Air Flow Setting Guidelines

As a rule of thumb the flow rate should be set as low as possible for the application especially when using

gas, start with low flow and adjust upward until the desired result such as suppression of flame up.

Maintenance

The components of the Manual Air Assist are maintenance free. However, use of air assist may cause the

interior of the laser system to become dirty faster. Keep you laser system clean for best performance.

Computer Controlled Air Assist

Computer Controlled Air Assist is employed with a backsweep or cone to control air or gas flow onto the material

during laser material processing. This feature also provides compressed air to the optics (mirrors and lenses) in

the system reducing contamination. Air/Gas assist aids in removing smoke and debris from the laser processing

area and directing it to the exhaust. It also helps reduce the heat affected zone in the material being processed

and helps to prevent flame up when processing certain materials. Use of this system requires a supply of 50 PSI

max pressure and 2.0 cfm free air flow (3.2 bar and 3.2 cubic meters/hour), clean, dry oil free compressed air or

gas. Air can be provided by the ULS computer Controlled Compressed Air Unit. Gas, such as nitrogen or carbon

dioxide, can be supplied from pressurized gas tanks with a pressure regulator to keep pressure below 60 PSI.

That can be procured from local industrial gas vendors. Use of cone vs. backsweep is dependent on the

application. The backsweep fitting is geared more toward engraving applications and the cone is geared more

toward cutting applications.

CAUTION:

Do not use flammable or corrosive gases as this can result in injury or fire.

NOTE:

Air Assist can decrease frequency of required cleaning for the optics, but will not decrease the need

for maintenance as a whole.

Solenoids are employed to control the air flow automatically as a laser job is processed. Use of air assist is

programmed through the printer driver when a laser job is created. Air or gas can be selected independently

for raster, vector marking and vector cutting using the materials database tab of the printer driver and can be

selected independently per color in the color table using the manual printer driver tab. Flow rate can be

selected in 25% increments.

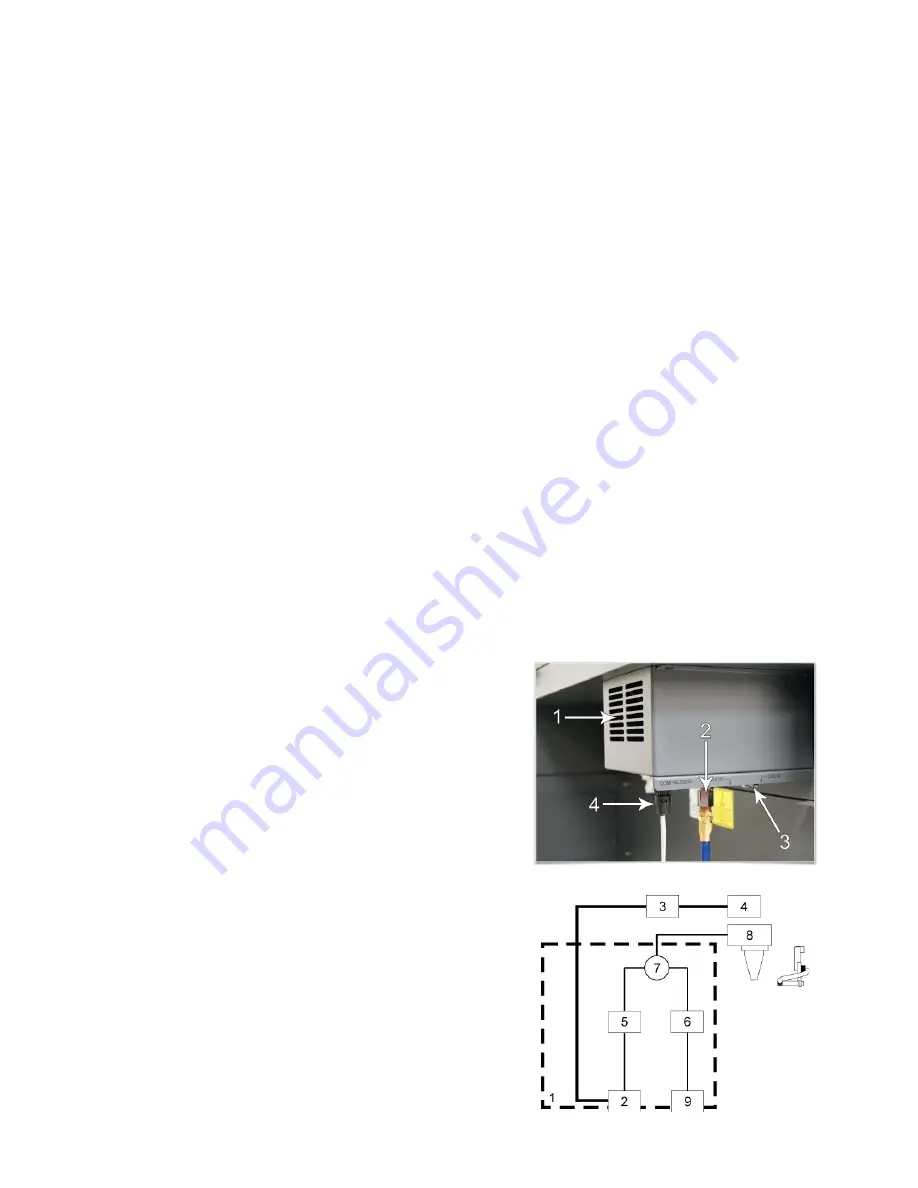

Connections to the Computer Controlled Air Assist

•

Compressed Air from the ULS computer Controlled

Compressed Air Unit connects to the fitting labeled

“air in” (2).

•

Gas supply is connected to the fitting labeled “gas in”

(3). The quick fitting used to connect the gas supply

accepts a ¼ NPT fitting.

•

The control cable for the ULS computer Controlled

Compressed Air Unit is attached to the connector

labeled compressor (4).

Functions of the Computer Controlled Air Assist

The control box (1) (represented by the dotted lines) directs the

compressed air source to the optics protection path and also to

the cone. The optics protection path is a direct path from the

entry point of the compressed air source (2) to the #2 mirror (3)

and #3 mirror (4). The air supply for the cone or backsweep

comes from either the AIR valve (5) or the GAS valve (6), then

85

Summary of Contents for PLS4.75

Page 1: ...PLS User Guide PLS4 75 PLS6 75 PLS6 150D PLS6MW www ulsinc com Revision August 2012...

Page 5: ...Chapter 1 Specifications 5...

Page 8: ...Chapter 2 Safety 8...

Page 14: ...Tamper Proof Labels Safety Labels...

Page 15: ...ULS Fiber Laser Cartridge Labels 15...

Page 16: ......

Page 17: ...PLS4 Back View 17...

Page 18: ...PLS6 Front View 18...

Page 19: ......

Page 22: ...Chapter 3 Installation 22...

Page 40: ......

Page 48: ...Chapter 4 Operation 48...

Page 83: ...Chapter 5 Accessories 83...

Page 99: ...Example Connection for PNP mode Example Connection for NPN mode 99...

Page 111: ...Chapter 6 Maintenance 111...

Page 119: ...www ulsinc com...