121

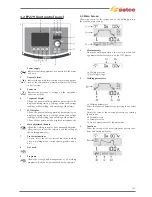

List of set up parameters (TIG)

0

Save and quit

Allows you to save the changes and exit the set up.

1

Reset

Allows you to reset all the parameters to the default

values.

2 Pre-gas

Allows you to set and adjust the gas flow prior to striking

of the arc.

Permits filling of the torch with gas and preparation of

the environment for welding.

Minimum 0.0sec., Maximum 99.9sec., Default 0.1sec.

3 Initial

current

Allows regulation of the weld starting current.

Allows a hotter or cooler welding pool to be obtained

immediately after the arc striking.

Parameter setting: Amperes (A) - Percentage (%).

Minimum 3A-1%, Maximum Imax-500%, Default 50%

5

Initial current time

Allows setting of the time for which the initial current is

maintained.

Parameter setting: seconds (s).

Minimum off, Maximum 99.9s, Default off

6 Slope-up

Allows you to set a gradual passage between the initial

current and the welding current. Parameter set in sec-

onds (s).

Minimum off, Maximum 99.9s, Default off

7 Welding

current

Permits adjustment of the welding current.

Parameter set in Amps (A).

Minimum 3A, Maximum Imax, Default 100A

8 Bilevel

current

Permits adjustment of the secondary current in the

bilevel welding mode.

Parameter set in Amps (A).

Minimum 3A-1%, Maximum Imax-100%, Default 50%

10

Basic current

Permits adjustment of the basic current in pulsed and

fast pulse modes.

Parameter set in Amps (A).

Minimum 3A-1%, Maximum Weld current-100%,

Default 50%

12 Pulsed

frequency

Allows activation of the pulse mode.

Allows regulation of the pulse frequency.

Allows better results to be obtained in the welding of

thin materials and better aesthetic quality of the bead.

Parameter setting: Hertz (Hz) - KiloHertz (kHz).

Minimum 0.1Hz, Maximum 250Hz, Default off

13

Pulsed duty cycle

Allows regulation of the duty cycle in pulse welding.

Allows the peak current to be maintained for a shorter

or longer time.

Parameter setting: percentage (%).

Minimum 1%, Maximum 99%, Default 50%

14

Fast Pulse frequency

Allows regulation of the pulse frequency.

Allows focusing action and better stability of the elec-

tric arc to be obtained.

Parameter setting: KiloHertz (kHz).

Minimum 0.02KHz, Maximum 2.5KHz, Default off

15 Pulsed

slopes

Allows setting of a slope time during the pulse operation.

Allows a smooth step to be obtained between the peak

current and the basic current, having a more or less soft

welding arc.

Parameter setting: percentage (%).

Minimum off, Maximum 100%, Default off

16 Slope-down

Allows you to set a gradual passage between the weld-

ing current and the final current.

Parameter set in seconds (s).

Minimum off, Maximum 99.9s, Default off

17 Final

current

Permits adjustment of the final current.

Parameter set in Amps (A).

Minimum 3A-1%, Maximum Imax-500%, Default 50%

19

Final current time

Makes it possible to set the time for which the final cur-

rent is maintained.

Parameter setting: seconds (s).

Minimum off, Maximum 99.9s, Default off

20 Post-gas

Permits setting and adjustment of the gas flow at the

end of welding.

Minimum 0.0s, Maximum 99.9s, Default syn

101

(TIG AC) AC wave form

Allows the selection of the required AC wave form.

Default

102

(TIG AC) AC frequency

Allows regulation of the polarity inversion frequency in

TIG AC welding.

Allows focusing action and better stability of the electric

arc to be obtained.

Parameter setting: Hertz (Hz).

Minimum 20Hz, Maximum 200Hz, Default 100Hz

103

(TIG AC) AC balance

Allows regulation of the duty cycle in TIG AC welding.

Allows the positive polarity to be maintained for a

longer or shorter time.

Parameter setting: percentage (%).

Minimum 15%, Maximum 65%, Default 35%

104

(TIG AC) Fuzzy logic

Allows regulation of the power delivered by the system

during the arc striking phase by selecting the electrode

diameter used.

Makes it possible to suitably heat the electrode and/or

to keep the tip intact.

Parameter setting: millimetres (mm).

Minimum 0.1mm, Maximum 5.0mm, Default 2.4mm

105 Easy

rounding

Allows a greater amount of energy to be delivered dur-

ing the TIG AC arc striking phase.

Allows the rounding of the electrode in a uniform and

regular manner.

The function is automatically disabled after the arc has

been struck.

The power delivered depends on the electrode diam-

eter set on the fuzzy logic.

Default

off

107

AC - DC time mix

Allows adjustment of the welding time in direct current

when the AC MIX function is enabled.

Parameter setting: seconds (s).

Minimum 0.02s, Maximum 2.00s, Default 0.24s

Summary of Contents for Genesis 1700 AC/DC

Page 1: ...Genesis 1700 AC DC Genesis 2200 AC DC MANUALE DI RIPARAZIONE REPAIR MANUAL ...

Page 51: ...161 PFC S POWER COMPONENTS D11 IG1 IG2 D1 D7 CN3 M1 CN4 CN5 CN8 CN7 M2 CN6 ...

Page 52: ...162 PFC STAGE LEDS INDICATIONS PFC s POWER COMPONENTS L2 L1 IG1 IG2 D1 CN6 D7 D11 ...

Page 54: ...164 INVERTER STAGE CN3 M1 CN4 CN5 CN8 CN7 M2 Inverter IMS power module ...

Page 62: ...172 15 Remove pcb T3 PFC s POWER COMPONENTS IG1 IG2 D1 NTC1 Unscrew torque screw at 2 2N mt ...

Page 64: ...174 DIODES AND PFC IGBT ORIENTATION Landmark for assembling ...

Page 67: ...177 12 4 Thermic caps inverter side NTC1 T3 CN11 ...

Page 69: ...179 12 5 Thermic caps secondary side T1 T2 15 14 434 CN3 CN2 ...

Page 74: ...184 15 14 439 15 14 42901 L3 L4 L1 L2 ...

Page 75: ...185 Gas valve flow chart signal Pipe 38 39 ...

Page 79: ...189 CN6 15 14 415 CN3 15 14 431 FLAT A FLAT B Inverter commands Boost commands ...

Page 80: ...190 By pass relais flow chart Gas valve ELVI Fan M1 and M2 command signal ...

Page 81: ...191 HF command signal AC command signal Torch switch buttons signals ...

Page 88: ...198 HF pulse in TIG AC HF pulse in TIG DC ...

Page 114: ...224 GENESIS 2200 AC DC FP279 ...

Page 115: ...225 GENESIS 1700 AC DC FP216 ...

Page 116: ...226 GENESIS 2200 AC DC FP216 ...

Page 118: ...228 20 CONNETTORI CONNECTORS GENESIS 1700 AC DC FP279 GENESIS 2200 AC DC FP279 ...

Page 119: ...229 GENESIS 1700 AC DC FP216 GENESIS 2200 AC DC FP216 ...

Page 122: ...232 55 08 022 55 08 023 GENESIS 1700 AC DC FP216 GENESIS 2200 AC DC FP216 ...