: ...Chapter 15 Correcting Faulty Images...

Страница 432: ......

Страница 434: ......

Страница 459: ...Chapter 16 Self Diagnosis...

Страница 460: ......

Страница 462: ......

Страница 481: ...Chapter 17 Service Mode...

Страница 482: ......

Страница 484: ......

Страница 571: ...Chapter 18 Upgrading...

Страница 572: ......

Страница 574: ......

Страница 603: ...Chapter 19 Service Tools...

Страница 604: ......

Страница 605: ...Contents Contents 19 1 Service Tools 19 1 19 1 1 Special Tools 19 1 19 1 2 Solvents and Oils 19 2...

Страница 606: ......

Страница 609: ...Aug 29 2006...

Страница 610: ......