WWW.NNC.IR

2 - 4

2. INSTALLATION

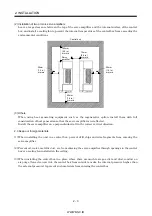

2.4 Cable stress

(1) The way of clamping the cable must be fully examined so that flexing stress and cable's own mass

stress are not applied to the cable connection.

(2) For use in any application where the servo motor moves, fix the cables (encoder, power supply, brake)

supplied with the servo motor, and flex the optional encoder cable or the power supply and brake

wiring cables. Use the optional encoder cable within the flexing life range. Use the power supply and

brake wiring cables within the flexing life of the cables.

(3) Avoid any probability that the cable sheath might be cut by sharp chips, rubbed by a machine corner

or stamped by workers or vehicles.

(4) For installation on a machine where the servo motor will move, the flexing radius should be made as

large as possible. Refer to section 12.4 for the flexing life.

Summary of Contents for MR-J2S-*A

Page 13: ...WWW NNC IR A 12 MEMO ...

Page 117: ...WWW NNC IR 3 70 3 SIGNALS AND WIRING MEMO ...

Page 185: ...WWW NNC IR 7 12 7 GENERAL GAIN ADJUSTMENT MEMO ...

Page 195: ...WWW NNC IR 8 10 8 SPECIAL ADJUSTMENT FUNCTIONS MEMO ...

Page 197: ...WWW NNC IR 9 2 9 INSPECTION MEMO ...

Page 221: ...WWW NNC IR 11 10 11 OUTLINE DIMENSION DRAWINGS MEMO ...

Page 293: ...WWW NNC IR 13 64 13 OPTIONS AND AUXILIARY EQUIPMENT MEMO ...

Page 321: ...WWW NNC IR 14 28 14 COMMUNICATION FUNCTIONS MEMO ...

Page 389: ...WWW NNC IR 15 68 15 ABSOLUTE POSITION DETECTION SYSTEM MEMO ...