20. Exhaust System

20.1

Exhaust manifold

20.1.1 General description

Data and dimension

Multiduct

Material:

Nodular cast iron

Weight:

60 kg

Test pressure:

10 bar

(water side)

Exhaust pipes

Material: Special, heat resis-

tant alloy nodular cast iron

Bellows

Multiply design

Material: Heat resistant steel

The exhaust manifold is fitted between the cylinder head and the

turbocharger. The manifold consists of the multiducts (3) and the

exhaust pipes (2) with expansion bellows (1). The manifold is

enclosed into an insulating box of sandwich design.

The turbocharging concept depends on the type of installation,

alternatively a specific type of pulse charging or a constant

pressure charging are used. The exhaust gases connected to one

pipe are discharged from each cylinder during the period when

the other cylinders connected to the same pipe have the exhaust

valve closed. This gives an equal flow of gases to the turbocharger

without any disturbing gas pulses to the other cylinders connected

to the common pipe.

The multiduct, between the cylinder head and the exhaust

pipes, acts as a bracket for the whole exhaust manifold, including

the insulation box. The multiduct is cooled by the cooling water

discharging from the cylinder head. The multiducts are vented

through a venting pipe along the engine. The cooling water flows

from the multiducts (3) through the water pipes (4) in the cooling

water box. The multiduct also connects the air receiver in the

engine block with the inlet air channel in the cylinder head. All

the surfaces, engine block/multiduct, cylinder head/ multiduct

and exhaust pipes/multiduct are sealed off.

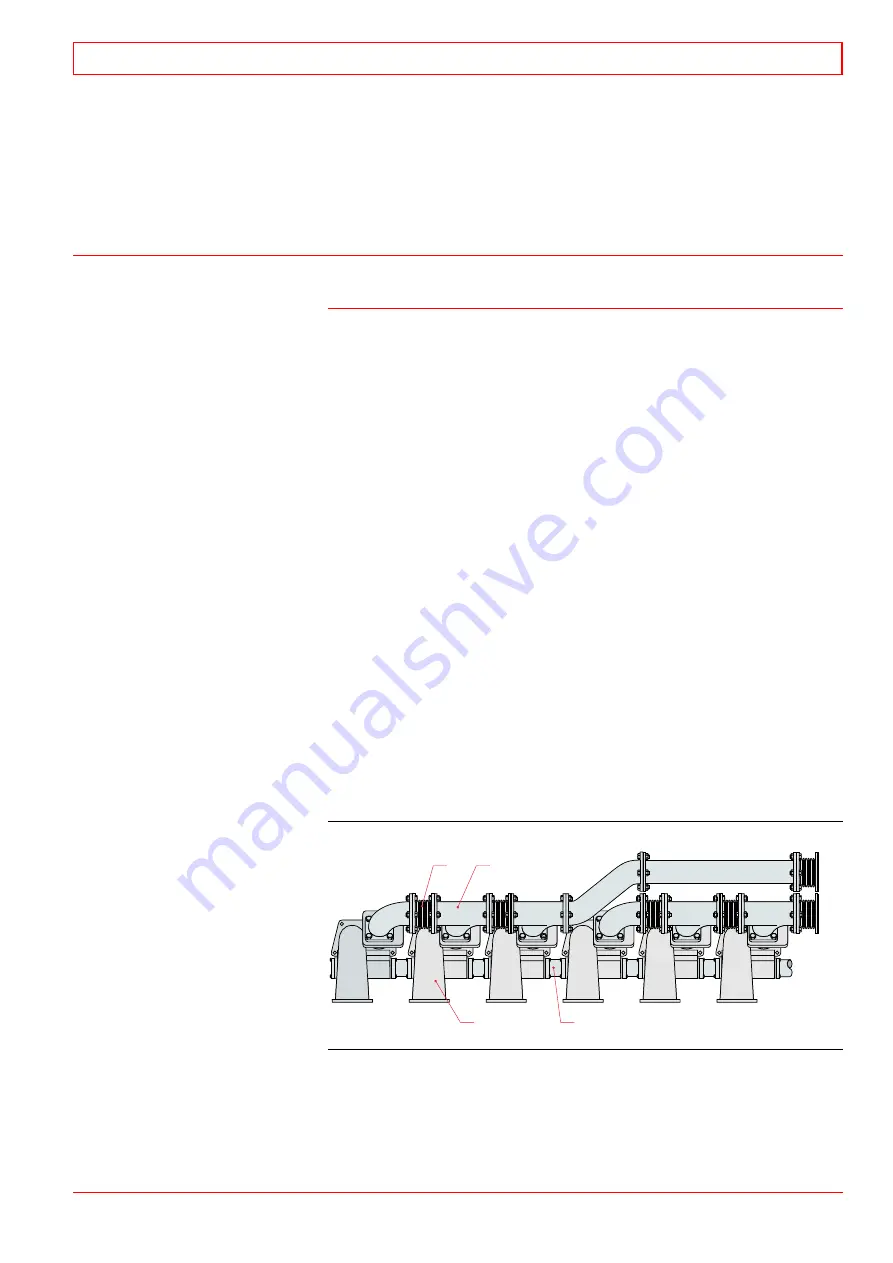

Exhaust manifold

The multiduct is rigidly mounted towards the cylinder head.

The exhaust pipes are cast of special alloy nodular cast iron,

with separate sections for each cylinder. Metal bellows of multiply

type absorb the heat expansion.

1. Bellows

2. Exhaust gas pipe

3. Multiduct

4. Water pipe

1

3

2

4

Fig 20-1

4020019601

32-200045

Exhaust System

20

WÄRTSILÄ 32

20 - 1

Summary of Contents for PAAE051728

Page 4: ......

Page 18: ...Appendix B Welding Precautions 200640 00 6...

Page 26: ...01 Main Data Operating Data and General Design 32 200634 01 01 8 W RTSIL 32...

Page 60: ...Appendix A Environmental Hazards 200507 02A 10...

Page 68: ...Page 7 7 Document No 4V92A0645 Rev j...

Page 84: ...03 Start Stop and Operation 32 200402 04 03 12 W RTSIL 32...

Page 98: ...04 Maintenance Schedule 32 200623 01 04 14 W RTSIL 32...

Page 154: ...07 Tightening Torques and Use of Hydraulic Tools 32 200643 01 07 30 W RTSIL 32...

Page 162: ...08 Operating Troubles Emergency Operation 32 200402 01 08 8 W RTSIL 32...

Page 164: ...Specific Installation Data 2005 01 09 2...

Page 178: ...10 Engine Block with Bearings Oil Sump and Cylinder Liner 32 200150 10 14 W RTSIL 32 34SG...

Page 216: ...Appendix A Testing of cylinder tightness 32 200142 A 4 W rtsil 20 32 34...

Page 226: ...13 Camshaft Driving Gear 32 200546 02 13 10 W RTSIL 32...

Page 254: ...15 Turbocharging and Air Cooling 32 200549 10 15 20 W RTSIL 32...

Page 274: ...16 Injection System 32 200627 01 16 20 W RTSIL 32...

Page 280: ...Fuel System 32 200508 07 17 6 W RTSIL 32...

Page 314: ...19 Cooling Water System 32 200050 19 14 W RTSIL 32...

Page 394: ...23 Instrumentation and Automation 32 200115 II 23 60 W RTSIL 32...