83-000-016 Rev. F

WARRANTY

This TDK-Lambda Americas Inc. product is warranted against defects in materials and workmanship for

a period of five years from date of shipment. During the warranty period, TDK-Lambda Americas Inc.

will, at it’s option, either repair or replace products which prove to be defective.

LIMITATION OF WARRANTY

The warranty shall not apply to defects resulting from improper or inadequate usage or maintenance by

the buyer, buyer supplied products or interfacing. The warranty shall not apply to defects resulting from

unauthorized modifications, or from operation exceeding the environmental specifications of the

product, or if the QA seal has been removed or altered by anyone other than TDK-Lambda Americas

Inc. authorized personnel. TDK-Lambda Americas Inc. does not warrant the buyer’s circuitry or

malfunctions of TDK-Lambda Americas Inc. products resulting from the buyer’s circuitry. Furthermore,

TDK-Lambda Americas Inc. does not warrant any damage occurring as a result of the buyer’s circuitry

or the buyer’s - supplied products. THIS LIMITED WARRANTY IS IN LIEU OF, AND TDK-LAMBDA

AMERICAS INC DISCLAIMS AND EXCLUDES, ALL OTHER WARRANTIES, STATUTORY, EXPRESS

OR IMPLIED, INCLUDING, WITHOUT LIMITATION, ANY WARRANTY OF MERCHANTABILITY OR

FITNESS FOR A PARTICULAR PURPOSE, OR OF CONFORMITY TO MODELS OR SAMPLES.

WARRANTY SERVICE

This product must be returned to an authorized TDK-Lambda Americas Inc. service facility for repairs or

other warranty service. For products returned to TDK-Lambda Americas Inc. for warranty service, the

buyer shall prepay shipping charges to TDK-Lambda Americas Inc. If the unit is covered under the

foregoing warranty then TDK-Lambda Americas Inc. shall pay the shipping charges to return the

product to the buyer. Refer to Section 3.11 for repackaging for shipment.

DISCLAIMER

The information contained in this document is subject to change without notice. TDK-Lambda Americas

Inc. shall not be liable for errors contained in this document or for incidental or consequential damages

in connection with the furnishing, performance or use of this material. No part of this document may be

photocopied, reproduced or translated into another language without the prior written consent of TDK-

Lambda Americas Inc.

TRADEMARK INFORMATION

Genesys

™

power supply is a trademark of TDK-Lambda Americas Inc.

Microsoft

™

and Windows

™

are trademarks of Microsoft Corporation.

THE FCC WANTS YOU TO KNOW

This equipment has been tested and found to comply with the limits for a Class A digital device,

pursuant to Part 15 of the FCC rules. These limits are designed to provide reasonable protection

against harmful interference when the equipment is operated in a commercial environment.

This equipment generates, uses and can radiate radio frequency energy and, if not installed and used in

accordance with the instructions, may cause harmful interference to radio communications.

Operation of this equipment in a residential area is likely to cause harmful interference, in which case

the user will be required to correct the interference at his own expense.

FCC WARNING

Modifications not expressly approved by manufacturer could void the user authority to operate the

equipment under FCC Rules.

1

Summary of Contents for GENESYS 10KW

Page 2: ......

Page 3: ......

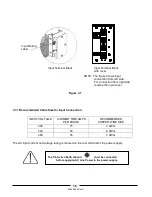

Page 31: ...83 530 000 Rev G 28 Fig 4 2 Rear panel connections and controls...