CHAPTER 7. DISASSEMBLY AND ASSEMBLY

PN-T321/T322B

DISASSEMBLY AND ASSEMBLY

7 – 6

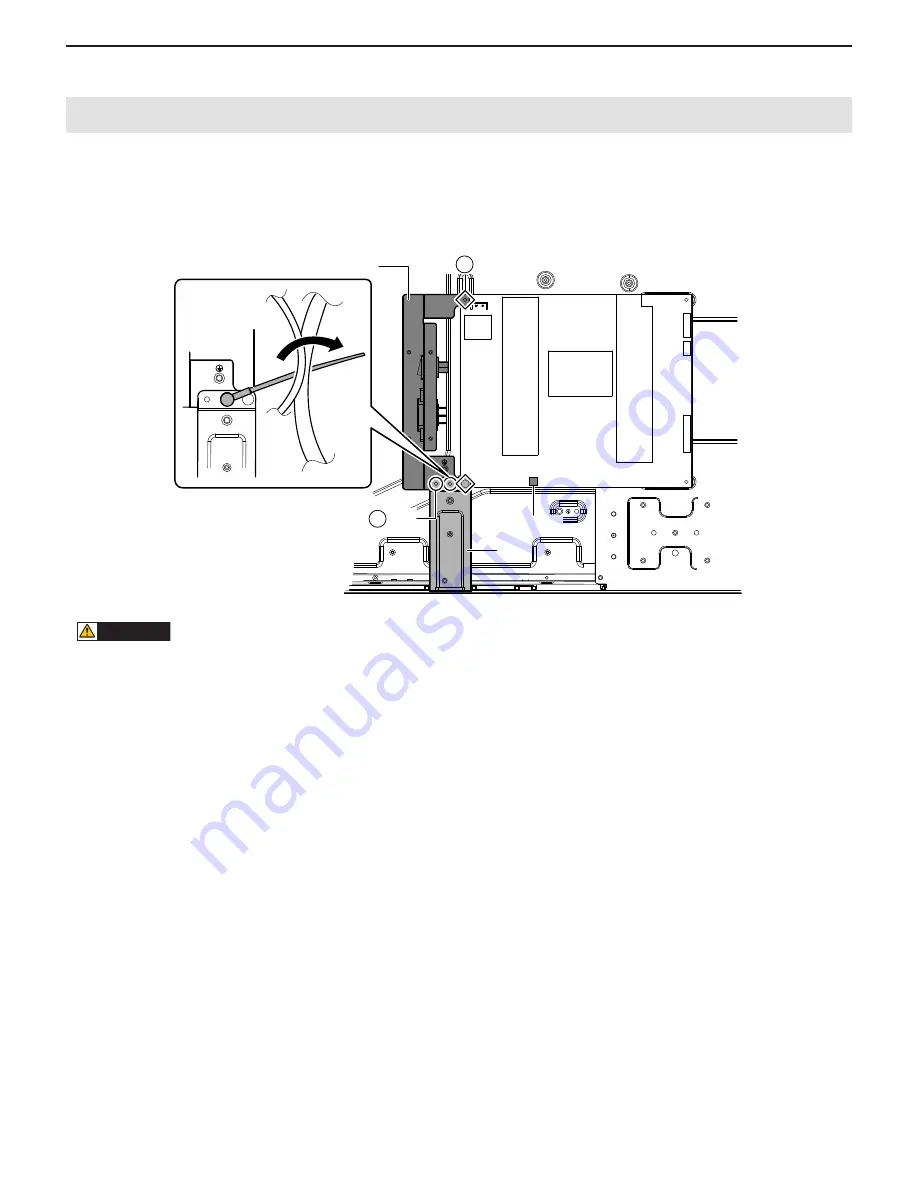

5. INLET HARNESS/AC SWITCH

1 ) Disconnect 1connector, and remove the cable band.

2 ) Unscrew 2pcs of screw

A

(3 x 6 (silver)), and remove the plate. Unscrew 2pcs of screw

B

(3 x 6 (silver)), and remove the AC inlet/ AC switch

assy.

CAUTION

SCREW TIGHTENING TORQUE

n

0.5 - 0.6N•m

A

B

AC inlet/ AC switch assy

Cable band

Screw

x 2

Screw

x 2

Connector

Plate