Operating Instructions

Bedienungsanleitung

Manuel d‘utilisation

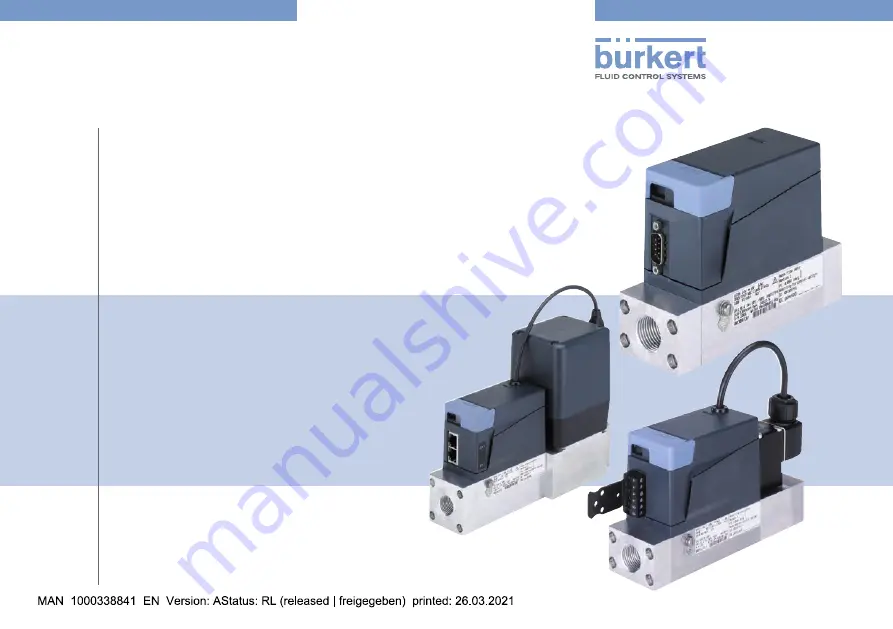

Type 8745

Industrial Ethernet

Analogue

Mass Flow Meter (MFM) / Mass Flow Controller (MFC)

Massendurchflussmesser (MFM) / Massendurchflussregler (MFC)

Débitmètre massique (MFM) / Régulateur de débit massique (MFC)