Instruction manual for MH & MH+M

11

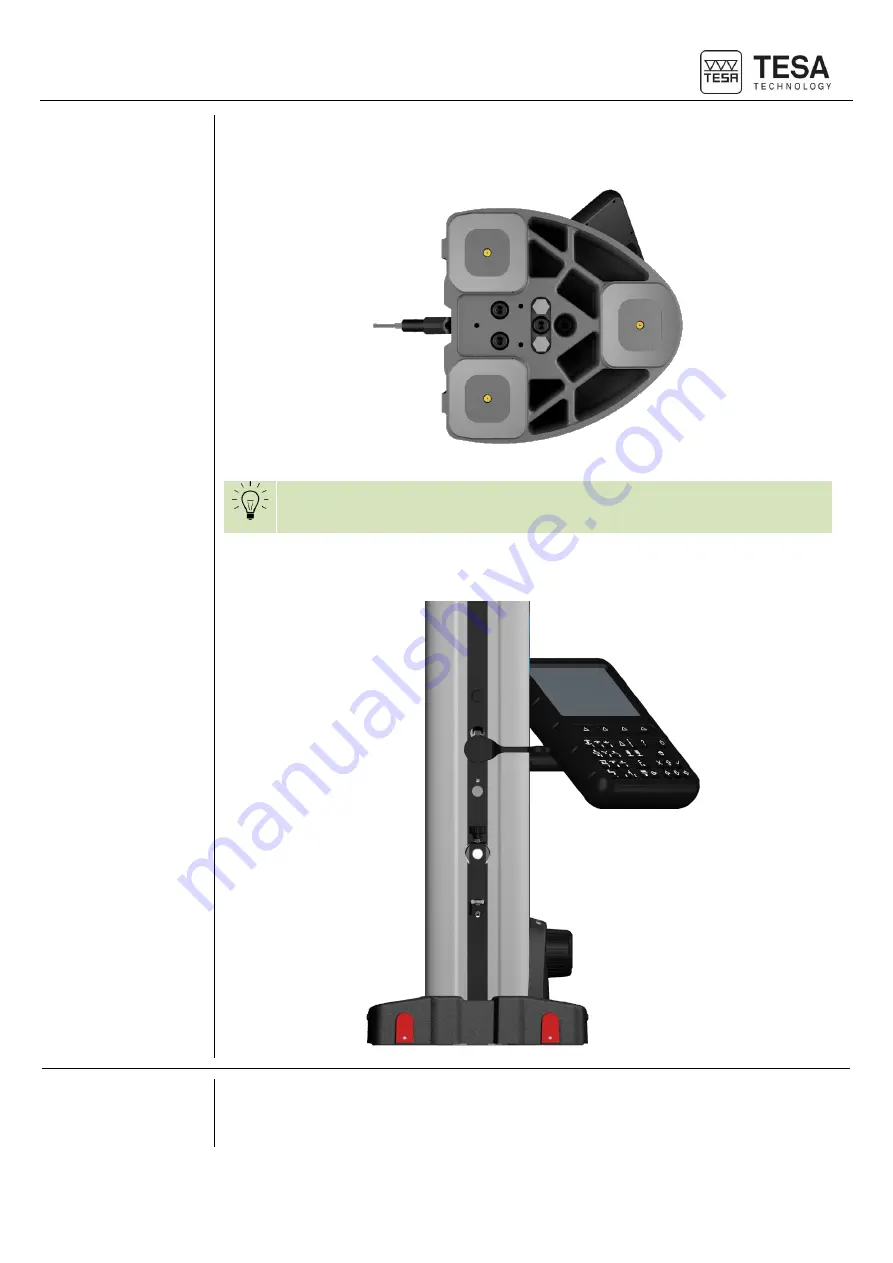

2.2 Instrument base

The base is chemically nickel-plated in order to make it very resistant to corrosion. Its lower

face, which has been machined to ensure that is rigorously flat, includes three finely-machined

support lugs (air bearings) that guarantee the stability of the height gauge.

These lugs form a large surface so that any grooves or other similar

irregularities on the granite table can be easily cleared.

The faces (9) defined by the red zones in the schema below are specially designed to support

the instrument against a parallel gauge block or for guiding it along such a block.

2.3 Air cushion

The air cushion, which is generated by an integrated electric pump, allows the height gauge to

be easily moved on the granite table. The height gauge can then be moved effortlessly and

any wear created by friction is avoided.