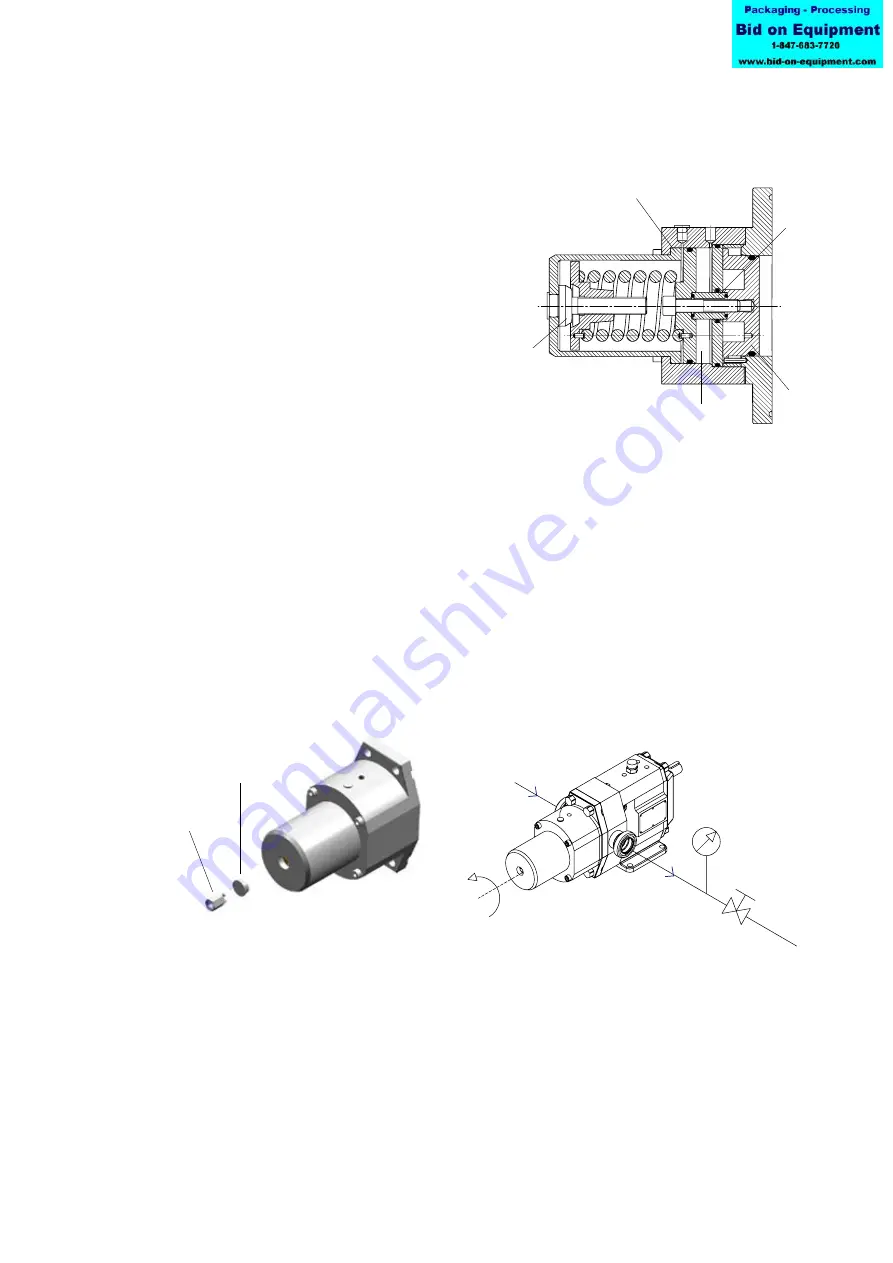

99

B

A

ii

C

D

A.0500.251 – IM-TL/13.00 EN (08/2009)

12.2.4 Setting and operating – Spring loaded and spring loaded - air lifted

Since the opening pressure of the relief valve is depending on the viscosity of the

pumped medium, the setting of the relief valve should be done while the pump is fitted

in the installation. To be able to do so there must be a pressure gauge installed as close as

possible to the pump discharge port and a valve must be foreseen in the discharge line to

adjust the discharge pressure.

To adjust the set-pressure of valve do as follows:

• Remove the plastic plug at the front of the valve

• Use the retainer tool to turn the adjusting screw counter-clockwise until the spring is

completely relieved

• Connect the pressure gauge to the discharge line and open the discharge valve

completely

• Start the pump

• Use the retainer tool to turn the adjusting screw clockwise until the maximum spring

setting is reached (the valve is blocked). While doing this, check on the pressure

gauge that the pressure does not rise above the maximum allowable pressure of the

pump.

Plastic plug

Retainer tool

Valve

adjusting

Pressure gauge

Valve

12.2.3.2 Spring loaded - air lifted with CIP/SIP valve function

Fig 6:

Safety relief valve –

Spring loaded - air lifted with CIP/SIP valve function

Fig. 6 shows the valve completely

opened. The pressure inside chamber

(ii) has forced the piston (C) and the

valve head (A) which is connected to

it to the left against the force of the

spring.

To operate the CIP/SIP valve function

chamber (ii) must be pressurized with

6 bar, which is the normal pressure

of air supply systems. This way it is

ensured that the valve is opening far

enough for CIP/SIP cleaning

purposes.

The pressure is acting on the CIP/

SIP valve piston (C). By doing that

the CIP/SIP valve piston (C) and the

valve head (A) which is connected to

it via the spacer sleeve (D) will move

against the force of the spring.

To resume the safety relief valve

function, cylinder (ii) must be

completely relieved.