JOHNSON CONTROLS

178

FORM 150.67-NM2 (209)

Service and Troubleshooting

Pressing the

↑

(UP) arrow key will energize the liquid

line solenoid valve and “OFF” will change to “ON” in

the display as the LLSV is energized. Energizing and

de-energizing outputs may be useful during trouble-

shooting.

SERVICE MODE – CHILLER CONFIGURATION

After the Outputs are displayed, the next group of

displays relate to chiller con

fi

guration and start/hour

counters. Data logging, soft start, refrigerant type, pump

control selection and expansion valve type all must be

programmed to match actual chiller con

fi

guration.

Soft start (disabled), Refrigerant Type

(R410A), and Expansion Valve Type

(Thermostatic), and North American

Feature (Enabled) MUST be properly

programmed or damage to compres-

sors and other system components

may result.

Following is a list of chiller con

fi

guration selections, in

order of appearance:

DATA LOGGING MODE = : DO NOT MODIFY

DATA LOGGING TIMER = : DO NOT MODIFY

SOFT START

REFRIGERANT TYPE

EXPANSION VALVE TYPE

REMOTE TEMP RESET OPTION

REMOTE INPUT SERVICE TIME

FEATURE SET

PUMP CONTROL SELECTION

SYS 1 HOURS

SYS 2 HOURS

SYS 1 STARTS

SYS 2 STARTS

The last displays shown on the above list are for the ac-

cumulated run and start timers for each system. All val-

ues can also be changed using the

↑

(UP) and

↓

(Down)

arrow keys, but under normal circumstances would not

be required or advised. After the last start display, the

micro will display the

fi

rst programmable value under

the PROGRAM key.

SERVICE MODE – ANALOG & DIGITAL

INPUTS

After entering Service Mode (PROGRAM

,

all digital and analog inputs to the microboard can be

viewed by pressing the OPER DATA key.

After pressing

the OPER DATA key, the

↑

(UP) arrow and

↓

(DOWN)

arrow keys are used to scroll through the analog and

digital inputs.

Following is the order of analog and digital inputs that

will appear when sequenced with the

Down) arrow

key:

(analog inputs)

SYS 1 SUCT PRESSURE

UNIT TYPE

SYS 1 *DISCH PRESSURE

SYS 1** SUCTION TEMP.

SYS 2** SUCTION TEMP.

AMBIENT AIR TEMP.

LEAVING LIQUID TEMP.

RETURN LIQUID TEMP.

SYS 2 SUCTION PRESSURE

SYS 2 SPARE

SYS 2 *DISCH PRESSURE

SYS 1 MTR VOLTS

SYS 2 MTR VOLTS

(digital inputs)

PWM TEMP RESET INPUT

LOAD LIMIT INPUT

FLOW SW / REM START

SPARE

SINGLE SYSTEM SELECT

SYS 1 MP / HPCO INPUT

SYS 2 MP / HPCO INPUT

The analog inputs will display the input connection,

the temperature or pressure, and corresponding input

voltage such as:

This example indicates that the system 1 suction

pressure input is connected to plug 7 – pin 10 (J7-10)

on the I/O board. It indicates that the voltage is 2.1

volts dc which corresponds to 81 PSIG (5.6 bars)

suction pressure.

S Y S 1 S U C T P R J 7 - 1 0

2 . 1 V D C = 8 1 P S I G

* The discharge pressure transducer is optional on some models.

** The suction temp. sensor is on EEV units only.

Summary of Contents for YCAL0019

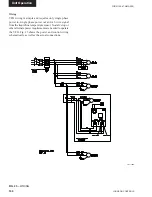

Page 55: ...FORM 150 67 NM2 209 55 JOHNSON CONTROLS 5 5 ELEMENTARY WIRING DIAGRAM CON T LD12699D...

Page 57: ...FORM 150 67 NM2 209 57 JOHNSON CONTROLS 5 5 ELEMENTARY WIRING DIAGRAM CON T LD12693C...

Page 59: ...FORM 150 67 NM2 209 59 JOHNSON CONTROLS 5 5 ELEMENTARY WIRING DIAGRAM CON T LD 12198...

Page 61: ...FORM 150 67 NM2 209 61 JOHNSON CONTROLS 5 5 LD12702 ELEMENTARY WIRING DIAGRAM CON T...

Page 63: ...FORM 150 67 NM2 209 63 JOHNSON CONTROLS 5 5 LD12696 ELEMENTARY WIRING DIAGRAM CON T...

Page 65: ...FORM 150 67 NM2 209 65 JOHNSON CONTROLS 5 5 CONNECTION WIRING DIAGRAM CON T LD12703B...

Page 67: ...FORM 150 67 NM2 209 67 JOHNSON CONTROLS 5 5 CONNECTION WIRING DIAGRAM CON T LD12697B...