6-20

Valco Cincinnati, Inc.

Section 6 - Customize the Settings

MC091 - VCX OT-120 FlexosealPro 2 - Corrugated

3.

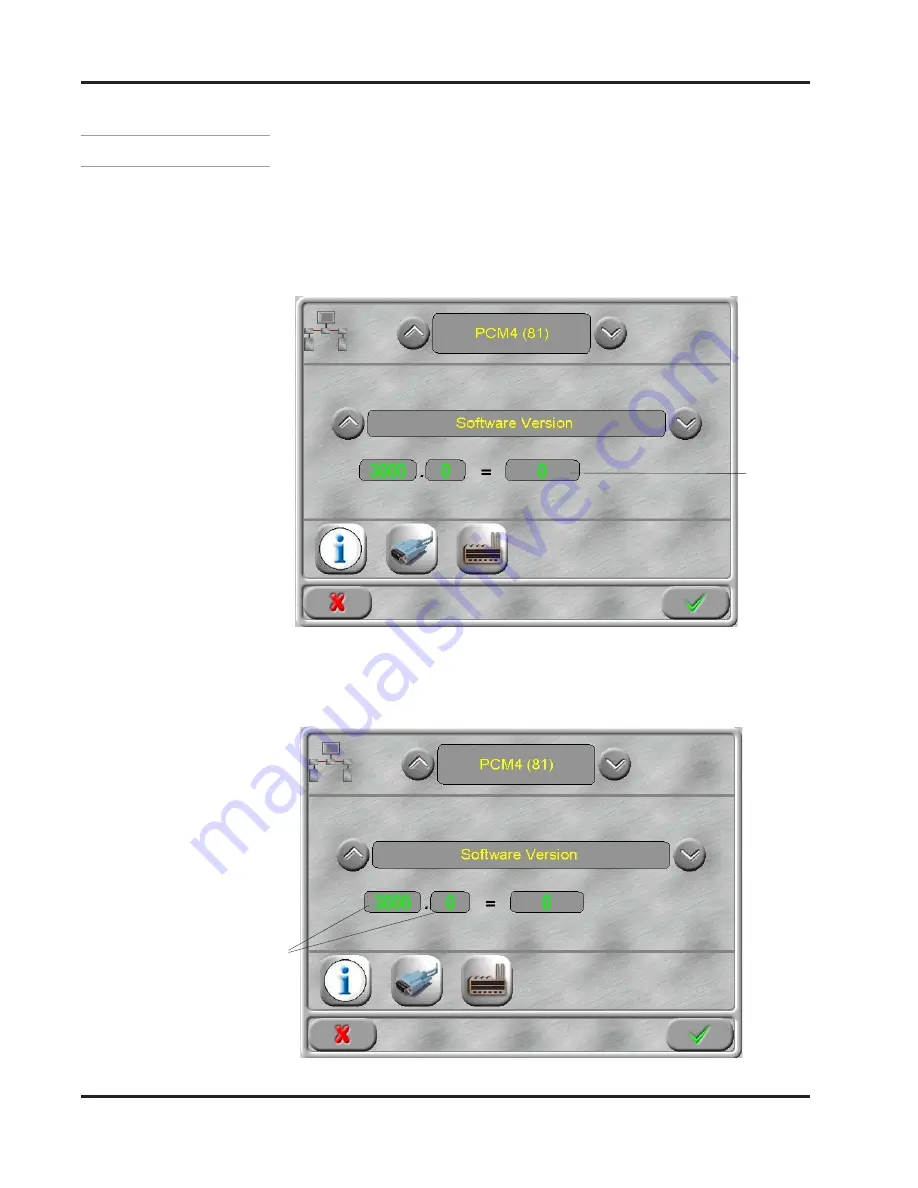

On the CAN Device Configuration Screen, use one of the

following methods to access the parameters:

Method 1:

-Enter an MCP parameter number in the Edit Field. The other

fields will be filled out with the applicable data to this specific

parameter.

Access Parameters - Continued

-Enter two “new” numbers in the Dual Edit Fields.

Method 2:

Figure 6-34. CAN Device Configuration Screen

Parameter

Number

Edit Field

Figure 6-35. CAN Device Configuration Screen

Dual Edit Fields