14

SECTION 6

TIMING AND SPRAY SETTINGS

6.1 PRECISION SPRAY CONTROL (PSC)

The PulsaJet® automatic spray nozzle is an electrically

-

activated hydraulic, atomizing nozzle. This nozzle sprays the

product in a controlled way using a PWM algorithm to control the sprayed amount without affecting the spray angle.

PWM is the fundamental control principle that allows a significant reduction in flow by regulating the relationship

between the on/off times that the nozzle operates.

Short pulses of on

-

time and longer pulses of off

-

time produce a spray pattern that appears continuous, but actually

reduces the overall flow delivered to the target surface. This provides better flow control with larger spray tips that

are less prone to clogging. The droplet size is affected by the pressure of the liquid. With PSC, the droplet size and

spray angle are independent of the liquid flow because the nozzle can work at the same liquid pressure for variable

liquid flows.

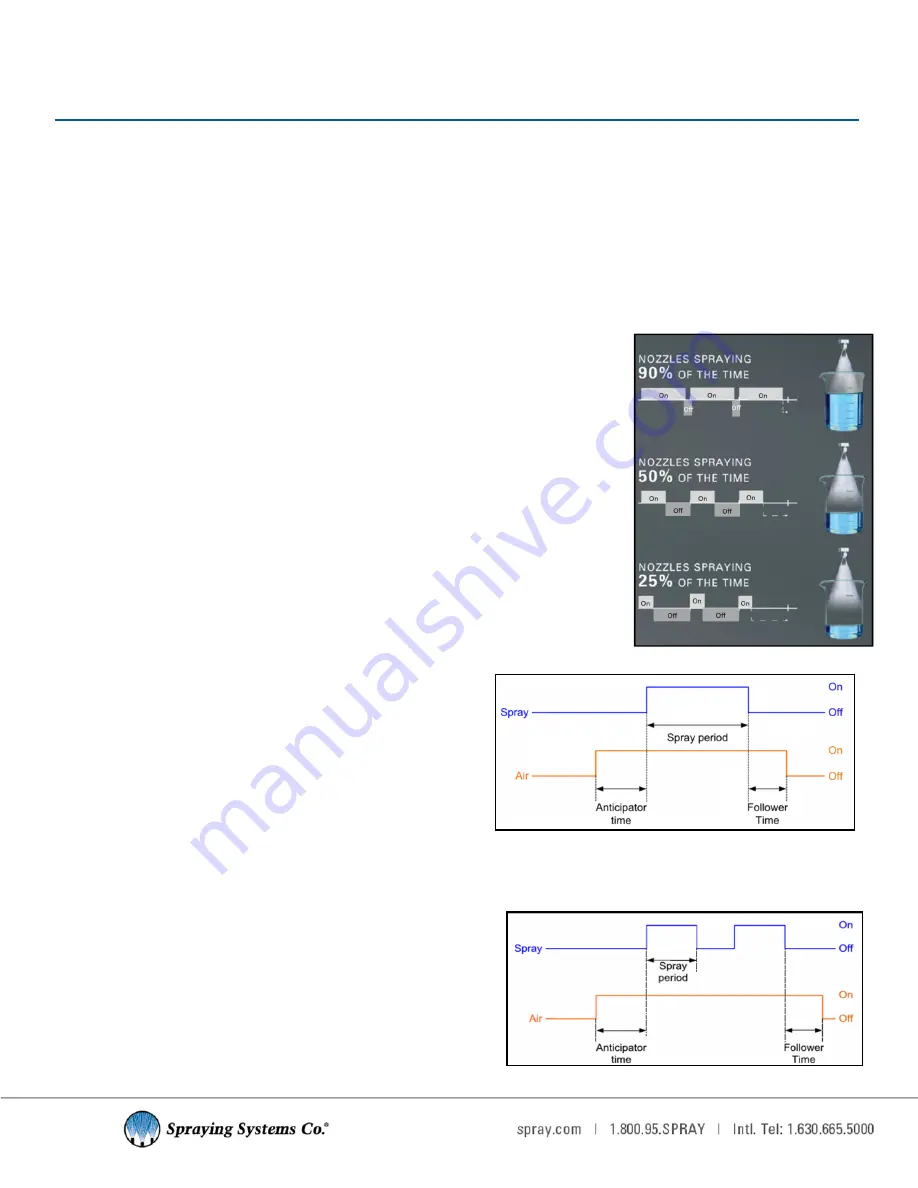

PSC involves switching the spray nozzle on and off repeatedly at a controlled rate,

called the modulating frequency. The modulating frequency is the number of times

the nozzle is switched on and off in one second and is measured in Hertz (Hz). If a

spray nozzle is switched on and off 10 times per second, the modulating frequency is

10 Hz. The time from when the nozzle turns on to the next time the nozzle turns on

is called the period, in this case 1/10th of a second.

Within a single period, the nozzle is switched on, then off. The time that the nozzle is

on, divided by the total time of the period, gives a percentage which is called the

duty cycle. For example, if the period is 0.10 seconds, and the nozzle is on for half of

that time, then the duty cycle is 50%. For the same period, if the nozzle is on for 0.08

seconds then the duty cycle is 80%. Therefore, at an 80% duty cycle, the flow will

theoretically be 80% of the maximum flow rate (= 100% flow rate) at a given

pressure for the nozzle. Using PSC, the flow rate for a spray application can be easily

controlled without the need to adjust the spray pressure or spray tip.

6.2 TIMING AND SPRAY OVERVIEW

ANTICIPATOR/FOLLOWER TIME

The system will start spraying when it receives a trigger signal

and stop when the trigger signal is removed.

If the system is equipped with an air atomizing nozzle, the

2850+ will switch the air output on before it starts spraying to

allow the spray pattern to develop fully. When the system stops

spraying, the air will continue for a short period after to

guarantee no large droplets can drip off of the nozzle. Max time

for both is 10 seconds.

Note:

The anticipator time must not be shorter than the start delay time set in the timing settings.

When a spray pattern is generated where the off time <

(anticipator time + follower time), the air output remains on for

the duration of this pattern.

Anticipator

-

Follower

Overlapping anticipator / follower sequence