8-9

8.1.4 Setting and Operation of J Point Control

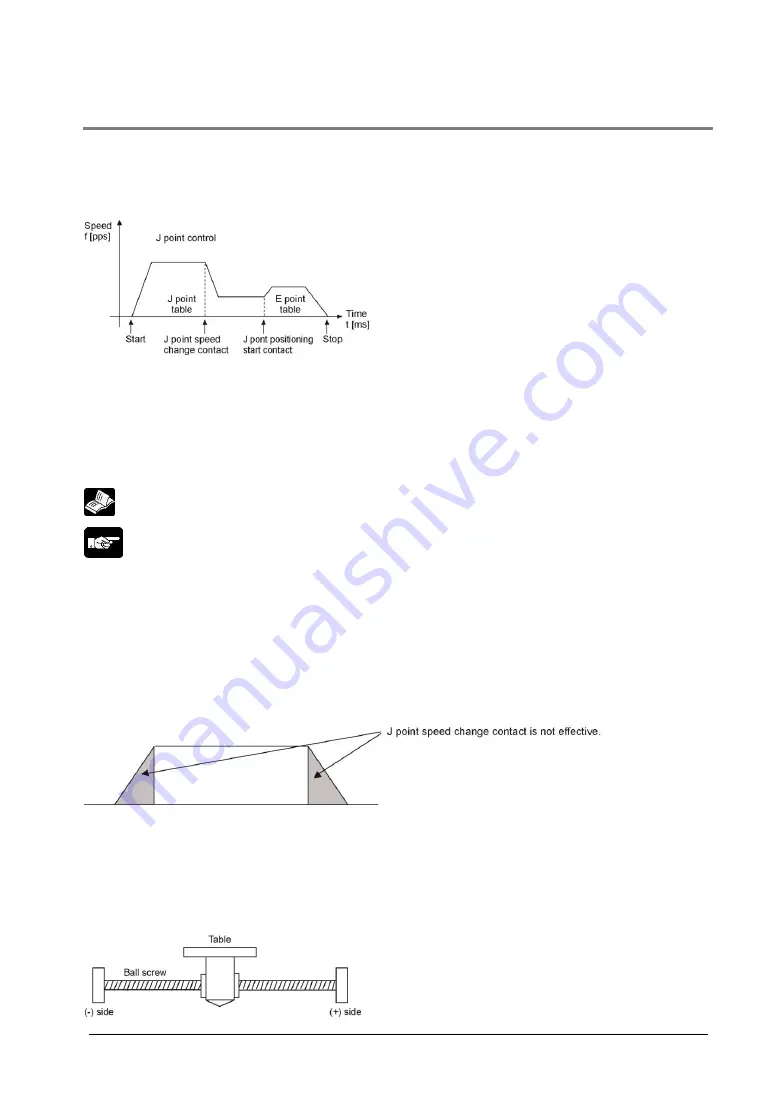

The J point control is performed at the target speed from the beginning of the operation until the J point

positioning start contact turns on, and once the contact turns on, the next position control will be started.

The J point control can be used only for a single axis control. Note that it cannot be used for the

interpolation control.

In the J point control, the speed can be changed during the operation. To change the speed, turn on the

J point speed change contact after changing the following parameters in the parameter setting area.

- J point control code

- J point acceleration time

- J point deceleration time

- J point target speed

Reference:

<17.6.2 Parameter Setting Area>

Note:

The control code, acceleration (deceleration) time and target speed when starting the J point control are

activated by each setting of the table that the J pont control has been specified.

The J point control code, J point acceleration (deceleration) time and J point target speed will become

effective when the speed for the J point control is changed.

Precautions when performing the J point control

In the J point control, although the speed can be changed during the operation, it cannot be changed

when accelerating (decelerating). The contact for changing the speed when accelerating (decelerating)

is ignored, and the speed changes when operating at the constant speed.

Use the increment mode for the position setting method for the P point, C point and E point controls to

be executed after the J point control.

The speed control is performed in the J point contor, however, the positioning moving amount should be

always a value that enables to have a constant speed area at the target speed.

The example below is the case of a single axis control with the positioning unit installed in the slot 0. The

movement amount setting is the increment method, and the unit is set to pulse.

Summary of Contents for AFP243710

Page 16: ...xiv ...

Page 17: ...Chapter 1 Functions of Unit and Restrictions on Combination ...

Page 21: ...Chapter 2 Parts and Functions ...

Page 24: ...2 4 ...

Page 25: ...Chapter 3 Wiring ...

Page 39: ...Chapter 4 Power On Off and Items to Check ...

Page 44: ...4 6 ...

Page 45: ...Chapter 5 Preparation For Operation ...

Page 53: ...5 9 ...

Page 55: ...Chapter 6 I O Allocation ...

Page 63: ...Chapter 7 Setting Tool Configurator PM ...

Page 87: ...7 25 Setting Font Select Option Font in the menu bar The following dialog is shown ...

Page 102: ...7 40 ...

Page 103: ...Chapter 8 Automatic Operation Position Control ...

Page 115: ...8 13 ...

Page 116: ...8 14 When the X axis and Y axis is the moving axes each axis in the above diagram is replaced ...

Page 129: ...8 27 Reference Chapter 10 Manual Operation Home Return ...

Page 139: ...Chapter 9 Manual Operation JOG Operation ...

Page 144: ...9 6 ...

Page 145: ...Chapter 10 Manual Operation Home Return ...

Page 151: ...Chapter 11 Manual Operation Pulser Operation ...

Page 155: ...Chapter 12 Stop Functions ...

Page 158: ...12 4 ...

Page 159: ...Chapter 13 Supplementary Functions ...

Page 171: ...Chapter 14 Precautions During Programming ...

Page 175: ...Chapter 15 Errors and Warnings ...

Page 186: ...15 12 ...

Page 187: ...Chapter 16 Troubleshooting ...

Page 190: ...16 4 ...

Page 191: ...Chapter 17 Specifications ...

Page 241: ...Chapter 18 Dimensions ...

Page 242: ...18 2 18 1 FP2 Positioning Unit Interpolation Type 2 axis type Unit mm 4 axis type Unit mm ...

Page 243: ...Chapter 19 Sample Programs ...

Page 247: ...19 5 ...

Page 250: ...19 8 ...

Page 251: ...Chapter 20 Driver Wiring ...

Page 261: ......