96

A.0500.251 – IM-TL/13.00 EN (08/2009)

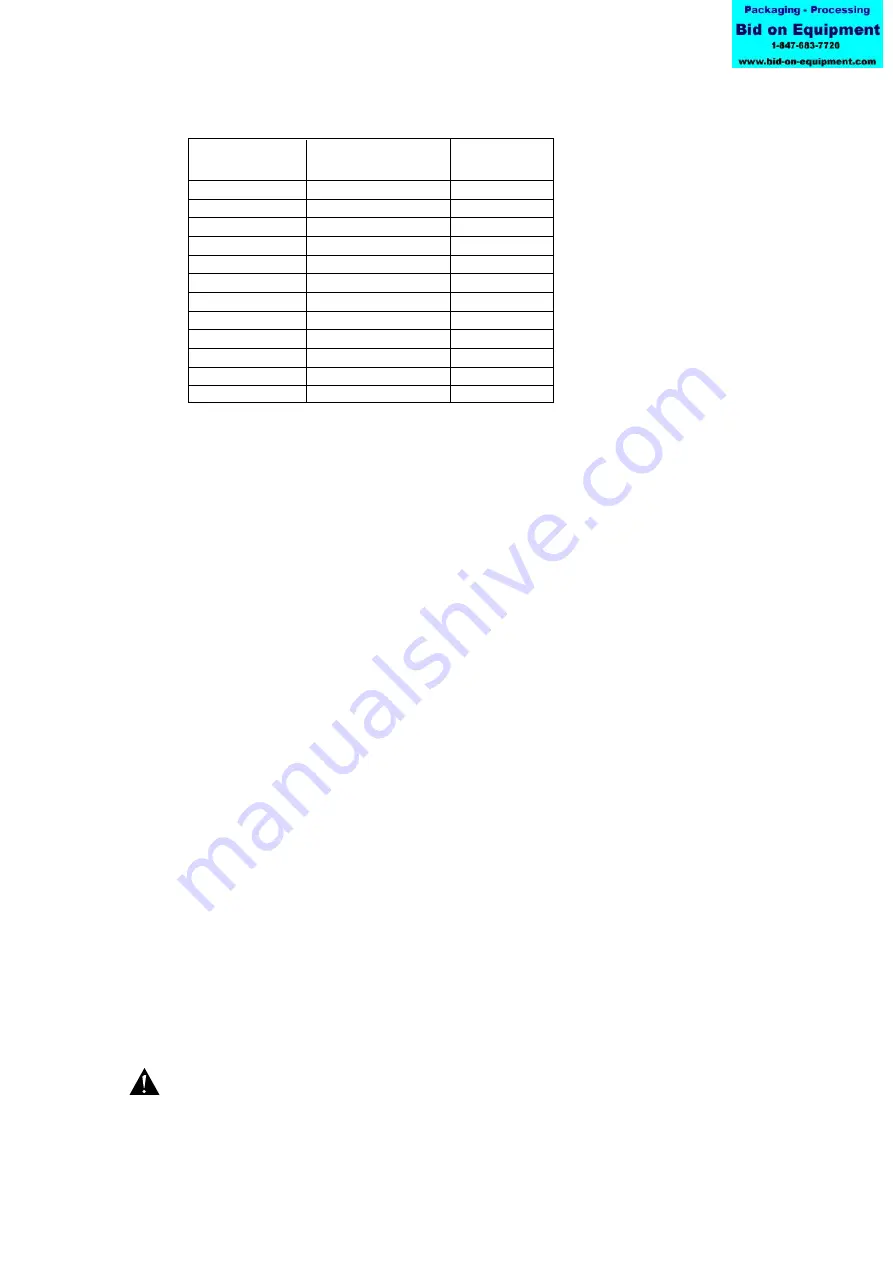

Following pressure limitations are applicable for TopLobe pumps

12.2.1 General description

Significant for all SPX Process Equipment safety relief valves is that the valve head is

built directly into the pump cover. In this way the valve is of the highest hygienic design

and easy to clean or check. The head has been designed to maximize the flow passage

section and to minimize pressure losses as well as allow particles to pass through. When

the valve head is opening, it creates a short cut between discharge and suction side of

the pump. On the valves equipped with air-lift function the valve head can be opened to

create a by-pass to reach the necessary flow-passage for CIP or SIP cleaning.

The valve head is covering part of the discharge side as well as the suction side of the

pump. It is also covering most of the front face of the rotors. The pressure distribution in

this area is depending on the properties of the pumped media. The differential pressure

on the pump is influencing the load that is acting on the valve head. The set value of the

spring or air pressure is balancing the valve head. The properties of the pumped media,

the design of the application as well as the process influences the load acting on the valve

head. These are the main reasons why the valve setting should not be done in the factory.

The setting of the valve should be carried out on site under proposed duty conditions for

which the pump and valve were selected.

When the differential pressure of the pump becomes higher than the valve settings, the

valve head will open. Due to the large size of the valve head, the full capacity of the

pump can pass through the valve from the discharge back to the suction side. With the

correct setting it is not possible to overpressure the pump under no circumstances.

If the pump is working against a closed discharge valve the medium circulates inside the

pump via the relief valve. The hydraulic power and the friction losses are transformed to

thermal energy and the temperature of this relatively small volume of circulating fluid

will rise if the pump continues to operate for an extended period of time. In severe cases

this may result in temperatures exceeding the operating limits of the pump or in

vaporization of the fluid, both of which should be avoided. For these reasons, the valve

should only be used as a safety relief valve and not as flow control valve.

When the valve is activated an unforeseen operating condition has occurred. The reason

for the system pressure increase should be investigated and corrected, as continuous

operation of the pump with the valve open is not allowable and may cause severe

damage to the pump.

Under no circumstances attempt should be made to dismantle a safety relief valve when

the spring pressure is not relieved, when it is still connected to a pressurized air supply or

is mounted on the pump while the pump is operating. Serious personal injury or pump

damage may occur.

Max differential

Max operating

pressure

pressure

Pump type

[bar]

[bar]

TL1/0039

22

25

TL1/0100

12

15

TL1/0139

7

10

TL2/0074

22

25

TL2/0234

12

15

TL2/0301

7

10

TL3/0234

22

25

TL3/0677

12

15

TL3/0953

7

10

TL4/0535

22

25

TL4/2316

12

15

TL4/3497

7

10