Description of Appropriate Use

This device is designed for laser cutting and engraving in an office, laboratory, workshop or light duty

manufacturing environment. Materials to be processed must fit completely inside the system for proper operation.

CAUTION:

This device is not designed, tested, intended or authorized for use in any medical applications,

surgical applications, medical device manufacturing or any similar procedure or process requiring approval,

testing or certification by the United States Food and Drug Administration or other similar governmental

entities.

General Safety

Use of the equipment in a manner other than described in this manual or failure to follow the operational

requirements and safety guidelines listed in this manual can result in injury to yourself and others and may cause

damage to the equipment and your facility.

EXPOSURE TO THE LASER BEAM MAY CAUSE PHYSICAL BURNS AND CAN CAUSE

SEVERE EYE DAMAGE.

Proper use and care of this system are essential to safe

operation. Use of controls or adjustments or performance of procedures other than those

specified herein may result in hazardous radiation exposure.

NEVER OPERATE THE LASER SYSTEM WITHOUT CONSTANT SUPERVISION OF THE

CUTTING AND ENGRAVING PROCESS.

Exposure to the laser beam may cause ignition

of combustible materials which can lead to a fire. A properly maintained fire extinguisher

should be kept on hand at all times.

NEVER LEAVE MATERIALS IN THE LASER SYSTEM AFTER LASER PROCESSING

HAS FINISHED.

Always remove all material including scrap material from the machine after

use. Scrap material left in the laser system including materials that collect in the removable

cutting table can be a fire hazard. It is also recommended you allow scrap materials to

cool prior to leaving the work area. A properly maintained fire extinguisher should be

kept on hand at all times.

A PROPERLY CONFIGURED, INSTALLED, MAINTAINED AND OPERATIONAL

PARTICULATE AND FUME EXHAUST SYSTEM IS MANDATORY WHEN OPERATING

THE LASER SYSTEM.

Fumes and smoke from the engraving process must be extracted

from the laser system and f ilter ed or exhausted outside.

SOME MATERIALS, WHEN ENGRAVED OR CUT WITH A LASER, CAN PRODUCE

TOXIC AND CORROSIVE FUMES.

We recommend that you obtain the Material Safety

Data Sheet (MSDS) from the manufacturer of every material you intent to process in the

laser system. The MSDS discloses all of the hazards when handling or processing a

particular material.

DISCONTINUE

processing any material that causes chemical

deterioration of the laser system such as rust, metal etching or pitting, peeling paint, etc.

Damage to the laser system from corrosive fumes is

NOT

covered under warranty.

DO NOT ATTEMPT TO MOVE OR LIFT THIS SYSTEM ALONE.

Obtain the assistance

o f additional people when lifting or carrying (secure motion system and doors before

lifting). Injury may occur if improper lifting techniques are used or the system is dropped.

9

Summary of Contents for PLS4.75

Page 1: ...PLS User Guide PLS4 75 PLS6 75 PLS6 150D PLS6MW www ulsinc com Revision August 2012...

Page 5: ...Chapter 1 Specifications 5...

Page 8: ...Chapter 2 Safety 8...

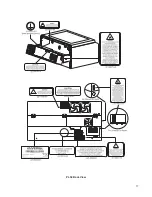

Page 14: ...Tamper Proof Labels Safety Labels...

Page 15: ...ULS Fiber Laser Cartridge Labels 15...

Page 16: ......

Page 17: ...PLS4 Back View 17...

Page 18: ...PLS6 Front View 18...

Page 19: ......

Page 22: ...Chapter 3 Installation 22...

Page 40: ......

Page 48: ...Chapter 4 Operation 48...

Page 83: ...Chapter 5 Accessories 83...

Page 99: ...Example Connection for PNP mode Example Connection for NPN mode 99...

Page 111: ...Chapter 6 Maintenance 111...

Page 119: ...www ulsinc com...