119

6 RI

Robot interface

7

Software

versions

8 ON

System operation time

9 WELDING System welding time

At this stage the gas test is also carried out to check the proper

connection to the gas supply system.

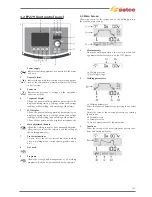

3.4 Main Screen

Allows the control of the system and of the welding process,

showing the main settings.

1 Welding parameters

2

Functions

1 Welding

parameters

1a Welding parameters

Select the required parameter by pressing the encoder button.

Adjust the value of the selected parameter by rotating

the encoder.

1b Parameter icon

1c Parameter value

1d Unit of measurement of the parameter

The parameters of the main screen can be personalised (consult

the “Interface personalisation” section).

2 Functions

Allow the setting of the most important process func-

tions and welding methods.

2a

Allows the selection of the welding process

MMA

TIG

DC

TIG

AC

2b

MMA

Allows the selection of the welding method

Direct polarity

Reverse polarity

Alternating current

TIG

Allows the selection of the welding method

2 Step

4 Step

Bilevel

2c

MMA

Synergy

Allows you to set the best arc dynamics,

selecting the type of electrode used:

STD

Basic/Rutile

CLS

Cellulose

CrNi

Steel

Alu

Aluminium

Cast iron Cast iron

Selecting the correct arc dynamics enables maximum

benefit to be derived from the power source to achieve

the best possible welding performances.

Perfect weldability of the electrode used is not guaran-

teed (weldability depends on the quality of the consum-

ables and their preservation, the operating and welding

conditions, the numerous possible applications, etc.).

TIG DC

Current pulsation

CONSTANT current

PULSED current

Fast Pulse

TIG AC

Current pulsation

CONSTANT current

PULSED current

AC/DC mix

2d

Allows the storage and management of 60

welding programs which can be personalised

by the operator.

(Consult the “Programs screen” section).

Summary of Contents for Genesis 1700 AC/DC

Page 1: ...Genesis 1700 AC DC Genesis 2200 AC DC MANUALE DI RIPARAZIONE REPAIR MANUAL ...

Page 51: ...161 PFC S POWER COMPONENTS D11 IG1 IG2 D1 D7 CN3 M1 CN4 CN5 CN8 CN7 M2 CN6 ...

Page 52: ...162 PFC STAGE LEDS INDICATIONS PFC s POWER COMPONENTS L2 L1 IG1 IG2 D1 CN6 D7 D11 ...

Page 54: ...164 INVERTER STAGE CN3 M1 CN4 CN5 CN8 CN7 M2 Inverter IMS power module ...

Page 62: ...172 15 Remove pcb T3 PFC s POWER COMPONENTS IG1 IG2 D1 NTC1 Unscrew torque screw at 2 2N mt ...

Page 64: ...174 DIODES AND PFC IGBT ORIENTATION Landmark for assembling ...

Page 67: ...177 12 4 Thermic caps inverter side NTC1 T3 CN11 ...

Page 69: ...179 12 5 Thermic caps secondary side T1 T2 15 14 434 CN3 CN2 ...

Page 74: ...184 15 14 439 15 14 42901 L3 L4 L1 L2 ...

Page 75: ...185 Gas valve flow chart signal Pipe 38 39 ...

Page 79: ...189 CN6 15 14 415 CN3 15 14 431 FLAT A FLAT B Inverter commands Boost commands ...

Page 80: ...190 By pass relais flow chart Gas valve ELVI Fan M1 and M2 command signal ...

Page 81: ...191 HF command signal AC command signal Torch switch buttons signals ...

Page 88: ...198 HF pulse in TIG AC HF pulse in TIG DC ...

Page 114: ...224 GENESIS 2200 AC DC FP279 ...

Page 115: ...225 GENESIS 1700 AC DC FP216 ...

Page 116: ...226 GENESIS 2200 AC DC FP216 ...

Page 118: ...228 20 CONNETTORI CONNECTORS GENESIS 1700 AC DC FP279 GENESIS 2200 AC DC FP279 ...

Page 119: ...229 GENESIS 1700 AC DC FP216 GENESIS 2200 AC DC FP216 ...

Page 122: ...232 55 08 022 55 08 023 GENESIS 1700 AC DC FP216 GENESIS 2200 AC DC FP216 ...