6-5

Routine Maintenance

Operator Manual

122993-622

•

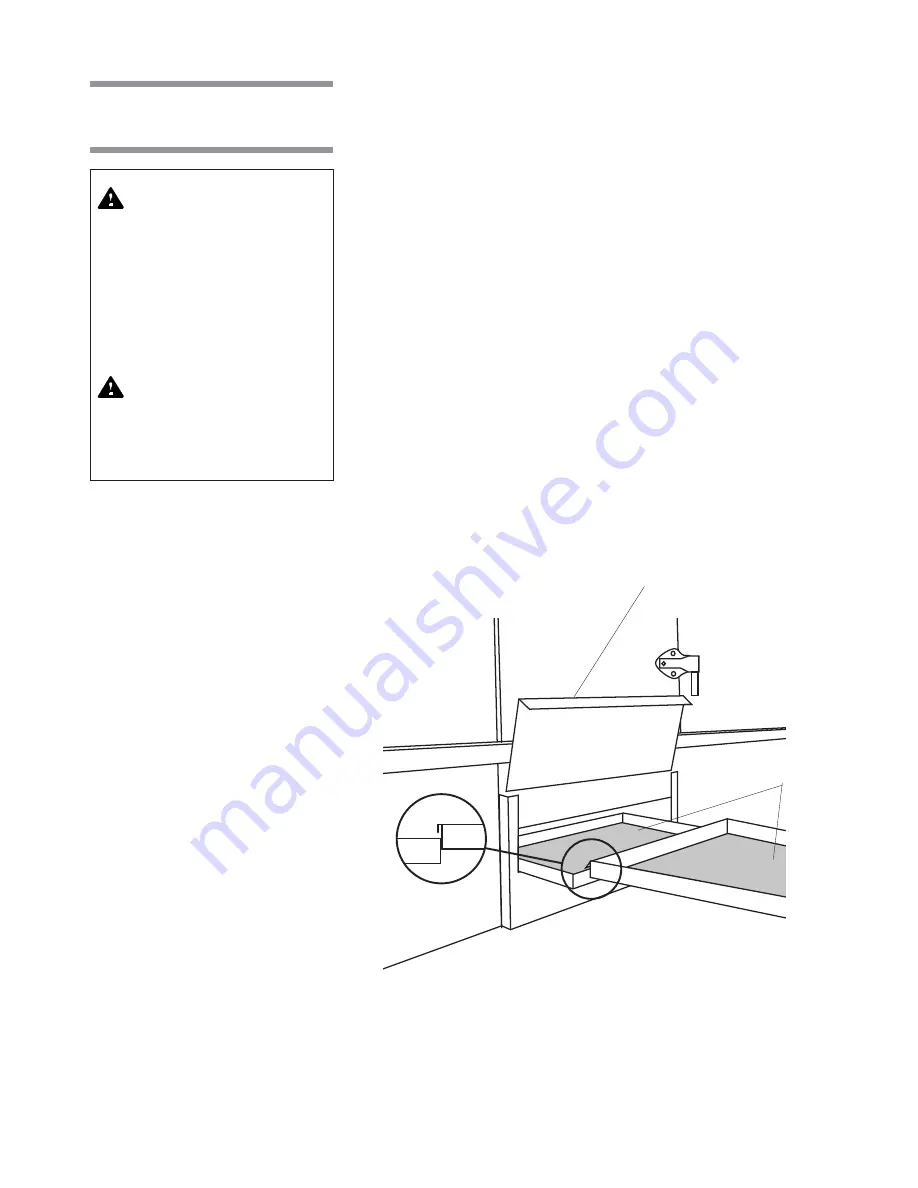

Chamber Solution Screen

NOTE: Clean chamber solution screens while they are still wet, before foreign

matter dries.

1.

Lock disconnect switch in

OFF

position and close building supply valves.

2.

Remove access panel from side of cabinet section.

3.

Slide screens out of chamber and separate screen pieces as they appear

(see Figure 6-1).

4.

Remove any debris from screens.

5.

Slide screens back into chamber. Ensure screen pieces are hooked

together (see Figure 6-1).

6.

Replace access panel and re-energize washer utilities.

•

Garb-el (Option)

After each day of use, run Garb-el for several minutes until both the feed hopper

and the grinding chamber are clear of waste material. This procedure flushes

out the sewer line.

In addition, wash down hopper interior using a few pails of water or a hose.

Disinfectants may be used. Ensure to use disinfectants that will not damage

metal or stainless steel.

WARNING – ELECTRICAL

SHOCK AND/OR BURN

HAZARD: Disconnect all

utilities to washer before

servicing. Do not service the

washer unless all utilities

have been properly locked

out. Always follow local

electrical safety-related

work practice standards.

WARNING – BURN HAZARD:

Before performing any ser-

vice on the unit, wait until

chamber and piping cool to

room temperature.

6.3 Daily Cleaning

Procedures

Figure 6-1. Two-Piece Solution Screen

Screen Access Panel

Chamber Solution

Screens