6-10 Troubleshooting

Other Messages

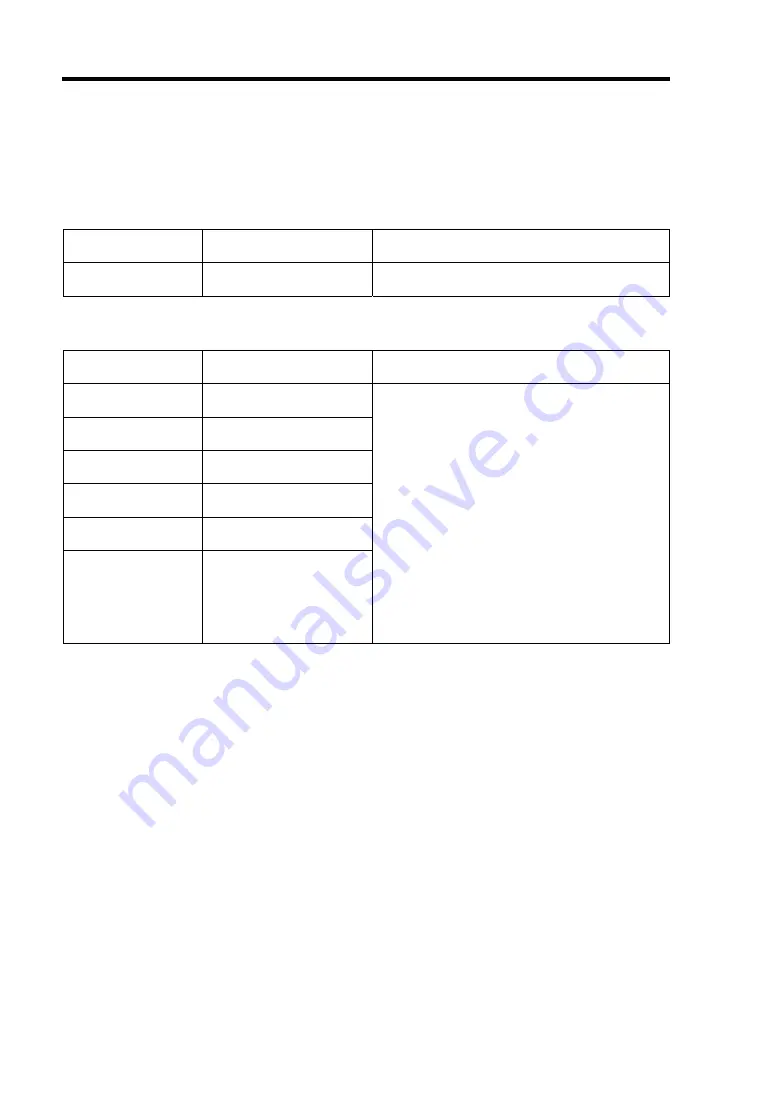

Messages displayed on upper line

When STATUS lamp is lighting in green:

On-screen

message

Description

Action

Prepare To Boot

POST completes

normally.

This is not an error.

When STATUS lamp is off:

On-screen

message

Description

Action

PCI Bus SERR 01

A system error was

detected on chipset.

PCI Bus SERR 07

A system error was

detected on LAN1 device.

PCI Bus SERR 09

A system error was

detected on LAN2 device.

PCI Bus PERR 01

A system error was

detected on chipset.

PCI Bus PERR 07

A system error was

detected on LAN1 device.

PCI Bus PERR 09

A system error was

detected on LAN2 device.

1. Take one of the following measures to

reboot (reset) the maintenance card.

* Press

Ctrl

+

Alt

+

Del

.

* Issue a command from Web browser of

EXPRESSSCOPE Engine 2 or NEC

ESMPRO Manager.

2. Take one of the following measures to power

off the maintenance card and then on.

* Press the Maintenance switch to power off

the maintenance card, then press it again

to power on.

* Issue a command from Web browser of

EXPRESSSCOPE Engine 2 or NEC

ESMPRO Manager.

3. If the same error persists, contact your

service representative.

Summary of Contents for EcoPowerGateway N8142-36F

Page 4: ......

Page 6: ......

Page 8: ......

Page 10: ... This page is intentionally left blank ...

Page 16: ...vi This page is intentionally left blank ...

Page 21: ...Notes on Using Your EcoPowerGateway 1 5 ...

Page 23: ...Notes on Using Your EcoPowerGateway 1 7 ...

Page 26: ...1 10 Notes on Using Your EcoPowerGateway ...

Page 29: ...Notes on Using Your EcoPowerGateway 1 13 ...

Page 38: ...1 22 Notes on Using Your EcoPowerGateway This page is intentionally left blank ...

Page 56: ...2 18 General Description This page is intentionally left blank ...

Page 136: ...A 2 Specifications This page is intentionally left blank ...