Page 38

VP-X Installation and Operating Manual

Rev. D (August 5, 2020)

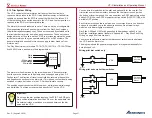

5.19a Pitch Trim Wiring

The trim wires are grouped together by trim function, and shown on the Load

Planning worksheet. They are separated from each other by number, but are

physically located next to each other on the connector. Each trim servo has

five wires: two for motor power, and three for position feedback.

Pitch Trim

Function

VP-X Pin

I/O

+2.5 reference voltage (wht/blu)

J1-8

O

Ground (wht/org)

J1-9

--

Position feedback (wht/grn)

J1-10

I

Trim motor (wht)

J1-11 (connect either way)

O

Trim motor (wht)

J1-12 (connect either way)

O

Pitch Trim Up switch input

J2-18

I

Pitch Trim Down switch input

J2-19

I

Connect the wires for the pitch trim system as follows, if installed:

•

Run the 5-conductor wire (five wires bundles together) to the trim

motor. The colors on the wiring harness match the colors on a Ray

Allen sensor and can be connected color to color.

Note: in some aircraft, it is desirable to provide a connector near the

elevator trim servo. A popular method is to crimp d-sub connector

terminals (machined barrel, mil-spec) to the servo wires and to the

wiring harness. First, slip a piece of large heat shrink tubing over the

wiring harness and move aside for later. Then, connect the terminals

on each wire pair and seal with heat shrink tubing, which insulates as

well as provides a secure connection. Be sure to offset each terminal

so that the bundle doesn’t get too big. Cover the bundle of wires with

the large heat shrink tubing.

• Connect the switch input pins to the trim switch (pilot and co-pilot).

Connect the other side of the switch to ground.

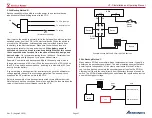

5.19b Roll Trim Wiring

The trim wires are grouped together by trim function, and shown on the Load

Planning worksheet. They are separated from each other by number, but are

physically located next to each other on the connector. Each trim servo has

five wires: two for motor power, and three for position feedback.

Roll Trim

Function

VP-X Pin

I/O

+2.5 reference voltage (wht/blu)

J1-3

O

Ground (wht/org)

J1-4

--

Position feedback (wht/grn)

J1-5

I

Trim motor (wht)

J1-6 (connect either way)

O

Trim motor (wht)

J1-7 (connect either way)

O

Roll Trim Left switch input

J2-16

I

Roll Trim Right switch input

J2-17

I

Connect the wires for the roll trim system as follows, if installed:

•

Run the 5-conductor wire (five wires bundled together) to the trim

motor. The colors on the wiring harness match the colors on a Ray

Allen sensor and can be connected color to color.

• Connect the switch input pins to the trim switch (pilot and co-pilot).

Connect the other side of the switch to ground.

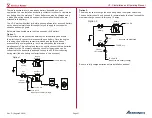

5.19c TruTrak Auto Trim Module

Follow the diagram below if installing the TruTrak auto trim module. The

diagram is for both 14 volt and 28 volt systems.

Ray Allen

Trim Servo

TruTrak

Pitch Servo

VP-X contols pitch trim when AP is off, TT auto trim controls pitch trim when AP is ON.

Pitch trim motor power

J1, pins 11 & 12

8

11

J1-11

J1-12

13

1

12

Autopilot power

out (5 amp)

Power to roll servo and AP head

10

9

VP-X

TruTrak

Auto

Trim

white

white

TruTrak Auto Trim Module Wiring 14 & 28 volt

Other connections on each device not shown.