17.3.3.2 Fitting a new pumphead

Fitting a new pumphead is a similar procedure of the pumphead removal. This procedure is written based on a

new pumphead which would not contain any previous chemical. Do not fit a used pumphead.

Procedure

1. Remove the new pumphead from its packaging.

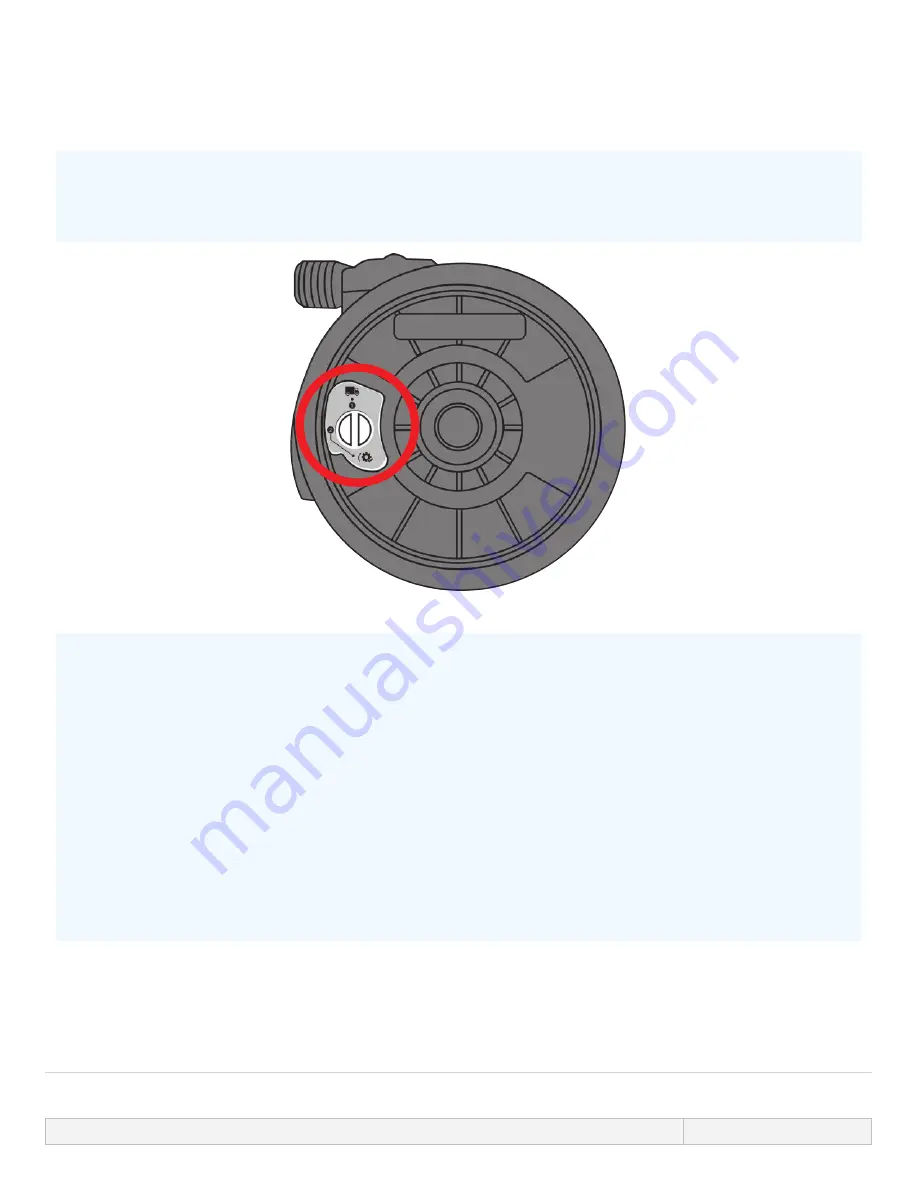

2. Turn pressure valve on pumphead to the 'in use' position (not specific step is not required for CWT

models).

In use position

Procedure

3. Align the new pumphead with the pump drive shaft and slide into position on the pump housing.

4. Rotate the pumphead in an anti-clockwise direction by approximately 15° to engage the retaining lugs.

5. Lock the pumphead into position using the pumphead locking lever.

6. Connect the input and output connections to the pumphead.

7. Reconnect the electrical power to the pump

8. Confirm which pumphead has been fitted using the keys on the HMI

9. Press start and run the pumphead for a few revolutions.

10. Stop the pump and isolate it from the power supply, check the locking lever is in the locked position.

11. Re-connect the input and output connections to the pumphead.

12. Reset the volume or hours counters to begin monitoring life of the replacement pumphead so that it

can be changed prior to failure.

17 MAINTENANCE

191