JOHNSON CONTROLS

158

FORM 150.67-NM2 (209)

Unit Operation

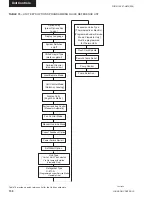

FIG. 18 –

LEAVING WATER TEMPERATURE CONTROL EXAMPLE

Hot gas, if present, will be the

fi

nal step of capacity. Hot

gas is energized when only a single compressor is running

and LWT<SP. Hot gas is turned off as temperature rises

when LWT>SP + CR/2. If temperature remains below

the setpoint low limit on the lowest step of capacity, the

micro will close the liquid line solenoid, after turning

off hot gas, and pump the system down before turning

off the last compressor in a system.

The leaving chilled liquid setpoint is programmable

from 40 °F to 70 °F (4.4 °C to 21.1 °C) in water chilling

mode and from 10 °F to 70 °F (-12.2 °C to 21.1 °C) in

glycol chilling mode. In both modes, the cooling range

can be from +/-1.5 °F to +/-2.5 °F (+/-.83 °C to 1.39

°C).leaving chilled liquid control

LEAVING CHILLED LIQUID CONTROL

OVERRIDE TO REDUCE CYCLING

To avoid compressor cycling the micro will adjust the

setpoint upward temporarily. The last run time of the

system will be saved. If the last run time was greater

than 5 minutes, no action is to be taken. If the last run

time for the lead system was less than 5 minutes, the

Leaving Water Temp. Control – Compressor Staging

Setpoint = 46.0 °F (7.8 °C) Range = +/- 2 °F(1.1 °C)

30 sec.

Control Range

60 sec.

unloading

(no compressor staging)

loading

44.0

°F

46.0

°F

48.0°

(6.7

°C)

(7.8

°C)

(8.9

°C)

Low Limit

Setpoint

High limit

LWT

LEAVING CHILLED LIQUID SYSTEM LEAD/LAG

AND COMPRESSOR SEQUENCING

A Lead/Lag option may be selected to help equalize

average run hours between systems with 2 refrigerant

systems. This may be programmed under the OPTIONS

key. Auto Lead/Lag allows automatic Lead/Lag of the two

systems based on average run hours of the compressors

in each system. Manual Lead/Lag selects speci

fi

cally the

sequence which the micro starts systems.

On a hot water start, once a system starts, it will turn on all

compressors before the next system starts a compressor.

The microprocessor will sequence compressors within

each circuit to maximize individual compressor run time

on individual compressors within a system to prevent

short cycling.

Each compressor in a system will be assigned an

arbitrary priority number 1, 2, or 1, 2, 3. The non-running

compressor within a system with the lowest priority

number will always be the next compressor to start. The

running compressor with priority number 1 will always

be the next to shut off. Whenever a compressor is shut

off, the priority numbers of all compressors will be

decreased by 1 with wrap-around. This control scheme

assures the same compressor does not repeatedly cycle

on and off.

Once the second system starts a compressor on a 2

system chillers, the micro will attempt to equally load

each system as long as the system is not limiting or

pumping down. Once this occurs, loading and unloading

will alternate between systems, loading the lead system

fi

rst or unloading the lag system

fi

rst.

0 1

2

3

4

5

6

LAST RUN TIME OF LEAD SYSTEM (MINUTES)

SETPOINT

ADJUST

(DEG. F)

6

5

4

3

2

1

0

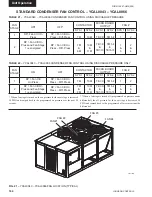

FIG. 19 –

SETPOINT ADJUST

microprocessor will increase the setpoint high limit

according to the chart at right, with a maximum value

allowed of 50 °F (See Fig. 19).

If adding the setpoint adjust value to the setpoint high

limit causes the setpoint high limit to be greater than 50

°F, the setpoint high limit will be set to 50 °F, and the

difference will be added to the setpoint low limit.

Once a system runs for greater than 5 minutes, the

setpoint adjust will be set back to 0. This will occur

while the system is still running.

Summary of Contents for YCAL0019

Page 55: ...FORM 150 67 NM2 209 55 JOHNSON CONTROLS 5 5 ELEMENTARY WIRING DIAGRAM CON T LD12699D...

Page 57: ...FORM 150 67 NM2 209 57 JOHNSON CONTROLS 5 5 ELEMENTARY WIRING DIAGRAM CON T LD12693C...

Page 59: ...FORM 150 67 NM2 209 59 JOHNSON CONTROLS 5 5 ELEMENTARY WIRING DIAGRAM CON T LD 12198...

Page 61: ...FORM 150 67 NM2 209 61 JOHNSON CONTROLS 5 5 LD12702 ELEMENTARY WIRING DIAGRAM CON T...

Page 63: ...FORM 150 67 NM2 209 63 JOHNSON CONTROLS 5 5 LD12696 ELEMENTARY WIRING DIAGRAM CON T...

Page 65: ...FORM 150 67 NM2 209 65 JOHNSON CONTROLS 5 5 CONNECTION WIRING DIAGRAM CON T LD12703B...

Page 67: ...FORM 150 67 NM2 209 67 JOHNSON CONTROLS 5 5 CONNECTION WIRING DIAGRAM CON T LD12697B...