123

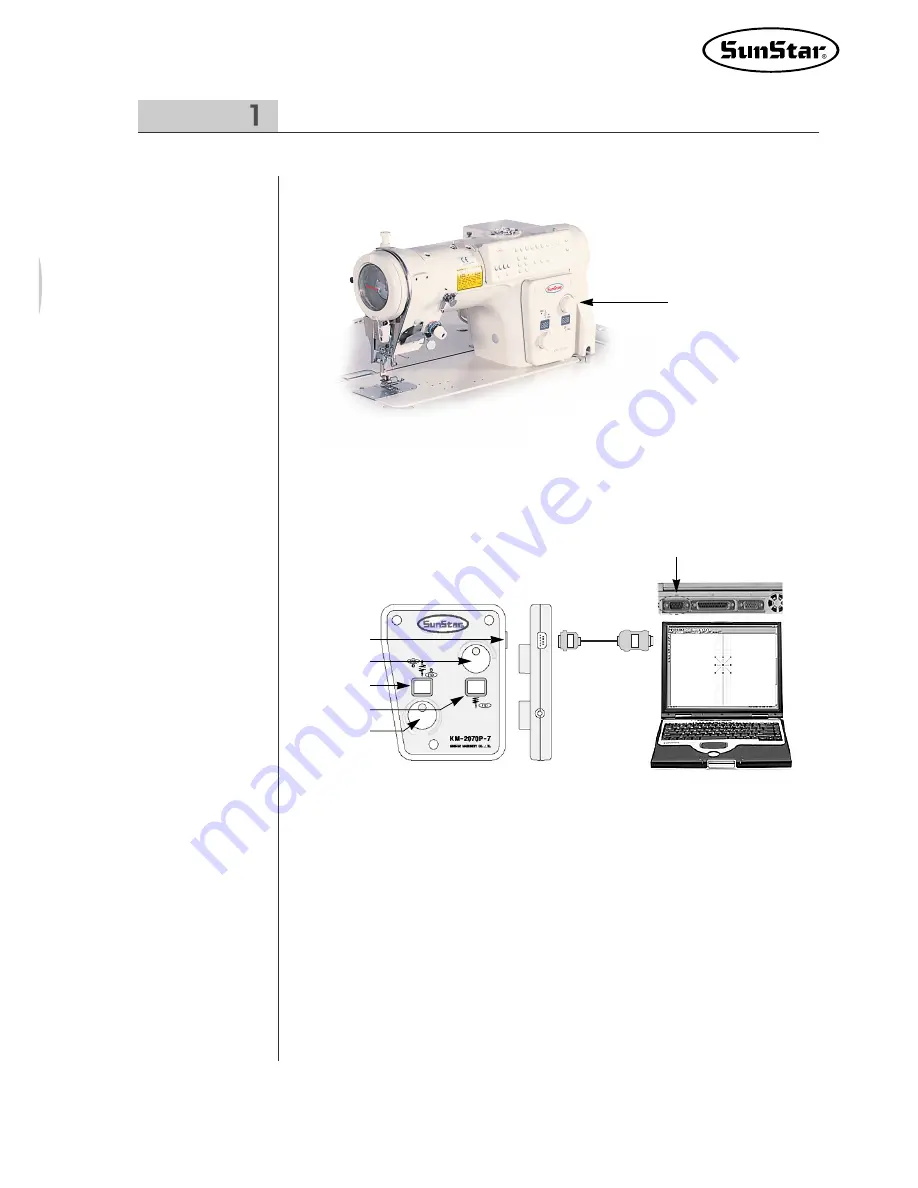

PC and KM-2070P connection configuration

Connect the serial transmission cable to serial transmission port connection jack

and to serial transmission cable connection port jack of KM-2070P dial control

box.

[ Serial cable connection configuration ]

Dial control box

Side

Serial transmission

cable connection port

Feed control dial

Condenser control

value display

Feed control value

display

Condenser control

dial

Serial cable

Serial transmission port

Dial control box

Computer

Computer backside

KM-2070P-7

Summary of Contents for SSP-WE/3.5

Page 1: ...SSP WE 3 5 IInstruction M Manual SSP WE 3 5 MEE 070418 ...

Page 2: ......

Page 6: ...6 Before Using Check the followings prior to setting up the program and components ...

Page 18: ...18 Configuration of Program Function ...

Page 31: ...31 Data Configuration ...

Page 37: ...37 Create Data ...

Page 103: ...103 Circle point setting Cross point setting ...

Page 142: ...142 ...

Page 147: ...147 ...