22.3.3 Electro-pneumatic overspeed trip device

22.3.3.1 Maintenance

For maintenance schedule, see chapter 04.

Removal

1 Remove the valve from the injection pump.

2 Remove the piston (2)

by tapping the cylinder (3) against a

piece of wood. If the piston is stuck, press it out by connecting a

grease gun with a suitable adapter to the air supply of the cylinder.

Caution!

If compressed air is used, the piston (2) may be ejected with

such a force that it may cause injuries or damages.

Mounting

3 Ensure that there are no sharp corners or dents

on the

piston (2) or in the cylinder (3). Smoothen if necessary. Apply

a suitable grease and take care not to damage the seal ring

when mounting the piston (2).

a)

Check of stop position

·

Set the stop lever in the work position and the terminal shaft

lever in the max. fuel position.

·

Press the STOP-button on the engine. (Stop sequence is

activated approximately 1 min.)

Note! The starting air

supply should be open.

·

Check that the fuel rack positions is less than 5 mm.

b)

Adjustment of stop position

·

The electro-pneumatic overspeed trip device requires no

adjustment.

·

If a fuel rack position of less than 5 mm cannot be obtained,

check for wear.

c)

Check of tripping speed

·

See section 22.5.3.

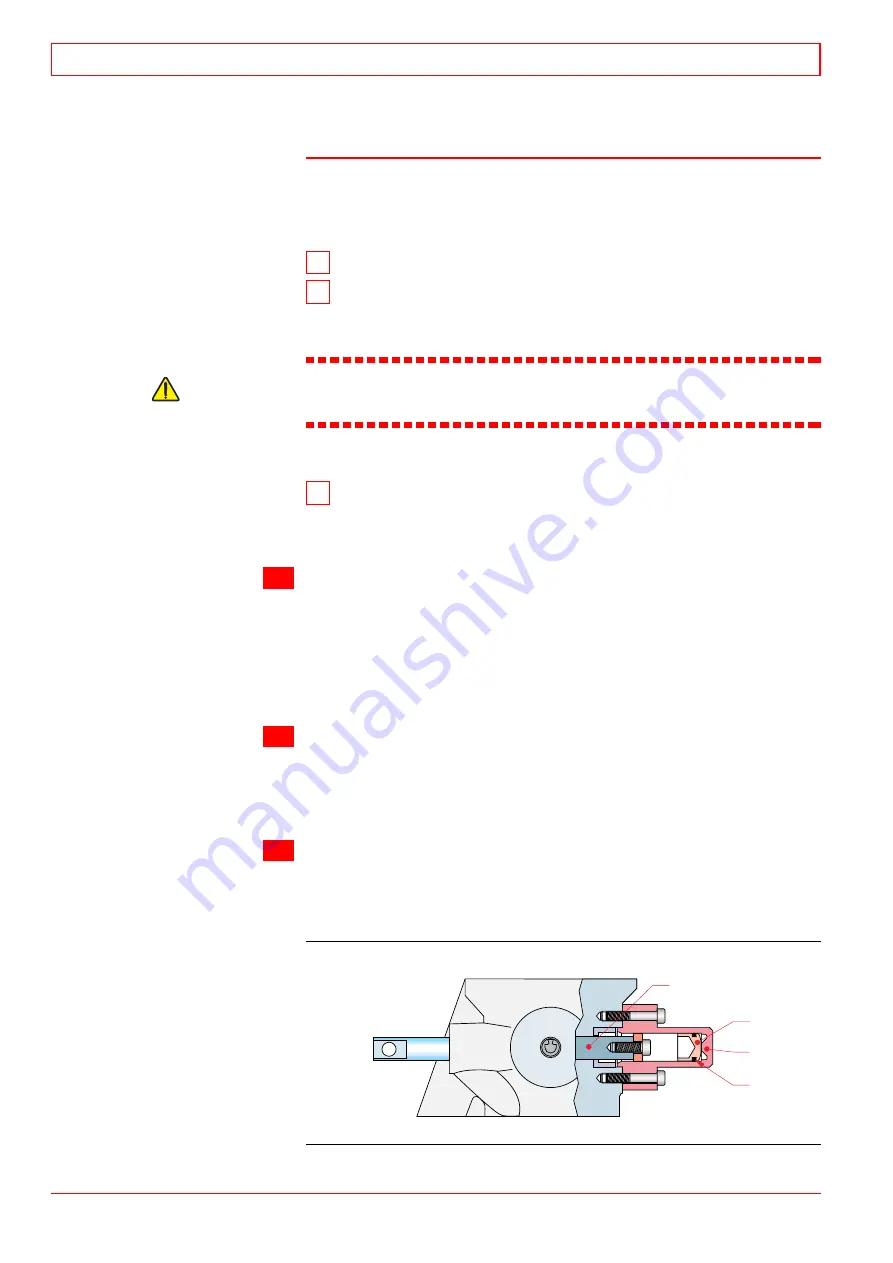

Electro-pneumatic overspeed trip device

3

2

1

1. Fuel rack

2. Piston

3. Cylinder

4. Slide ring

4

Fig 22-2

4016049601

22

Control Mechanism

32-200636-01

22 - 4

WÄRTSILÄ 32

Summary of Contents for PAAE051728

Page 4: ......

Page 18: ...Appendix B Welding Precautions 200640 00 6...

Page 26: ...01 Main Data Operating Data and General Design 32 200634 01 01 8 W RTSIL 32...

Page 60: ...Appendix A Environmental Hazards 200507 02A 10...

Page 68: ...Page 7 7 Document No 4V92A0645 Rev j...

Page 84: ...03 Start Stop and Operation 32 200402 04 03 12 W RTSIL 32...

Page 98: ...04 Maintenance Schedule 32 200623 01 04 14 W RTSIL 32...

Page 154: ...07 Tightening Torques and Use of Hydraulic Tools 32 200643 01 07 30 W RTSIL 32...

Page 162: ...08 Operating Troubles Emergency Operation 32 200402 01 08 8 W RTSIL 32...

Page 164: ...Specific Installation Data 2005 01 09 2...

Page 178: ...10 Engine Block with Bearings Oil Sump and Cylinder Liner 32 200150 10 14 W RTSIL 32 34SG...

Page 216: ...Appendix A Testing of cylinder tightness 32 200142 A 4 W rtsil 20 32 34...

Page 226: ...13 Camshaft Driving Gear 32 200546 02 13 10 W RTSIL 32...

Page 254: ...15 Turbocharging and Air Cooling 32 200549 10 15 20 W RTSIL 32...

Page 274: ...16 Injection System 32 200627 01 16 20 W RTSIL 32...

Page 280: ...Fuel System 32 200508 07 17 6 W RTSIL 32...

Page 314: ...19 Cooling Water System 32 200050 19 14 W RTSIL 32...

Page 394: ...23 Instrumentation and Automation 32 200115 II 23 60 W RTSIL 32...