24

A.0500.251 – IM-TL/13.00 EN (08/2009)

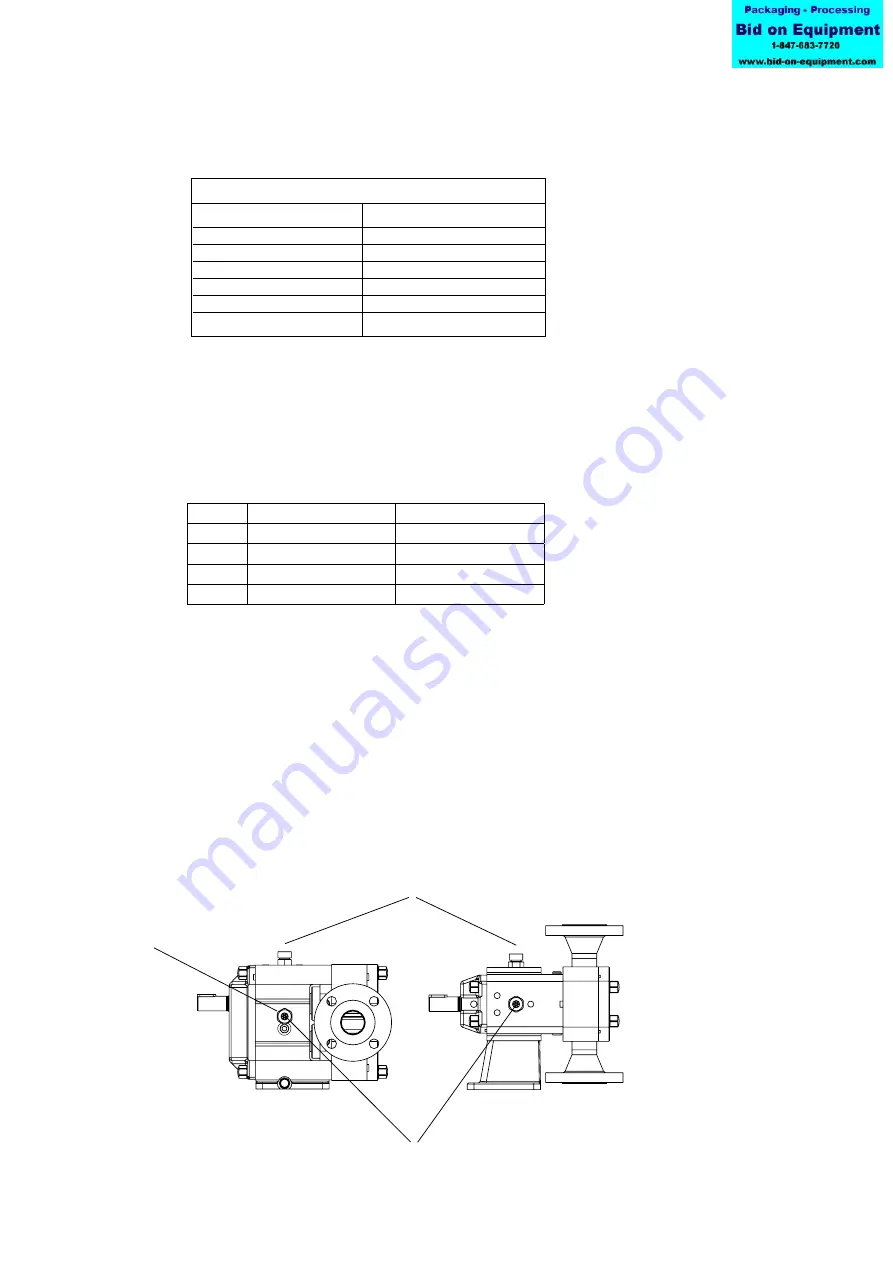

The oil level glass must

ALWAYS be installed in the

UPPER of the two threaded

holes provided in the gearbox.

Pump operating temperature

-20°C to +130°C

+130°C to 200°C

(-4°F to +266°F)

(+266°F to 392°F)

BP Energol GR - XP150

BP GRS15

Castrol Alpha SP150

Castrol Alpha SN150

Mobil Gear 629

Mobil Glycoyle 30

Shell Omala 150

Shell Tivela WA

Texaco Meropa 150

Texaco Synlube SAE90

Esso Spartan EP150

Esso IL1947

3.2 Lubricants

Pump

Horizontal connection

Vertical connection

TL1

0.23 lit

0.17 lit

TL2

0.37 lit

0.32 lit

TL3

1.20 lit

0.96 lit

TL4

2.24 lit

1.71 lit

Oil volume

After filling up oil, check the oil level in the oil level glas.

Air breather

Oil level glass

Vertical

Location of the oil level glass and the air breather

The pump will not be supplied pre-filled with oil therefore this table must be used to

select recommended oil.

Oil changing: Oil level must be checked with the pump static.

First change: After 150 hours of operation, thereafter every 3000 hours of operation.

Oil filling:

Fill with oil through the filler plug to the level indicated in the oil level

glass.

Recommended oils

Horizontal

When the pump is mounted in the horizontal position (e.g. the pipe joints are in the

horizontal plane) the oil level glass must ALWAYS be installed in the UPPER of the two

threaded holes provided in the gearbox. This will guarantee, on inspection, that the oil

level will reach the gearbox bearings. The lower hole is to be plugged with the standard

plug, position nr. 0915. The oil level glass is always installed as described above on

delivery from SPX Process Equipment.

If the customer, after delivery, decides to turn the pump “upside down” in order to have

the drive shaft in a different position, then the above instructions must be followed.