Tech Service Bulletin No. A230/A231/A232 – 037

Page 3 of 4

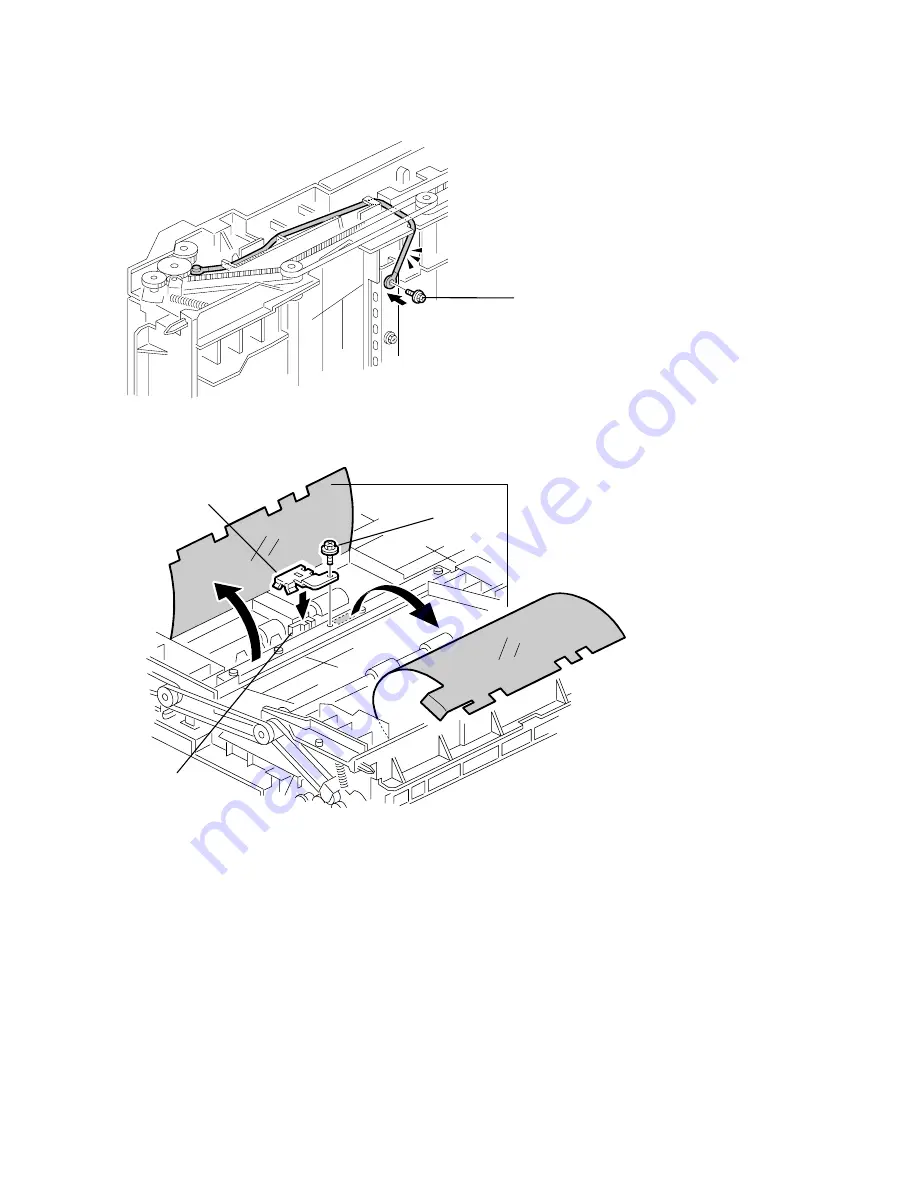

5. Route the Harness under the Drive Belt as shown in the illustration, taking up any

slack.

6. Secure the other end of the Harness with the Screw [E] that secures the Stay.

7. Peel back the 2 strips of Mylar [A] attached to the Stay as shown in the illustration above.

8. Peel back the two-sided tape remaining on the Stay (approximately 4cm total,

centered around the Sensor [B]).

9. Remove the Screw [C] (securing the Stay) that is closest to the Sensor.

10. Place the new Plate Spring [D] (A6883914) over the Sensor, return the Mylar and

fasten with the Screw removed in step 9.

NOTE

: Since there is a possibility of the roller slipping, clean the three Transport Rollers with alcohol or a

damp cloth.

Continued…

[A]

[C]

[D]

[B]

[E]

Summary of Contents for A230

Page 1: ...SERVICE MANUAL 000861MIU A230 A231 A232 RICOH GROUP COMPANIES ...

Page 2: ...SERVICE MANUAL A230 A231 A232 RICOH GROUP COMPANIES ...

Page 3: ...A230 A231 A232 SERVICE MANUAL 000861MIU ...

Page 4: ......

Page 6: ......

Page 8: ......

Page 10: ......

Page 35: ......

Page 39: ......

Page 40: ...OVERALL MACHINE INFORMATION ...

Page 41: ......

Page 62: ...DETAILED SECTION DESCRIPTIONS ...

Page 63: ......

Page 139: ......

Page 140: ...INSTALLATION ...

Page 141: ......

Page 208: ...SERVICE TABLES ...

Page 209: ......

Page 280: ...PREVENTIVE MAINTENANCE ...

Page 281: ......

Page 285: ...REPLACEMENT AND ADJUSTMENT ...

Page 286: ......

Page 343: ...TROUBLESHOOTING ...

Page 344: ......

Page 383: ...PAPER TRAY UNIT A682 ...

Page 384: ......

Page 403: ...LARGE CAPACITY TRAY A683 ...

Page 404: ......

Page 419: ...BY PASS A689 ...

Page 420: ......

Page 433: ... 1 BIN TRAY A684 ...

Page 434: ......

Page 442: ......

Page 443: ...AUTO DOCUMENT FEEDER A680 ...

Page 444: ......

Page 468: ...ROM HISTORY 12 22 A230 A231 A232 SM B Rev 09 2000 ...

Page 477: ...INTERCHANGE UNIT A690 ...

Page 478: ......

Page 484: ......

Page 485: ... DUPLEX A687 ...

Page 486: ......

Page 498: ......

Page 499: ...BRIDGE UNIT A688 ...

Page 500: ......

Page 507: ...1 000 SHEET FINISHER A681 ...

Page 508: ......

Page 534: ......

Page 535: ...3 000 SHEET FINISHER A697 ...

Page 536: ......

Page 571: ...SwapBox and SwapFTL Installation Manual ...

Page 572: ......

Page 583: ...SwapFTL Binary Utility Operation Manual ...

Page 584: ......

Page 595: ...SM A203 231 A232 19 11 3 4 HELP MENU 3 4 1 HELP ABOUT SWAPUTI SwapBox And SwapFTL FUNCTIONS ...

Page 596: ......

Page 597: ...NINE TRAY MAILBOX AND BRIDGE UNIT G909 G912 ...

Page 598: ......

Page 627: ...SCANNER KIT A695 ...

Page 628: ......

Page 658: ......

Page 660: ......

Page 672: ......

Page 710: ......

Page 817: ......

Page 831: ......

Page 853: ...TECHNICAL SERVICE BULLETINS ...

Page 857: ...ISDN Unit A816 ...

Page 858: ......

Page 864: ......

Page 880: ......

Page 900: ......

Page 904: ......

Page 908: ......

Page 909: ...TECHNICAL SERVICE BULLETINS ...

Page 922: ...SwapFTL and SwapFTL Installation Manual ...

Page 933: ...SwapFTL Binary Utility Operation Manual ...

Page 944: ...SM A203 231 A232 19 11 3 4 HELP MENU 3 4 1 HELP ABOUT SWAPUTI SwapBox And SwapFTL FUNCTIONS ...

Page 1074: ......

Page 1096: ......