Exhaust System (User Supplied)

1. We recommend you consult with a licensed contractor to meet local safety and building code

requirements.

2. The exhaust system must be capable of supplying a minimum of

•

PLS4.75 - 250 CFM (cubic feet per minute) of airflow while under a load of 6 inches of static

pressure (850m

3

/hr at 1.5kPa).

•

PLS6.75 and PLS6.150D - 500 CFM (cubic feet per minute) of airflow while under a load of 6

inches of static pressure (850m

3

/hr at 1.5kPa).

2. Do not install forward incline, backward incline, in-line or ventilator fans because these types of air

handlers are inadequate and inappropriate for this type of installation. A high-pressure blower must be

used to meet minimum airflow requirements.

3. For personal safety and noise control, we recommend that the exhaust blower be mounted outside the

building.

4. Rigid tubing should be used for the majority of the connection between the blower and the laser system.

The tubing should be smooth-walled and have as few 90-degree bends as possible.

5. Install an exhaust gate to adjust airflow and to close off the exhaust when the laser is not in use. Place

this gate near the laser system within 5 to 10 feet (1.50 to 3.00 meters).

6. Use a short piece of industrial grade, wire-reinforced rubber tubing to connect each laser system exhaust

port to an exhaust gate and secure with a hose clamp. This will provide isolate exhaust blower vibrations

from your laser system.

7. Wire the exhaust blower electrically to a wall switch in the same room for easy ON/OFF control.

Note:

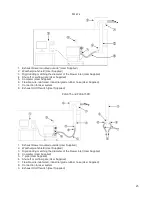

The following diagram shows a typical exhaust system layout. Use this as a guideline for proper

exhaust system installation. Although this diagram serves as an example, we recommend you consult with a

licensed contractor to meet local safety, environmental and building code requirements and to also calculate

the correct size blower required for your particular installation. Length of exhaust pipe, exhaust pipe diameter,

number of 90-degree angles and other restrictions must be calculated when determining the correct exhaust

blower unit. Installing an undersized or oversized blower is not only unsafe, but can also lead to excessive

wear and tear to the laser system and premature failure.

24

Summary of Contents for PLS4.75

Page 1: ...PLS User Guide PLS4 75 PLS6 75 PLS6 150D PLS6MW www ulsinc com Revision August 2012...

Page 5: ...Chapter 1 Specifications 5...

Page 8: ...Chapter 2 Safety 8...

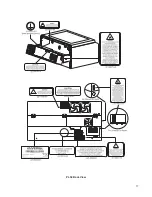

Page 14: ...Tamper Proof Labels Safety Labels...

Page 15: ...ULS Fiber Laser Cartridge Labels 15...

Page 16: ......

Page 17: ...PLS4 Back View 17...

Page 18: ...PLS6 Front View 18...

Page 19: ......

Page 22: ...Chapter 3 Installation 22...

Page 40: ......

Page 48: ...Chapter 4 Operation 48...

Page 83: ...Chapter 5 Accessories 83...

Page 99: ...Example Connection for PNP mode Example Connection for NPN mode 99...

Page 111: ...Chapter 6 Maintenance 111...

Page 119: ...www ulsinc com...