Chapter 6

6-2

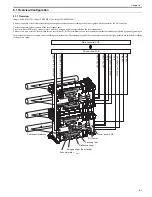

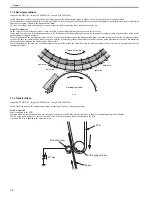

The following is the operational sequence at printing.

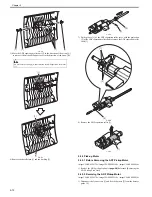

1) Upon reception of a print command from the main controller, the DC controller rotates the 2 scanner motors.

The 2 polygon mirrors rotate in conjunction with the scanner motors.

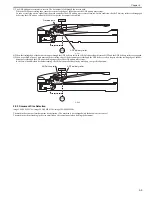

2) The DC controller allows the laser diode on the laser driver PCB to emit light.

The light of the laser diode (laser beam) is reflected by the polygon mirror and received by the BD sensor on the laser driver PCB.

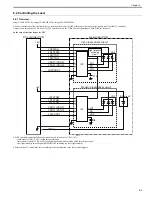

3) The laser driver PCB outputs the /BD input signals (/BD1I, /BD3I) to the DC controller PCB.

4) The DC controller monitors the rotational speed of the scanner motor with the /BDI signals input timing to control the scanner motor to rotate at constant speed.

When the scanner motor rotates at constant speed, the DC controller outputs the video signals sent from the main controller to the laser driver PCB.

5) In the laser driver PCB, the laser diode is emitted depending on the video signals and the laser beam is radiated.

6) The laser beams are reflected by the polygon mirror rotating at the constant speed, and reach the photosensitive drum via the focusing lens and the reflection

mirror.

The focusing lens corrects the route of the laser beam to maintain the constant scanning speed on the photosensitive drum.

7) When the photosensitive drum rotates at constant speed and the laser beams scan vertically to its rotation, a latent image is formed on the drum.

MEMO:

- Only one /BDI signal is generated per scanner motor.

The /BDI signals of the scanner motor for M/C is generated based on the M laser reflected light, and the /BDI signals of the scanner motor for Y/Bk is generated

based on the Y laser reflected light.

The DC controller generates the /BDI signals for four colors according to these /BDI signals and send them to the main controller.

- The machine scans two lines with one polygon mirror. Therefore the scanning direction depends on the color. (The direction for M/Y is right-end write start

scanning direction and that for C/Bk is left-end write start scanning direction relative to the print side of paper.)

Содержание imageCLASS MF8450c

Страница 16: ...Chapter 1 Introduction ...

Страница 55: ...Chapter 2 Basic Operation ...

Страница 61: ...Chapter 3 Main Controller ...

Страница 75: ...Chapter 4 Original Exposure System ...

Страница 88: ...Chapter 5 Original Feeding System ...

Страница 105: ...Chapter 6 Laser Exposure ...

Страница 113: ...Chapter 7 Image Formation ...

Страница 150: ...Chapter 8 Pickup and Feed System ...

Страница 184: ...Chapter 9 Fixing System ...

Страница 200: ...Chapter 10 External and Controls ...

Страница 230: ...Chapter 11 Maintenance and Inspection ...

Страница 233: ...Chapter 12 Measurement and Adjustments ...

Страница 237: ...Chapter 13 Correcting Faulty Images ...

Страница 251: ...Chapter 13 13 13 13 3 5 PCBs 13 3 5 1 PCBs 0019 5065 imageCLASS MF9170c imageCLASS MF9150c imageCLASS MF8450c ...

Страница 256: ...Chapter 13 13 18 F 13 19 21 22 28 29 30 31 24 14 15 16 23 26 25 32 27 20 19 18 17 2 13 6 10 33 1 8 4 3 12 11 5 7 9 ...

Страница 260: ...Chapter 14 Error Code ...

Страница 272: ...Chapter 15 Special Management Mode ...

Страница 280: ...Chapter 16 Service Mode ...

Страница 322: ...Chapter 17 Upgrading ...

Страница 327: ...Chapter 17 17 4 3 Click Next F 17 4 4 Select a USB connected device and click Next F 17 5 ...

Страница 328: ...Chapter 17 17 5 5 Click Start F 17 6 6 Click Yes F 17 7 Download will be started F 17 8 ...

Страница 330: ...Chapter 18 Service Tools ...

Страница 334: ...Appendix ...

Страница 349: ......