2-8

D. Kinked or binding links.

E. Excessive wear.

The presence of any of the conditions requires drive

chain replacement.

NOTE: If the drive chain is worn or damaged, the

sprockets may also be worn or damaged. Inspect

the sprockets for worn, broken, or damaged teeth.

Always inspect the sprockets when a new drive

chain is being installed.

CLEANING AND LUBRICATING

The drive chain should be cleaned and lubricated fre-

quently to prolong chain and sprocket life. Use the fol-

lowing procedure to clean and lubricate the chain.

NOTE: This ATV is equipped with an O-ring type

roller chain. Each link incorporates small O-rings

to seal out water and dirt. Care should be taken to

choose cleaning solutions and lubricants that are

suitable for O-ring type chains.

1. Using a suitable, nonflammable cleaning solution,

thoroughly wash the chain and sprockets.

2. Allow the chain to dry; then apply a dry, graph-

ite-based lubricant to the chain.

NOTE: The drive chain should be lubricated with

a dry, graphite-based chain lubricant. By using a

dry, graphite-based chain lubricant, dirt build-up

on the drive chain will be minimized.

ADJUSTING TENSION

To adjust the drive chain tension, use the following

procedure.

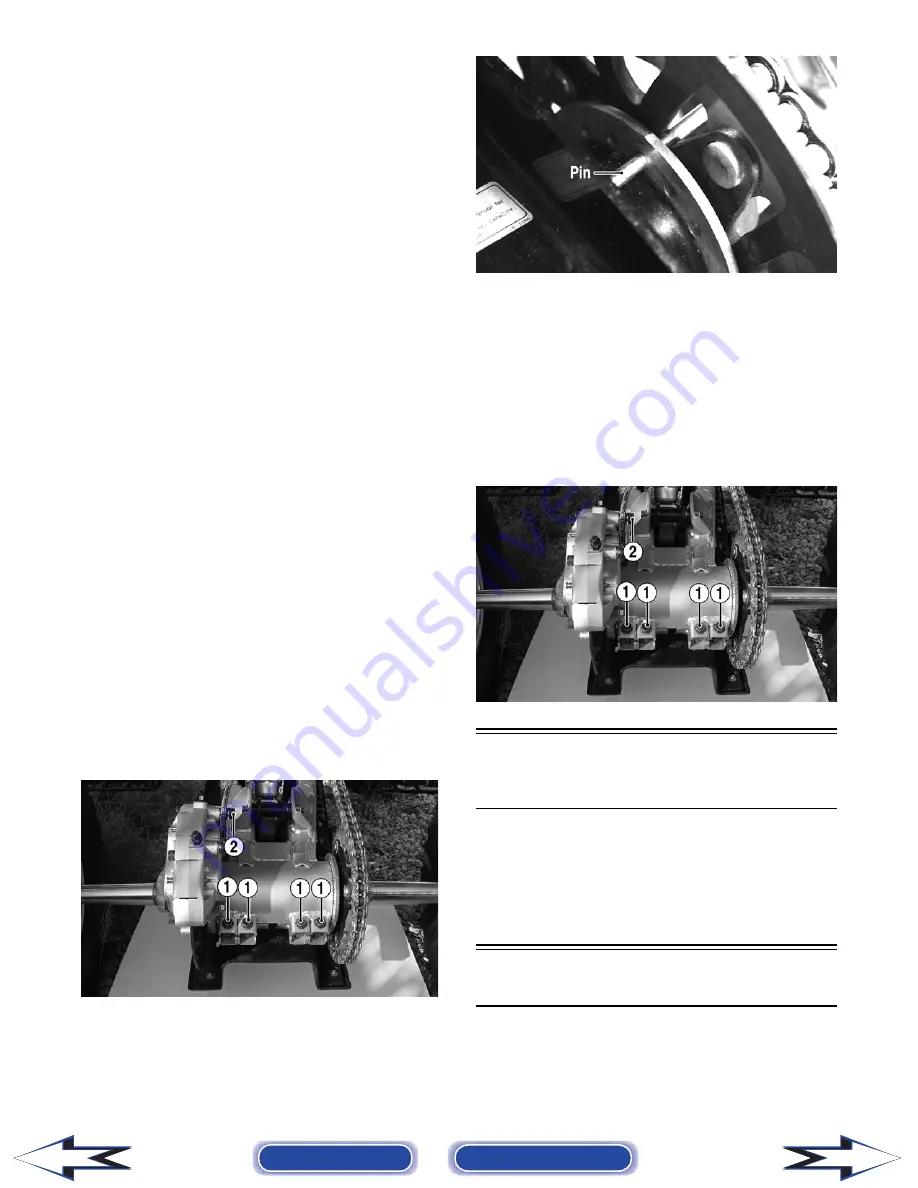

1. Loosen the four cap screws (1) at the rear of the

axle housing; then loosen the cap screw (2) on the

front of the brake caliper.

KM902A

2. Install an appropriate pin through the axle hub and

rear sprocket.

KM158A

3. With a person seated on the ATV, check chain ten-

sion at the mid-point of the chain.

NOTE: Chain “slack” should be within a range of

30-40 mm (1.2-1.6 in.).

4. Push the ATV forward to tighten chain tension;

push the ATV backward to loosen chain tension.

5. Tighten the four cap screws (1) to 29 ft-lb; then

tighten the cap screw (2) to 29 ft-lb.

KM902A

Driveshaft/Coupling

(250 Utility)

The following drive system components should be

inspected periodically to ensure proper operation.

A. Spline lateral movement (slop).

B. Coupling not cracked, damaged, or worn.

Nuts/Bolts/Cap Screws

Tighten all nuts, bolts, and cap screws. Make sure riv-

ets holding components together are tight. Replace all

loose rivets. Care must be taken that all calibrated

nuts, bolts, and cap screws are tightened to specifica-

tions (see Section 1).

Back to TOC

Back to Section TOC

Next

Back

Содержание ATV 250 Utility 2009

Страница 1: ......