Page 60

VP-X Installation and Operating Manual

Rev. D (August 5, 2020)

Motor

polarity

Standard/Inverted. Press the Up or Down buttons, and the

flaps should move in the appropriate direction. If not, change

the polarity until the flaps run in the correct direction. Press

Update

.

Once the motor direction is correct,

verify the flap switch

is wired correctly

by moving the flaps using the flap switch

(note: press

Update

button to save settings before using flap

switch)

Slow

Retract

When this feature is enabled, the flaps retract at

approximately 50% slower speed than normal while the

engine RPM is above

the configured RPM limit.

Flap Reflex Midpoint 1 must be set, and flaps must be set to “Position”

as described above. Midpoint 1 position should be set to the

neutral position, and UP should be set to the reflex position,

as described below. See

“10.5 Trim and flap operation”

more details.

Continuous

Flaps

Allows you to command a further flap down position before

the flaps reach the next stop. If enabled, you can bump the

flap down switch while the flaps are moving down and it will

continue to the next down position. Must be used with flaps in

“Position.”

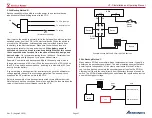

1. Read position here

2. Enter position here

Reading and Entering Flap Position on the VP-X Configurator

Note

The Up/Dn and midpoint limits only need to be set if a position

sensor is installed.

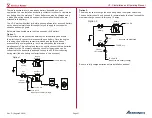

Up limit

Run the flaps all the way up using the Up soft key. Note

the number that shows the flap position (should be on the

screen, between 0 and 255). We recommend setting it a few

numbers short of the actual limit to allow for position slop.

Midpoint 1/2

Allows you to set intermediate flap stops. These are disabled

when the flap control is set to Momentary. Disregard for now.

Note: if these are set to non-zero values, they must be in

numerical order consistent with the up and down limits or an

error occurs during save.

Down limit

Run the flaps all the way down (or the desired end point)

using the Down soft key. Note the number that shows the

flap position (shown on the screen, between 0 and 255). We

recommend setting it a few numbers short of the actual limit

to allow for position slop.

Note on up and down limits:

Make sure the limit value (the number 0 - 255 corresponding

to the position) is set before or at the point of the physical limit.

For example, if the down limit value is set to 0, but the furthest it

goes is down to 8, then it will never reach zero and continue to

drive the motor in anticipation of reaching zero. The flap circuit

will reach the max run time of 45 seconds and then the circuit

will fault.