JOHNSON CONTROLS

168

FORM 150.67-NM2 (209)

Unit Operation

General

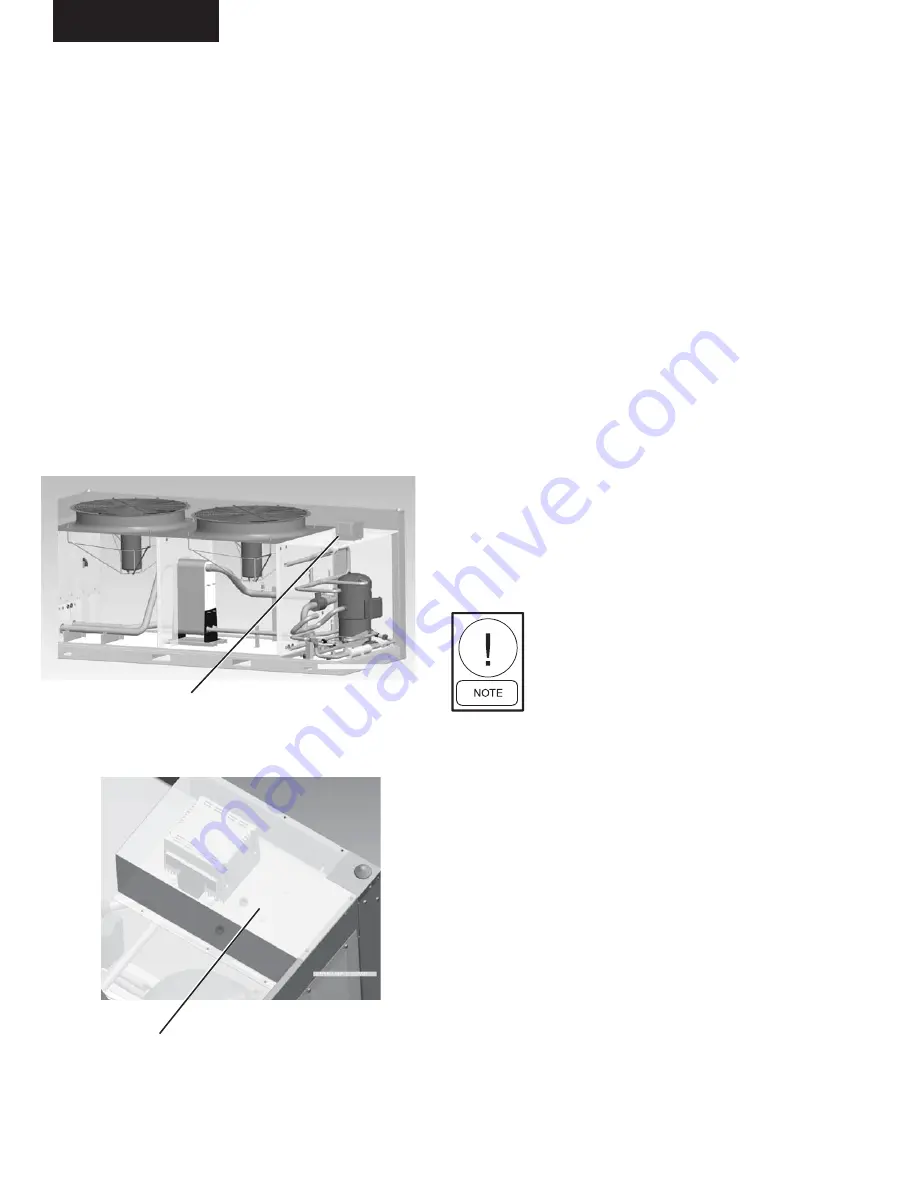

The low ambient option consists of a VFD (Variable

Frequency Drive) that controls the speed of the

fi

rst fan

(Fan 1) in the fan staging sequence. The VFD is located on

the top of chiller above the compressor section. Examples

of the typical VFD location and enclosure mountings are

shown in Figs. 26 & 27.

The VFD will control fan speed when only a single fan is

running on a system. As discharge pressure rises and falls,

the fan speed will be increased from zero RPM to full

speed. As discharge pressure continues to rise, the VFD

will operate the fan at full speed and the second fan will be

brought on in a system, if needed. Whenever the second

fan is brought on, the inverter will already be running the

fi

rst fan at full speed. When discharge pressure falls, the

chiller microprocessor will turn the second fan off by de-

energizing the fan contactor.

If pressure continues to fall, VFD speed will decrease in

an effort to maintain discharge pressure. Speed may drop

to the point where the VFD turns the fan completely off or

virtually off with a continued drop in pressure.

The VFD control input signal is from the discharge

pressure transducer in the respective system. The

transducer signal feeds both the chiller microprocessor

board and the VFD. The VFD controls the fan speed based

on discharge pressure.

The VFD will control the fan speed not only in low

ambient conditions, but in all ambients based on discharge

pressure. Speed control of the respective system will

occur whenever high voltage power is applied to the

VFD power inputs through the 7M contactor. The chiller

microprocessor will energize the 7M and 10M contactors

whenever the system liquid line solenoid is energized.

The VFD controls the speed of the fan based on a discharge

pressure setpoint and a differential control range. When

a compressor starts in a system, the inverter is activated

through the 7M contactor, which is controlled from the

respective liquid line solenoid valve control signal. At

discharge pressures below 260 PSIG, the VFD will turn the

fan off or speed will be reduced to all but small movements

in fan rotation.

The pressures indicated in this section

describing the VFD control will vary from

VFD to VFD. Expect tolerances for the

entire pressure range of control to poten-

tially shift -0 PSIG/+24 PSIG.

The VFD will ramp up the speed of the fan as pressure rises

above the low end of the speed control range. Throughout

the pressure control range, the VFD controls the speed of

the fan based on a discharge pressure in the range of approx

260-292 PSIG. At pressures above 292 PSIG, the VFD will

run the system fan at full speed.

As pressure drops below 292 PSIG, the VFD will slow

the speed of the fan to try to maintain discharge pressure

within the control range. The VFD will try to maintain

pressure in the range of 260-292 PSIG by raising and

lowering the speed of the fan. If pressure drops below

260 PSIG, the VFD will virtually turn the system fan

completely off. Some slight fan movement or very slow

rotation may be noted, although the fan may appear to stop

completely.

FIG. 26 –

TYPICAL VFD ENCLOSURE LOCATIONS

VFD Enclosure Location

LD12080

VFD Enclosure

LD12081

FIG. 27-

TYPICAL VFD ENCLOSURE

CONFIGURATIONS

LOW AMBIENT FAN CONTROL OPTION

YCAL0033

Summary of Contents for YCAL0019

Page 55: ...FORM 150 67 NM2 209 55 JOHNSON CONTROLS 5 5 ELEMENTARY WIRING DIAGRAM CON T LD12699D...

Page 57: ...FORM 150 67 NM2 209 57 JOHNSON CONTROLS 5 5 ELEMENTARY WIRING DIAGRAM CON T LD12693C...

Page 59: ...FORM 150 67 NM2 209 59 JOHNSON CONTROLS 5 5 ELEMENTARY WIRING DIAGRAM CON T LD 12198...

Page 61: ...FORM 150 67 NM2 209 61 JOHNSON CONTROLS 5 5 LD12702 ELEMENTARY WIRING DIAGRAM CON T...

Page 63: ...FORM 150 67 NM2 209 63 JOHNSON CONTROLS 5 5 LD12696 ELEMENTARY WIRING DIAGRAM CON T...

Page 65: ...FORM 150 67 NM2 209 65 JOHNSON CONTROLS 5 5 CONNECTION WIRING DIAGRAM CON T LD12703B...

Page 67: ...FORM 150 67 NM2 209 67 JOHNSON CONTROLS 5 5 CONNECTION WIRING DIAGRAM CON T LD12697B...